483

WIRING DEVICES

Technical Hotline

+44 (0)1268 563720

For a full range of corresponding products,

see pages 98-128 in the product selector.

Aspect Installation

Wiring Devices Technical

– Aspect

The MK ‘Aspect’ range of products consists of the main product

complete with its support frame and clipping medium, plus a

separate frontplate. The product is mounted to the wall, after

wiring, and the front plate clipped onto the frame.

1.

The frontplate is supplied loose to aid installation.

2.

Make sure not to crush or deform the spring steel clips situated

along one edge of the product support frame.

3.

A gasket is also supplied with each product, which may prove

useful on uneven walls. See note 5 below.

4.

Using the gasket with all switches and the German socket, will

ensure full compliance with the appropriate standards.

5.

Both standards set out to guarantee full engagement of the

frontplate on uneven surfaces, even when there is a mismatch

of as much as 1mm between the distance the main body of the

product is from the wall and that of the front plate.

6.

Where no gasket is used, if thick wallpapers are cut such that

they fit around the support frame and therefore remain under

the edge of the frontplate, full plate engagement with the clips

may be restricted.

Note:

When installing Aspect do not over tighten screws, so as to prevent

damage or distortion to the product or support frame.

Frontplate Removal

1.

Turn off the power supply.

2.

Carefully slide a screwdriver between the ramp on the main

body of the product and the notch in the lower right hand edge

of the plate.

3.

On uneven walls, make sure the screwdriver does not go

between the spring steel ramp and the wall, or damage to the

wall and/or product could result.

4.

Carefully slide the blade upwards and then gently lift the

handle away from the wall, which will lever the plate away from

the first clip. See Fig.4.

5.

With the first clip released, support the plate with one hand and

continue to move the blade to the left under.

Data products in euromounting frames

Products operating at extra low voltage levels (<50v) must not

be mounted in the same Euro enclosures as equipment rated in

excess of 50v.

Cleaning Frontplates

In order to protect the quality surface finish of the front plate,

periodic cleaning should only consist of polishing with a dry lint

free soft cloth.

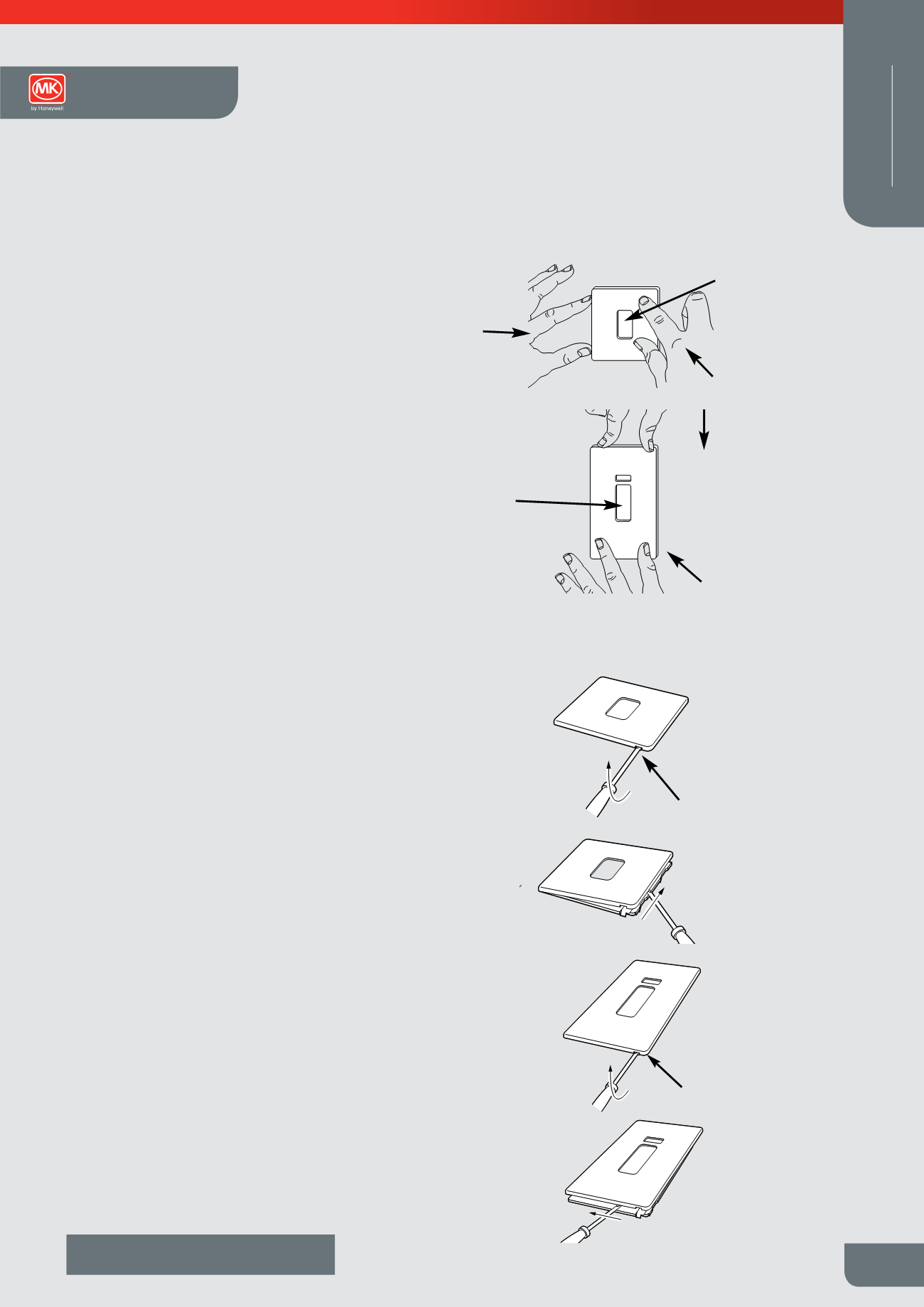

Figure 1a

Adjust

North/South

to align with

plate aperture

Apply a force

in this

direction

Force applied

towards the

wall

Figure 1b

Adjust

North/South to

align with plate

aperture

Apply a

force in this

direction

Force applied

towards the

wall

Gently lever

away from

wall

Blade to be

between notch in

plate and ramp on

support frame

Figure 2

Figure 3

Slide screwdriver

up to disengage

other clip

Gently lever

away from

wall

Blade to be

between notch in

Figure 4

Figure 1a

Adjust

North/South

to align with

plate aperture

Apply a force

in this

direction

Force applied

towards the

wall

Figure 1b

Adjust

North/South to

align with plate

aperture

Apply a

force in this

direction

Force applied

towards the

wall

Gently lever

away from

wall

Blade to be

between notch in

plate and ramp on

support frame

Figure 2

Figure 3

Slide screwdriver

up to disengage

other clip

Gently lever

away from

wall

Blade to be

between notch in

plate and ramp on

support frame

Figure 4

i re

A just

Nort / out

t ali n it

lat a ert r

pply f rce

i t is

direction

F rce

li

t w rds t e

all

i ur 1b

j st

rt /

t to

align ith plate

aperture

Apply a

force in this

direction

orce applied

to ards the

all

tly l v r

y fr

ll

l de to be

et e tch i

l te an r

su ort fr

ig r 2

i r

li

scr

riv r

t is

t r cli

tly l v r

y fr

ll

l

t

t

tc i

plate and ramp on

support frame

i r

Figure 1a

Adjust

North/South

to align with

plate aperture

Apply a force

in this

direction

Force applied

towards the

wall

Figure 1b

Adjust

North/South to

align with plate

aperture

Apply a

force in this

direction

Force applied

towards the

wall

Gently lever

away from

wall

Blade to be

between notch in

plate and ramp on

support frame

Figure 2

Figure 3

Slide screwdriver

up to disengage

other clip

Gently lever

away from

wall

Blade to be

between notch in

plate and ramp on

support frame

Figure 4

Figure 5

Figure 1a

Adjust

North/South

to align with

plate aperture

Apply a force

in this

direction

Force applied

towards the

wall

Figure 1b

Adjust

North/South to

align with plate

aperture

App y a

forc in this

direction

Force applied

towards the

wall

Gently lever

away from

wall

Blade to be

between notch in

plate and ramp on

support frame

Figure 2

Figure 3

Slide screwdriver

up to disengage

other clip

Gently lever

away from

wall

Blade to be

between notch in

plate and ramp on

support frame

Figure 4

Slide screwdriver

to the left to

disengage other clip

Figure 5

to align with

plate aperture

Apply a force

in this

direction

Force applied

towards the

wall

Figure 1b

Adj st

North/South to

align with plate

aperture

Apply a

forc in this

direction

Forc plied

towards the

wall

Gently lever

away from

wall

Blade to be

between notch in

plate and ramp on

support frame

Figure 2

3

Slide screwdriver

up to disengage

other clip

Gently lever

away from

wall

Blade to be

between notch in

plate and ramp on

support frame

Figure 4

Slide screwdriver

to the left to

disengage other clip

Figure 5

FIGURE 1A

FIGURE 2

FIGURE 3

FIGURE 4

FIGURE 5

FIGURE 1B

Frontplate Installation

Frontplate Removal