4/52

Presentation

The Premium Hot Standby offer, compatible with Unity Pro software, ensures

continuity of operation of a Modicon Premium automation platform control system in

the event of failure of:

b

The central processing and communication functions

b

All or part of the I/O system

It is based on the principle of Primary/Standby redundancy with complete redundancy

of the main processing and communication functions, use of shared I/O on the

Ethernet TCP/IP network, the Modbus link and/or redundancy of in-rack I/O

(

single-rack or multi-rack configuration).

Premium Hot Standby redundant architectures offer an optimum solution for

responding to requirements for availability where changeover times are not critical.

They are suitable for processes which can tolerate a lack of control, on the part of the

Premium control unit, lasting a maximum of around one second (typical duration

corresponding to the changeover time from the Primary unit to the Standby unit and

the time it takes the shared I/O on Ethernet to refresh).

It covers all the requirements for availability when the PLC's mission is to monitor

and control an installation in continuous duty, indicate problems to a control station,

and send the supervision manager's control instructions to various locations on an

extensive site.

Examples of areas of application:

b

Building management system for a public site (tunnel, airport, signalling, etc.)

b

Control and monitoring of water treatment or desalination plant

b

Electrical management system

b

Production of hydro-electric power, etc.

Principle

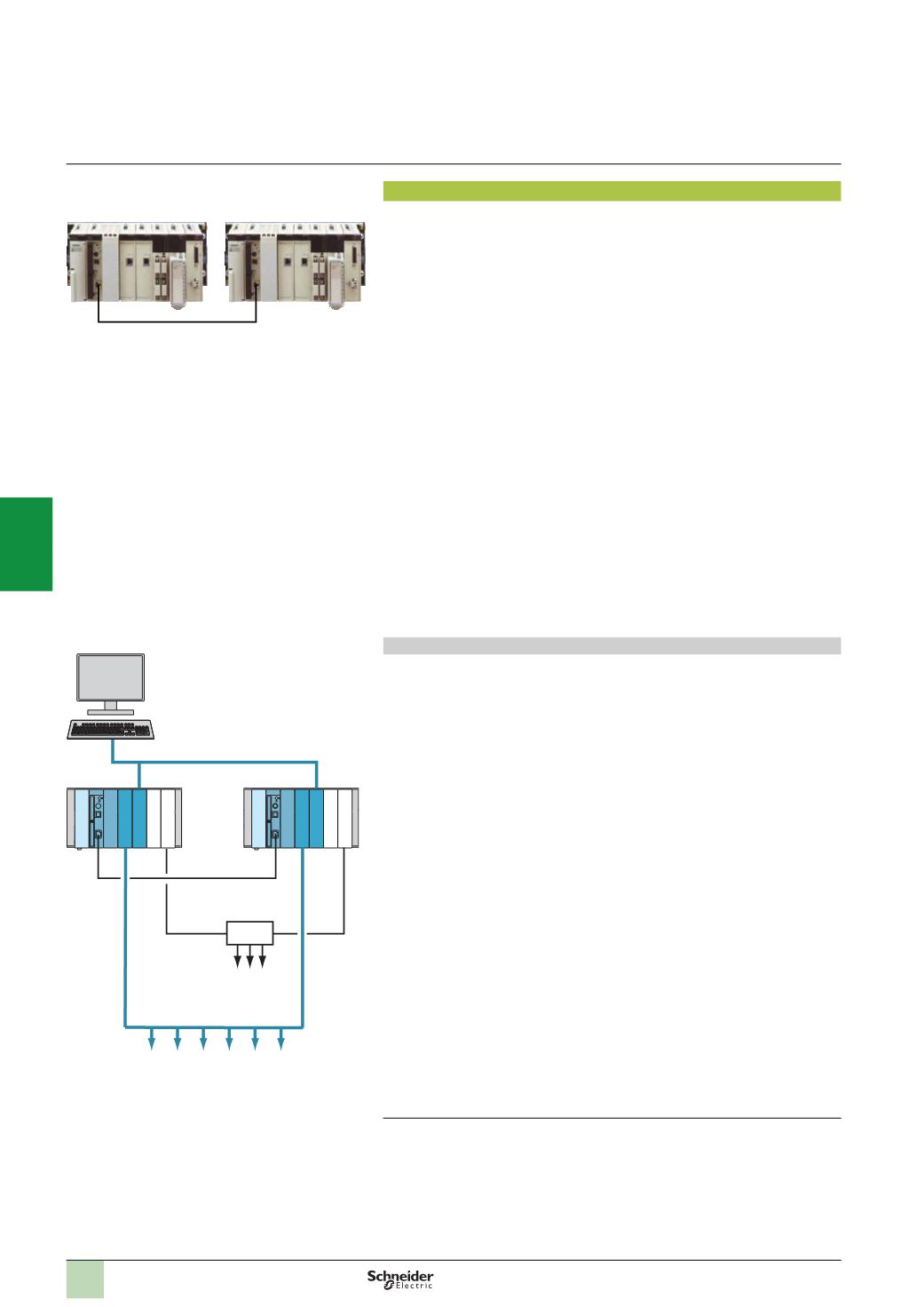

At the heart of the system there are 2 single-rack or multi-rack

(1)

Modicon Premium

configurations, known as the Primary PLC and the Standby PLC. They have

identical hardware and software configurations (identical modules in each rack). The

offer comprises two processor models,

TSX H57 24M

and

TSX H57 44M

,

dedicated

to Hot Standby architectures with Unity Pro software (version

u

3.1

in single-rack

configuration and

u

5.0

in multi-rack configuration).

These double format processors combine the central processing unit and redundant

coprocessor functions in the same housing.

The Primary PLC:

b

Executes the application program and controls the I/O which may be:

v

Field products on the Ethernet network managed by the I/O Scanning service

(

see page 5/32)

v

Field products on the Modbus master link

v

Sensors and actuators connected to the Premium I/O modules on Bus X in a

single-rack or multi-rack configuration

b

Transfers all its data to the Standby PLC via the CPU Sync link at the start of each

scan

In the event of failure of the Primary PLC, the standby system switches over

automatically, taking 1.5 PLC scan cycles, changing over execution of the application

program and control of the I/O to the Standby PLC with an up-to-date data context.

The Ethernet network modules of both Premium configurations managing the field

products exchange their addresses by means of an automatic “IP” and “IP + 1”

address assignment mechanism. This mechanism applies to Modbus link modules

with assignment of the slave addresses “n” and “n + 1”.

Once they have changed over, the “Standby” PLC becomes the “Primary” PLC.

Once the faulty PLC has been repaired and reconnected to the standby system,

it takes the role of the Standby PLC.

(1)

The latest version of

TSX H57 24M/44M

Hot Standby processors incorporates the firmware

for the V2.83 PLC operating system and the Ethernet V2.82 coprocessor which is used to

configure multi-rack Hot Standby applications in Unity Pro V5.0. Up-to-date versions of these

firmware programs are available on our website

www.schneider-electric.com.

Ethernet

Ethernet

I/O

I/O

Ethernet

Ethernet

I/O

I/O

SCADA

Standby

Premium

Ethernet Modbus/TCP

Primary

Premium

Sensors/actuators

CPU Sync link

Field products on Ethernet Modbus/

TCP network (I/O Scanning)

2

to 1

Presentation

Primary Modicon Premium Standby Modicon Premium

CPU Sync link

Modicon Premium automation

platform

0

Hot Standby system

Unity Pro software

2

1

3

4

5

6

7

8

9

10