Tel

+44 (0)1424 856600

Fax

+44 (0)1424 856611

Technical Hotline

+44 (0)1424 856688

TECHNICAL INFORMATION

Technical information

296 |

Aluminium trunking systems

Material

Aluminium trunking is manufactured

from high precision extruded

aluminium with a powder coat finish.

Accessory boxes are supplied in PVC-U

or polycarbonate both of which are

100% recyclable.

Installation

Positioning

For dado and skirting installation. When

used as a skirting system, sufficient

clearance should be allowed between

the floor covering and the profile

fittings that clip over the cover i.e. 5mm

+ floor covering is recommended.

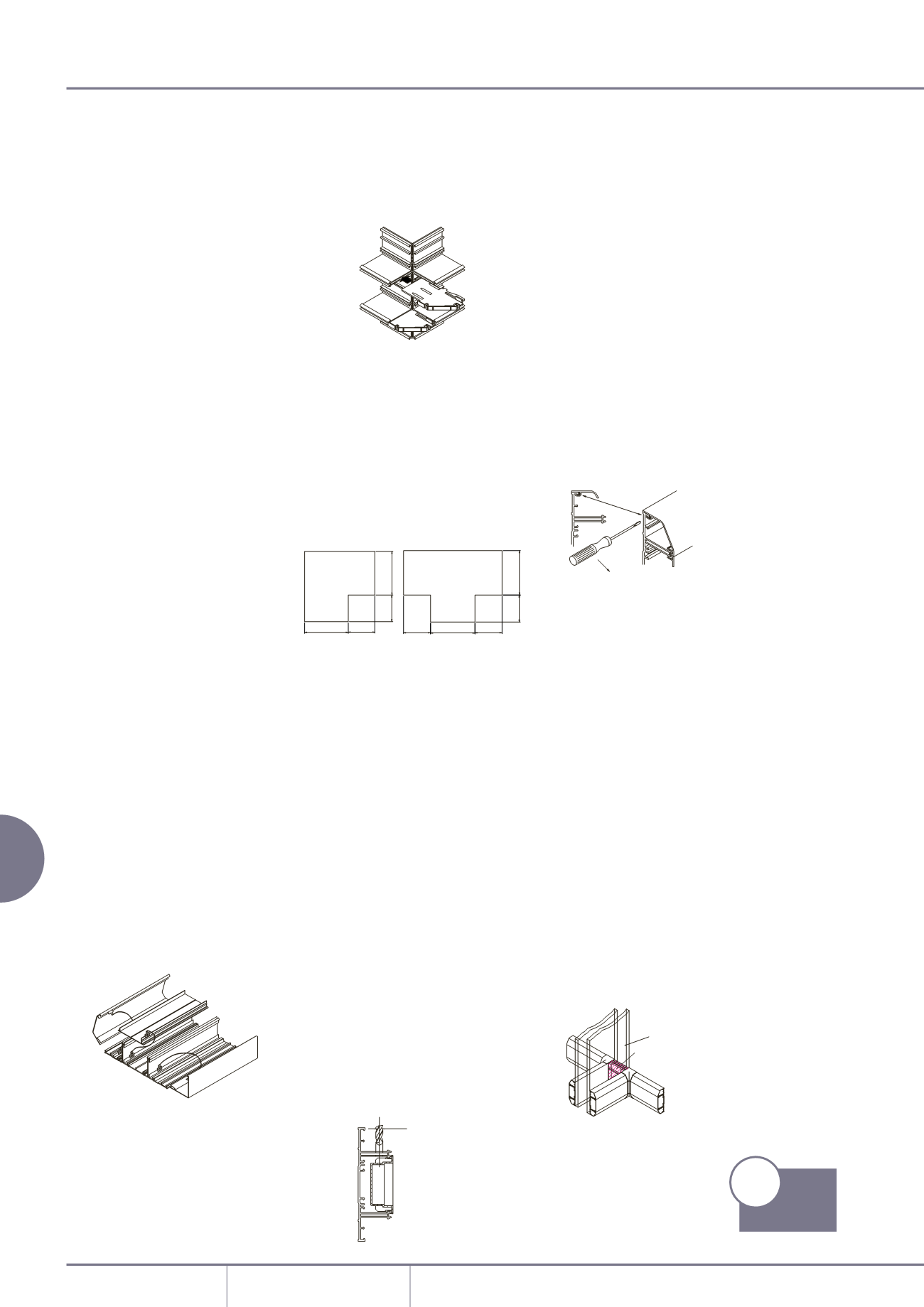

Fitting

• Secure trunking base every 750mm.

• Secure using No 8 round head screws

and washers using the grooves in the

outer compartments of the base to

facilitate drilling 6mm holes.

• Avoid over-tightening to permit

thermal movement.

• The use of plastic caps over screw

heads is recommended to protect

installed cables.

• To cut the trunking, use a fine tooth

blade (32/36tpi) or, preferably,a

circular saw with a 350mm diameter

fine tungsten blade (90/108tpi).

This will produce an edge requiring

minimal de-burring.

• Consecutive lengths of base are

aligned and butt jointed together.

Earthing

• Clean protective coating from base,

covers and metallic fittings and then

earth bond.

• Incoming earth connection is made

using LTB1 bonding assembly

installed in the earth channel of the

base.

• Bonding base to base: in final ring or

radial 32Amp circuits, bonding strap

LBS1 can be used.

• Bonding covers and end caps to base:

use bonding strap LBS2.

Single lengths

Where it is required to fit a single

length of trunking (under 3 metres)

between two inside walls and no

accessory box is fitted, it is advisable to

install a coupler in the centre of the run

to facilitate the removal of the cover.

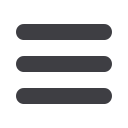

Joints and bends

• Moulded from colour-matching

polycarbonate.

• External bends: base should be cut

square at the corner and the internal

segregator inserted into the web of

each base.

• Internal bends: base must be mitred

45° to ensure total enclosure of

trunking, including any internal fitted

segregator.

• Flat angles, tees and crossovers are

prefabricated aluminium.

• External moulded fittings overlap the

joints by up to 10mm to cover cutting

inaccuracies.

Bend radius control

For data bend radius control fittings for

XL, please contact the Technical Team

on +44 (0)1424 856688.

Accessory boxes

• If accessory box in main compartment

is supplied from an outer

compartment, drill the main web

adjacent to the box position.

• Remove the appropriate knock out

and clip the box into the trunking

base.

• For boxes in the same compartment

as the supply, remove the appropriate

box knock-outs and clip the box into

trunking base.

• When boxes are installed

consecutively, a 14mm minimum

space is required to cover the space

between the boxes (use PVC-U

ES1WH or use section of aluminium

cover)

• Part M box assemblies with

contrasting coloured faceplates are

available to meet the requirements

of DDA regulations for Visual

Impairment.

Covers

The covers have been designed to

remain in position irrespective of

impact during normal conditions,

minor undulations of the mounting

surface, and to limit unauthorised

removal.

Covers – fitting

Covers are clipped into place from the

front. If accessory boxes are installed,

the LTL1 covers are butt-joined to the

edge of the box (ESSB1 and 2 only) and

the cut edges of lids are subsequently

concealed by the accessory. For fittings,

a gap of 30mm is left between the two

cover ends to permit the fitting to clip

to the base.

Covers – removal

To remove a cover, first detach a

coupler, internal or external bend

component to gain access. The main

cover can then be gently eased off

the base. To remove the outer cover,

firstly ease from the base by inserting

the blade of a terminal screwdriver

between the captive legs of the cover

and the base and then peel off.

Screening

Aluminium containment will protect

all internal circuits from external

electromagnetic interference. For

internal segregation and screening, use

a screened dividing fillet.

Method of continuation through

a partition wall

Continue the main lateral run of base

through the partition wall with short

lengths of cover fitted where the

trunking passes through the partition.

The partition wall trunking is then

butted up to the main run and the

joint covered by an Internal bend. (as

shown below)

DRILL HOLE OF

SUITABLE SIZE

INSERT SCREWDRIVER

INTO SHADED AREA

LEVER OUT

PARTITION WALL

COVERS TO BE FITTED

BEFORE BASE IS INSTALLED

XL trunking aluminium

X

100mm

X

100mm

100mm

X

100mm

X

100mm

X

100mm

X

100mm

100mm

X

100mm

X

100mm

220mm

308mm

220mm

308mm

Template dimensions for

Flat angle and Tee

p170

Product

Information