Tel

+44 (0)1424 856600

Fax

+44 (0)1424 856611

Technical Hotline

+44 (0)1424 856688

TECHNICAL INFORMATION

Technical information

292 |

Aluminium trunking systems

Covers

Covers are designed to limit

unauthorised removal and to remain

in position during normal conditions

irrespective of impact and minor

undulations of the mounting surface.

Covers – fitting

Covers are clipped into place from

front. If accessory boxes are installed,

the LTL1 cover is butt-joined to the

edge of the box. Cut edges of the cover

are subsequently concealed by the

accessory. For fittings, a gap of 25mm

is left between the two cover ends to

permit the fitting to clip to base.

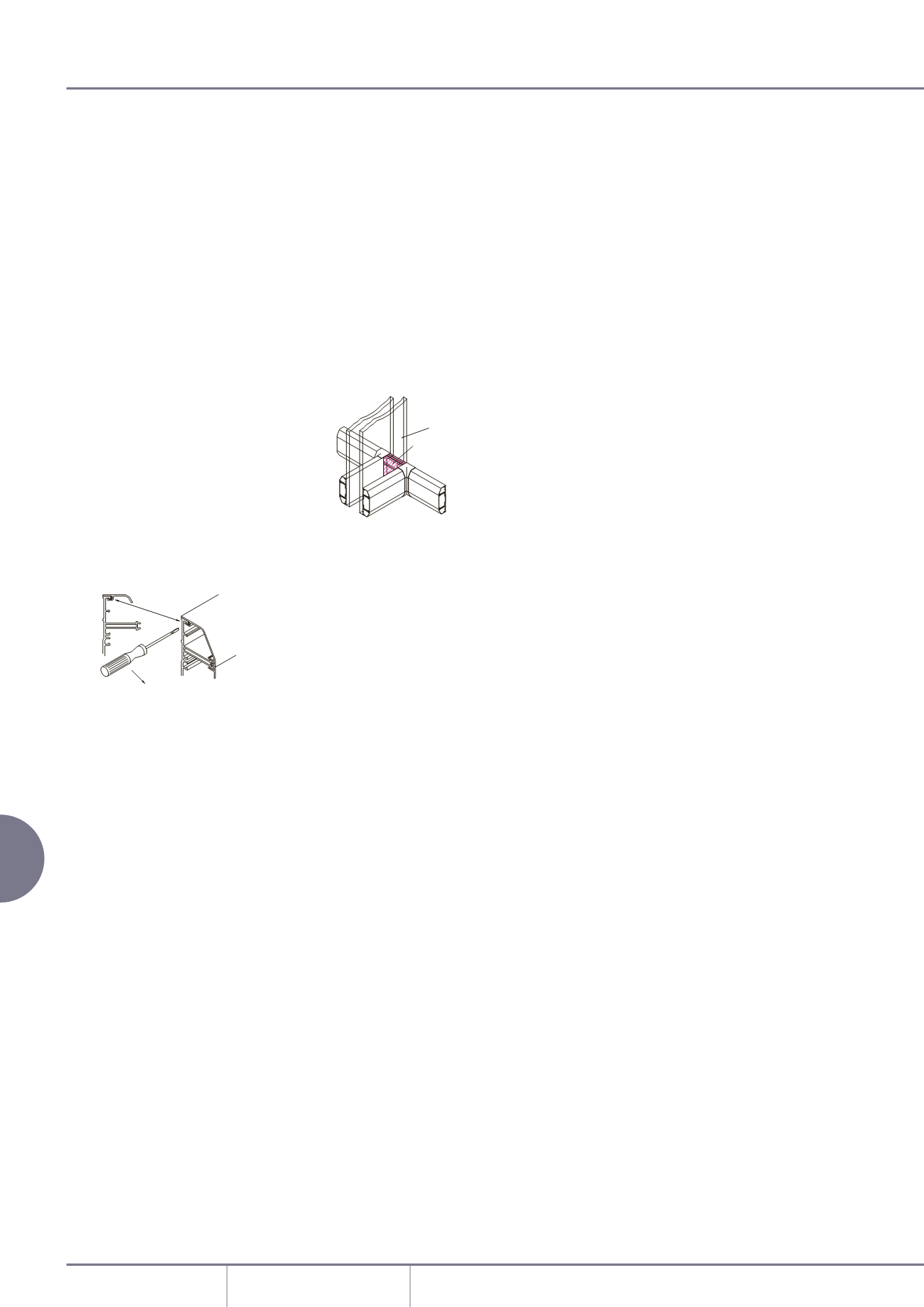

Covers – removal

To remove a cover, first detach a

coupler, internal or external bend

component to gain access. The main

cover can then be gently eased off

the base. To remove the outer cover,

firstly ease from the base by inserting

the blade of a terminal screwdriver

between the captive legs of the cover

and the base and then ease away from

the base.

INSERT SCREWDRIVER

INTO SHADED AREA

LEVER OUT

PARTITION WALL

COVERS TO BE FITTED

BEFORE BASE IS INSTALLED

Screening

Aluminium containment will protect

all internal circuits from external

electromagnetic interference. For

internal segregation and screening, use

a screened dividing fillet.

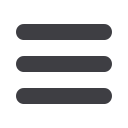

Method of continuation through

a partition wall

Continue the main lateral run of base

through the partition wall. Fit short

lengths of cover where the trunking

passes through the partition. The

partition wall trunking is then butted

up to the main run and the joint

covered by an internal bend fitting.