TECHNICAL INFORMATION

Technical information

Material

Aluminium trunking is manufactured

from high precision extruded

aluminium with a powder coat finish.

White RAL 9016

Silver Grey RAL 9006

Accessory boxes are supplied in PVC-U

or polycarbonate both of which are

100% recyclable.

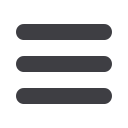

Installation

Positioning

Suitable for dado and skirting installation.

When used as a skirting system, sufficient

clearance should be allowed between

the floor covering and the profile fittings

that clip over the cover i.e. 5mm + floor

covering is recommended.

Fitting

• Secure trunking base every 750mm.

• Secure using No 8 round head screws

and washers using the grooves in the

outer compartments of the base to

facilitate drilling Ø6mm holes.

• Avoid over-tightening to permit

thermal movement.

• The use of plastic caps over screw

heads is recommended to protect

installed cables.

• To cut the trunking, use a fine tooth

blade (32/36tpi) or, preferably,a

circular saw with a 350mm diameter

fine tungsten blade (90/108tpi).

This will produce an edge requiring

minimal de-burring.

• Consecutive lengths of base are

aligned and butt jointed together.

Earthing

• Clean protective coating from base,

covers and metallic fittings and then

earth bond.

• Incoming earth connection is made

using LTB1 bonding assembly installed

in the earth channel of the base.

• Bonding base to base: in final ring or

radial 32Amp circuits, bonding strap

LBS1 can be used.

• Bonding covers and end caps to

base: use bonding strap LBS2.

Single lengths

Where it is required to fit a single

length of trunking (under 3 metres)

between two inside walls and no

accessory box is fitted, it is advisable to

install a coupler in the centre of the run

to facilitate the removal of the cover.

Joints and bends

• Moulded from colour matching

polycarbonate.

• Internal and external bends must

be mitred at 45° to ensure total

enclosure and segregation of

trunking compartments, including

any internal fitted segregator.

• Straight lengths should be butt

jointed together.

• Flat angles and tees are prefabricated

in aluminium.

• Cutting of base and covers is not

critical as external moulded clip-on

fittings cover the joint and overlap

covers by 10mm each side to cover

minor inaccuracies.

MIN

90mm

5mm +

FLOOR

COVERING

STERLING COMPACT

AND PROFILE

DRILL HOLE OF

SUITABLE SIZE

Bend radius control

Contact the Technical Team on

+44 (0)1424 856688

Accessory boxes

• For mounting an accessory box in the

alternative compartment to supply,

drill the main web adjacent to the

box position.

• Remove the appropriate knock out

and clip the box into the trunking

base.

• For boxes in the same compartment

as the supply, remove the

appropriate box knock-outs and clip

the box into trunking base.

• When boxes are installed

consecutively, a 14mm wide spacer

(ES1) is required to cover the space

between the boxes.

• Part M box assemblies with

contrasting coloured faceplates are

available to meet the requirements

of DDA regulations for Visual

Impairment.

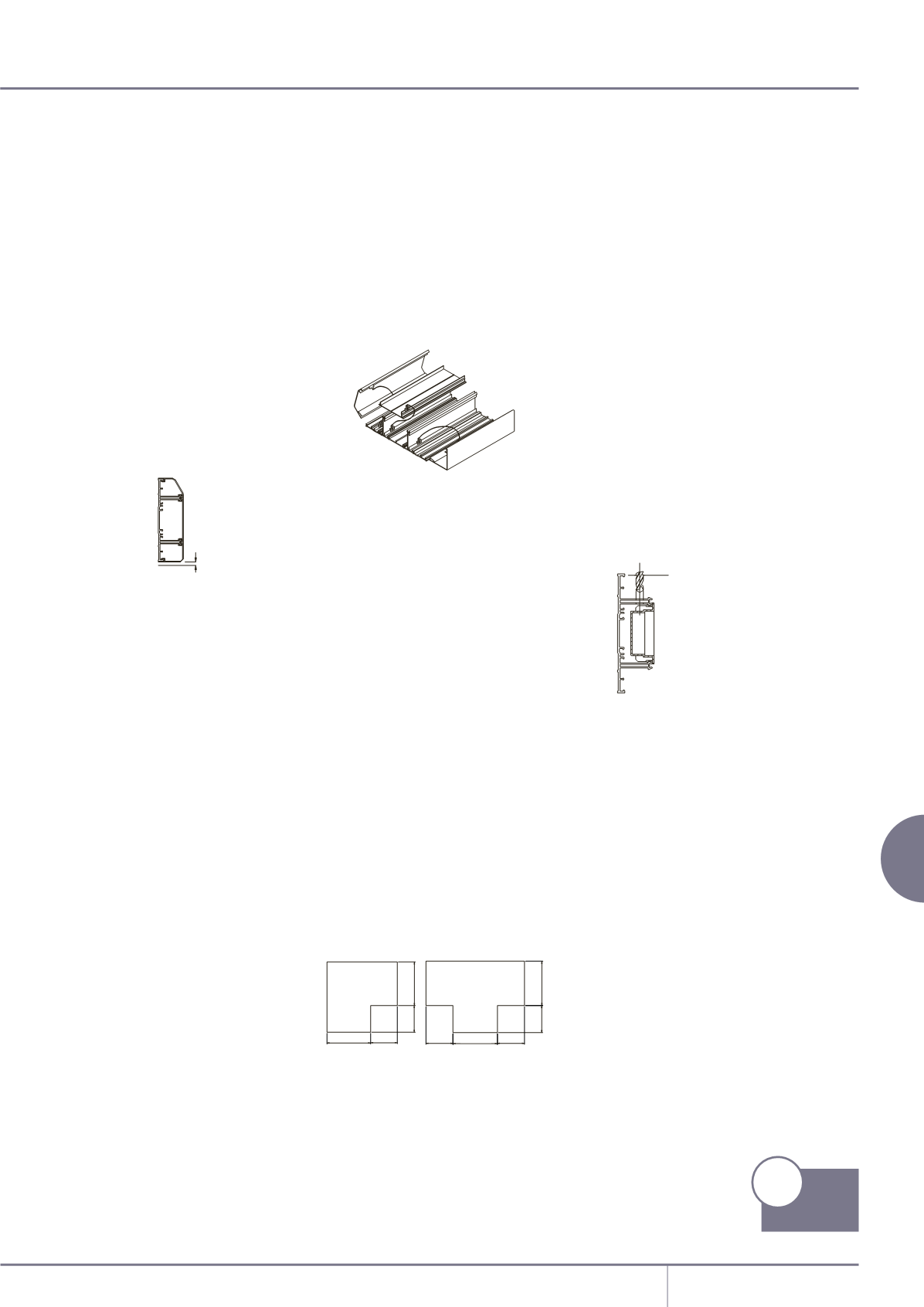

Sterling Profile aluminium

X

100mm

X

100mm

100mm

X

100mm

X

100mm

167mm

167mm

X

100mm

X

100mm

100mm

X

100mm

X

100mm

167mm

167mm

p166

Product

Information

Aluminium trunking systems

| 291