TECHNICAL INFORMATION

Technical information

Material

Aluminium trunking is manufactured

from high precision extruded

aluminium with a powder coat finish.

White RAL 9016

Silver Grey RAL 9006

Accessory boxes are supplied in PVC-U

or polycarbonate both of which are

100% recyclable.

Installation

Positioning

Bench and desk installations: a single

run can be fitted to rear of furniture

or, if run down centre line, two units

can be joined back to back presenting

accessories on both sides.

Fitting

• Secure trunking base in one plane

only every 500mm by drilling

alternative Ø6mm holes either side of

divider nib.

• Secure using No 8 round head screws

and washers. Avoid over-tightening

to permit thermal movement.

• The use of plastic caps over screw

heads is recommended to protect

installed cables.

• To cut the trunking, use a fine tooth

blade (32/36tpi) or, preferably, a

circular saw with a 350mm fine

tungsten blade (90/108tpi). This will

produce an edge requiring minimal

de-burring.

• Consecutive lengths of base are

aligned and butt jointed together.

Earthing

• Base, covers and metallic fittings to

be cleaned of protective and powder

coatings and earth bonded.

• Incoming earth connection is made

using LTB1 bonding assembly

installed in the earth channel of the

base.

• Bonding base to base: in final ring or

radial 32Amp circuits, bonding strap

LBS1 can be used. Bonding cover to

base use LBS2

Joints and bends

• Base joints should be butt jointed

together.

• Internal and external bends are

prefabricated in aluminium, aligned

and butt jointed together so cutting

of base and covers has to be very

accurate to produce a good finish.

Bend radius control

Contact the Technical Team on

+44 (0)1424 856688

Accessory boxes

• Remove the appropriate box

knockout that align with segregated

compartment containing supply

cable and clip the box into the

trunking base.

• When boxes are installed

consecutively, a 14mm wide spacer

(ES1) is required to cover the space

between the boxes.

• Part M box assemblies with

contrasting coloured faceplates are

available to meet the requirements

of DDA regulations for Visual

Impairment.

Covers

Covers are designed to limit

unauthorised removal and to remain

in position during normal conditions

irrespective of impact and minor

undulations of the mounting surface.

Covers – fitting

Covers are clipped into place from

front. If accessory boxes are installed,

the LTL1 cover is butt-joined to the

edge of the box (ESSB1/2 only). Cut

edges of the cover are concealed by

the accessory. Adjoining covers are

butt-jointed.

Covers – removal

To remove a cover, first detach an

accessory to gain access. The main

cover can then be gently eased off the

base.

Screening

Aluminium containment protects

internal circuits from external

electromagnetic interference. For

internal segregation and screening, use

a screened dividing fillet.

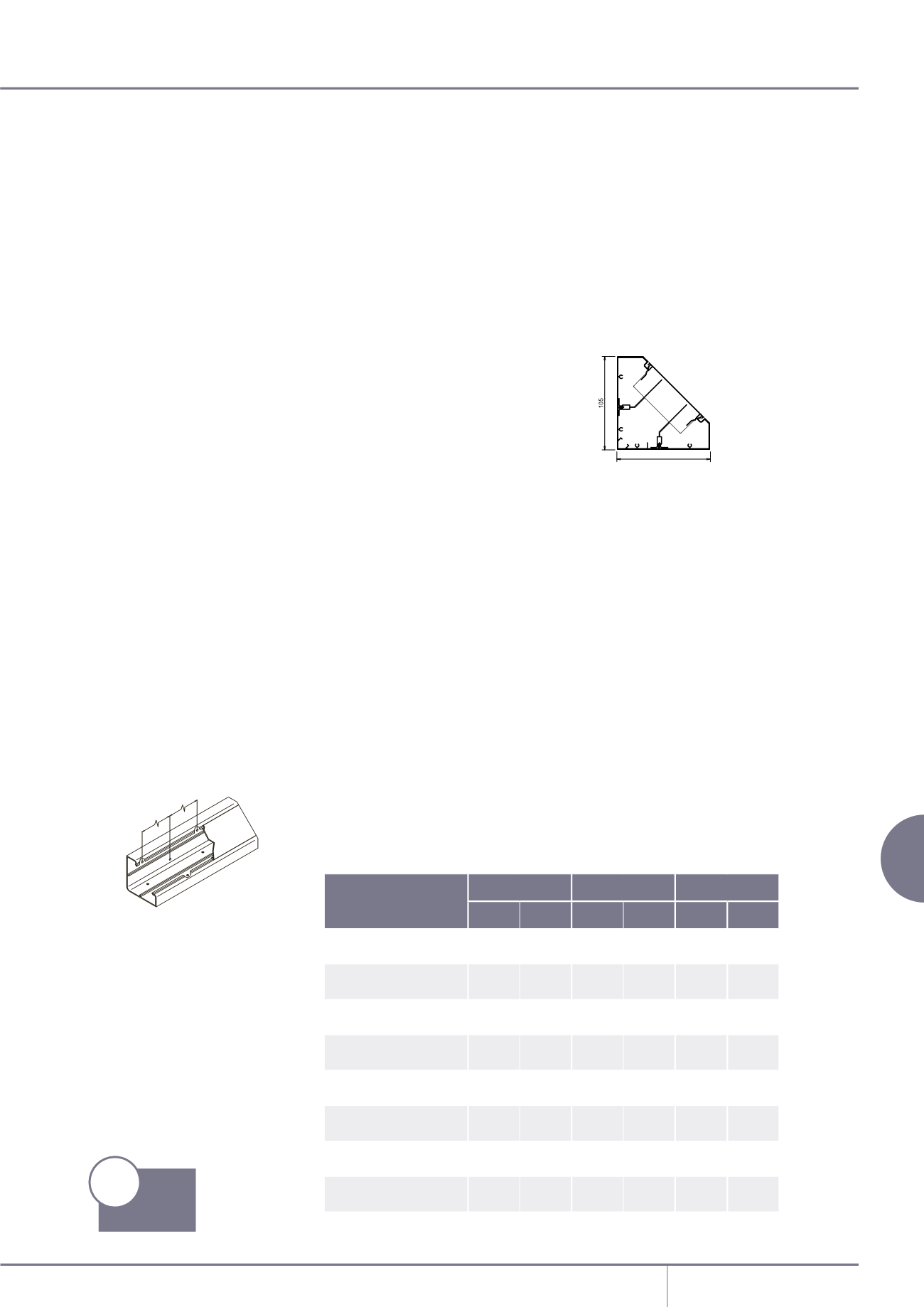

Dimensions

Bench trunking – with box

1 = 1345mm

2

total area

1 = 605mm

2

45% space factor

2 = 2188mm

2

total area

2 = 984mm

2

45% space factor

3 = 1345mm

2

total area

3 = 605mm

2

45% space factor

Bench trunking – No box

1 = 1842mm

2

total area

1 = 828mm

2

45% space factor

2 = 3342mm

2

total area

2 = 1504mm

2

45% space factor

3 = 1842mm

2

total area

3 = 828mm

2

45% space factor

Cable capacities

• All calculations allow for

a 45% space factor.

As there can be differences between

data cable sizes, Marshall-Tufflex

recommend that cable dimensions

are confirmedwith themanufacturing

company.

Cable capacity chart

Compartment 1 Compartment 2 Compartment 3

No box With box No box With box No box With box

PVC power cable

1.5mm² stranded copper

104

76

188

123

104

76

PVC power cable

2.5mm² stranded copper

70

51

126

83

70

51

PVC power cable

4.0mm² stranded copper

50

36

91

59

50

36

Data cable: Ø5.5mm

35

25

63

41

35

25

Data cable: Ø6.0mm

29

21

53

35

29

21

Data cable: Ø6.5mm

26

19

47

31

26

19

Data cable: Ø7.0mm

22

16

39

26

22

16

Data cable: Ø8.4mm

15

11

27

18

15

11

Only for straight runs. If bends are required please contact the Technical Team on +44 (0)1424 856688.

500mm

500mm

OPTION 1; BACK ONLY

OPTION 2; BASE ONLY

Bench trunking aluminium

p181

Product

Information

C. &C.MarshallLtd.

3

1

2

Aluminium trunking systems

| 289