2010

CA08103002Z-EN

www.eaton.comFrequency inverters

General information about engineering information

10/25

General informationaboutengineering information

Modulation

The IGBTs in the inverter of the

M-Max™ and H-Max™ frequency

inverters are controlled with

sinusoidal pulse-width modulation

(

PWM). Two control methods are

possible:

•

Voltage/frequency (U/f) control,

•

Sensorless vector control (speed

control).

Voltage/frequency control

is the

best-known and most commonly used

method. A simple characteristic curve

(

linear or square) defines the motor’s

rotating field frequency and the

corresponding three-phase line-to-

line voltage of the motor is selected

so that the motor is neither over

magnetized nor under magnetized.

The main fields of application of U/f

control are:

•

Pump and fan drives,

•

Horizontal conveying and transpor-

tation systems,

•

Drives with several motors (parallel

operation of several motors at the

output of a frequency inverter).

In

sensorless vector control

the

magnetic fields of the stator and rotor

windings are aligned so as to oppose

each other. With asynchronous

motors the magnetic flux in the rotor

must be described in an electronic

model of the motor. This requires the

physical parameters on the motor’s

rating plate to be entered.

In vector operation the frequency

inverter can control only one motor.

A parallel operation of several motors

is not possible here. The exact

calculation of the phase voltages at

the frequency inverter’s output,

however, improves the motor’s

operational behavior. The motor also

heats up less in the lower speed range.

The field-oriented vector control

results in a significant improvement

in the drive dynamics as well as

optimizing performance; it also

increases the range of possible

applications.

The main applications of sensorless

vector control are:

•

Material processing machines,

•

compressors,

•

Heavy starting duty (extruders,

agitators, mixers),

•

Horizontal conveying equipment

(

cranes, elevators).

Explanation:

EMC = electromagnetic

compatibility

IGBT = insulated-gate bipolar

transistor

PDS = power drive system

RCD = residual-current device

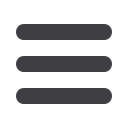

①

Stator winding

②

Air gap

③

Transformed rotor winding

Simplified equivalent circuit diagram with associated current vectors

R

1

a

c b

X'

2

X

1

i

1

i

w

u

1

X

h

i

m

R'

2

s

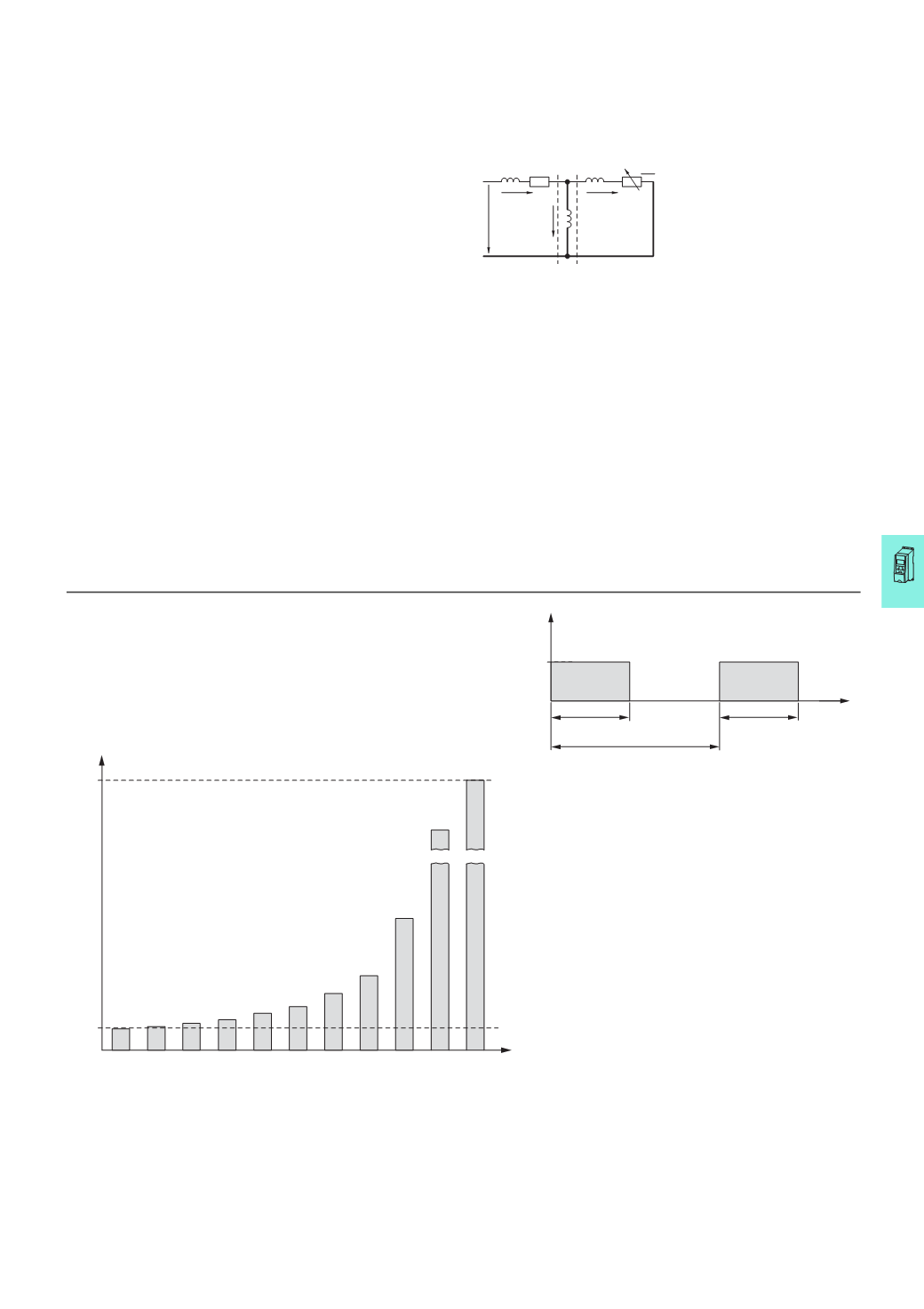

Technical information about the braking resistors

:

The stated ratings P

DB

of the braking resistors apply to continuous operation.

In short-time operation these values can be increased through multiplication with the

type-specific power factor according to the following formula:

P

max

≤ (P

DB

× 100 %) ÷ DF [%]

P

max

= max. pulse rating

P

DB

= continuous rating at a duty factor of 100 %

DF = duty factor

t

c

= cycle time (max. 120 seconds)

The duty factor is given in percent (%) and is calculated with the following formula:

DF [%] = (DF × 100 %) ÷ t

c

P

DB

ED

P

max

1

2

6

1.1 1.25 1.4 1.7

2.6

3.4

10

20

100 90 80 70 60 50 40 30 20 10 5

ED [%]

P

DB

t

[

s]

ED

t

C

(

F

120

s)