D-18

Additional information

Designing horizontal busbars

Linergy BS

Electrical characteristics

Permissible current and selection of horizontal busbar

The goal is to optimise busbar size according to the installation and operating

criteria.

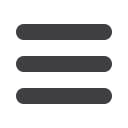

Up to 1600 A

Linergy BS bars, 5 mm thick

Type of bars

Permissible current (A)

Ambient temperature around the switchboard

25 °C

30 °C

35 °C

40 °C

45 °C

50 °C

Size per phase

IP

y

31 IP > 31 IP

y

31 IP > 31 IP

y

31 IP > 31 IP

y

31 IP > 31 IP

y

31 IP > 31 IP

y

31 IP > 31

1 Linergy BS bar, 60 x 5

890

840

850

790

800

750

760

700

710

650

660

bb

1 Linergy BS bar, 80 x 5

1130 1050 1080 990

1000 900

970

870

910

810

860

bb

2 Linergy BS bars, 60 x 5

1580 1420 1500 1350 1400 1250 1350 1180 1260 1090 1180

bb

2 Linergy BS bars, 80 x 5

2010 1820 1920 1720 1800 1600 1720 1510 1610 1390 1510

bb

bb

Connection impossible due to the operating-temperature limits of the devices installed in the switchboard.

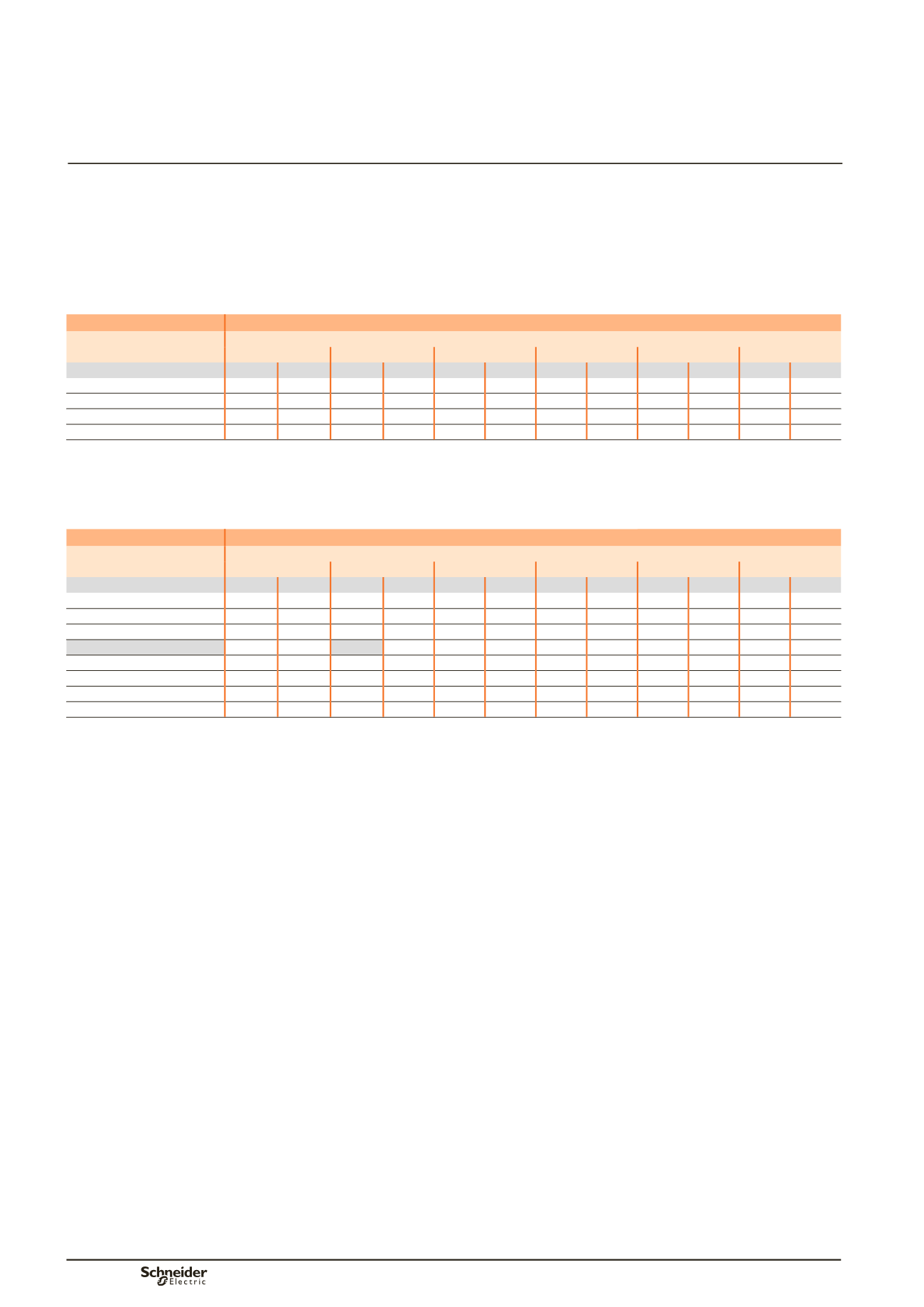

Up to 3200 A

Linergy BS bars, 10 mm thick

Type of bars

Permissible current (A)

Ambient temperature around the switchboard

25 °C

30 °C

35 °C

40 °C

45 °C

50 °C

Size per phase

IP

y

31 IP > 31 IP

y

31 IP > 31 IP

y

31 IP > 31 IP

y

31 IP > 31 IP

y

31 IP > 31 IP

y

31 IP > 31

1 Linergy BS bar, 50 x 10

1330 1220 1260 1160 1200 1080 1130 1010 1060 940

990

bb

1 Linergy BS bar, 60 x 10

1550 1400 1470 1320 1400 1250 1320 1160 1240 1070 1160

bb

1 Linergy BS bar, 80 x 10

1990 1800 1890 1700 1800 1600 1700 1500 1600 1390 1500

bb

2 Linergy BS bars, 50 x 10

2270 2090 2160 1980 2050 1850 1930 1740 1810 1610 1690

bb

2 Linergy BS bars, 60 x 10

2550 2270 2420 2140 2300 2000 2170 1870 2030 1720 1900

bb

2 Linergy BS bars, 80 x 10

3110 2820 2970 2660 2820 2500 2660 2330 2500 2160 2330

bb

2 Linergy BS bars, 100 x 10

3650 3280 3490 3100 3300 2900 3130 2720 2950 2510 2750

bb

2 Linergy BS bars, 120 x 10

4160 3760 3960 3550 3760 3340 3560 3100 3340 2880 3120

b

bb

Connection impossible due to the operating-temperature limits of the devices installed in the switchboard.

Example:

Two 50 x 10 mm bars can be used for a 2160 A current with an IP

y

31 and an

ambient temperature of 30 °C around the switchboard.

Where possible, use of 10 mm bars is worthwhile in terms of the In/Isc:

bb

gain in time during switchboard mounting given, where applicable, the lesser

number of bars installed

bb

for short-circuits, the rigidity of the bars means fewer busbar supports.

Recommendation:

Use 5 mm bars for In

y

1600 A and low Icw values (40 kA rms).

Use 10 mm bars for In > 1600 A and medium to high Icw values (> 40 kA rms).

Note:

the values indicated above have been validated for Prisma P switchboards.