D-16

Additional information

Designing Prisma P

power circuits

Presentation and approach

Electrical characteristics

Designing the PE protective

conductor

The protective conductor must be sufficiently sized and securely installed in the

switchboard to accept the thermal and electrodynamic constraints of the fault

current.

It must be connected to the exposed conductive parts of the switchboard.

It must be accessible to enable connections both in the factory and on site.

Optimised calculation method

Use the calculation equation indicated in standard IEC 60439-1 and 2:

S

PE

= l

2

t

k

b

SPE: cross-sectional area of the PE in mm²

b

I: value of the phase-to-earth fault current = 60 % of the value of the

phasetophase

b

fault current (IEC 60439-1 §8.2.4.2)

b

t: time the fault current flows in seconds

b

k: coefficient that depends on the type of metal, k = 143 for a copper

conductor with PVC insulation.

Example:

v

Isc = 36 kA rms C the value of the phase-to-earth fault current = 60 % of the value

v

of the phase-to-phase fault current (standard IEC 61439-1 and 2 § 8.4.3.2.3 and

10.11.5.6), i.e.: 36 x 0.6 = 21.6 kA

v

maximum time delay for the control unit: 0,5 s

v

k = 143 for copper conductors with PVC insulation.

The calculation is therefore:

v

v

S

PE

= 21600

2

x 0,5 = 106,8 mm

2

143

The PE conductor must therefore be a 25 x 5 mm bar (= 125 mm

2

).

Simplified method (based on the equation above)

Use the table below to determine the size of the PE conductor as a function ofdevice

short-circuit current Isc.

Size of PE conductor

All Schneider Electric devices

Isc

y

40 kA

1Linergy BS bar, 25 x 5 mm

Isc

y

65 kA

1Linergy BS bar, 50 x 5 mm Linergy LGY 630 -

04502

Isc > 65 kAmais < 80 kA

1Linergy BS bar, 50 x 5 mm Linergy LGY 800 -

04503

Isc = 100 kA

1Linergy BS bar, 50 x 5 mm Linergy LGY 1000 -

04505

DD381471.eps

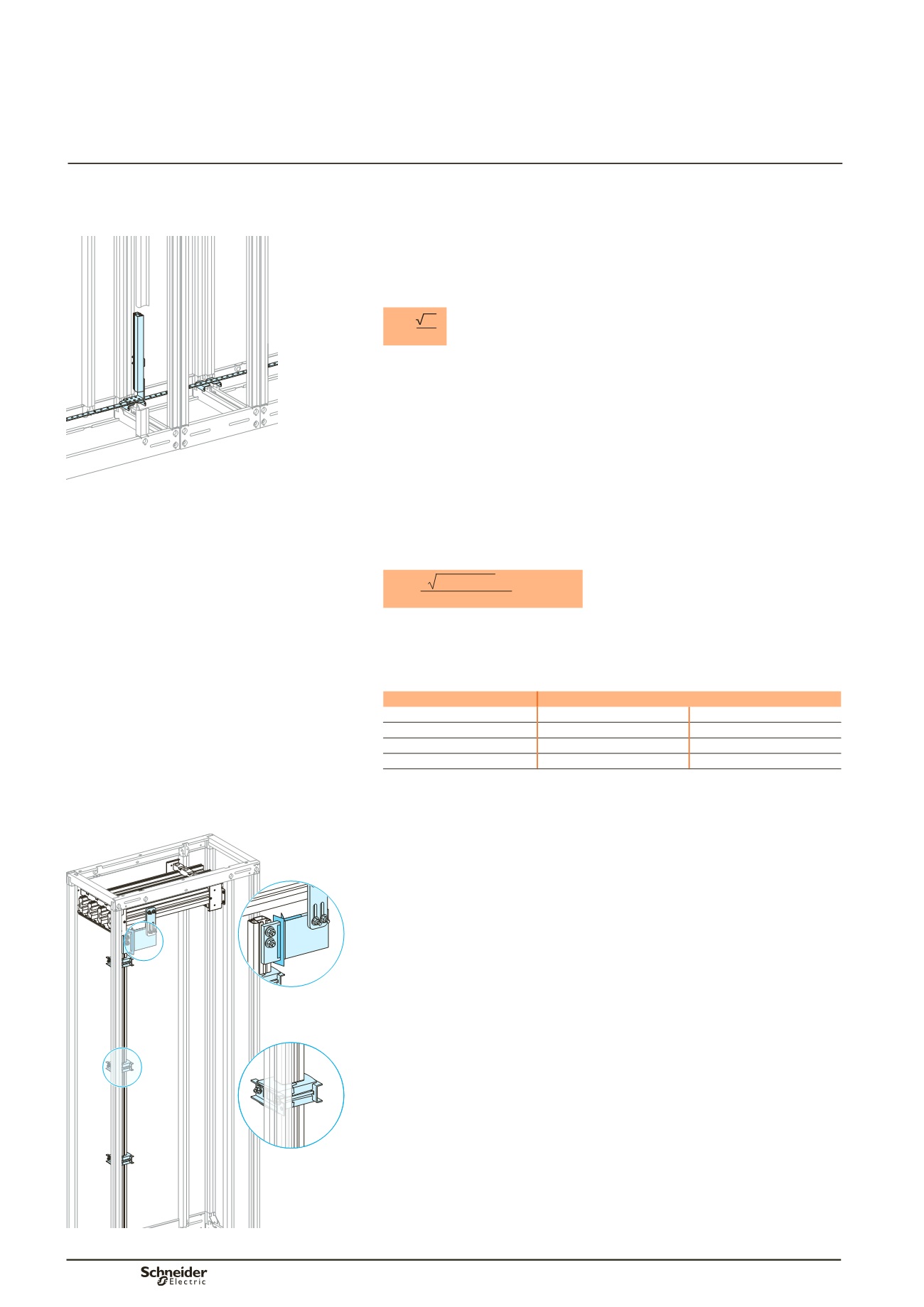

Implementing the PEN protective

conductor

The size of the PEN is determined in the same manner as a neutral conductor, i.e.:

bb

for copper single-phase circuits or sized

y

16mm², it must be the same size as the

phase conductors

bb

for copper three-phase circuits sized > 16 mm², it can be:

vv

the same size as the phase conductors

vv

smaller on the condition that:

- the current likely to flow in the neutral during normal operation is less than the

permissible current for the conductor

- the power rating of single-phase loads does not exceed 10 % of the total rating.

The conductor must be accessible to enable connections both in the factory and

on site, as well as checks on the tightness of connections.

DD384616.eps

Installation du conducteur de protection PEN

According to standard IEC 61439-1 and 2, the practical guidelines for implementing

the PEN are the following:

bb

at the entry to the assembly, the PEN connection must be next to the phase

connections

bb

within the assembly, the PEN does not need to be insulated from the exposed

conductive parts (except on sites where there is a risk of fire or explosion)

bb

the size of the conductor must be at least equal to that of the neutral

bb

the size must remain constant throughout the main busbars

bb

the change from a TNC to a TNS system must take place at a single point in the

switchboard, via a marked neutral-disconnection bar that is accessible and can be

dismantled to facilitate the impedance measurement of the fault loop

bb

after the TNS creation point, it is forbidden to recreate a TNC system.

The PE and the neutral must meet their specific requirements.

Linergy LGY PEN kit

See page B-49.