D-102

Additional information

Maintenance

Preventive maintenance

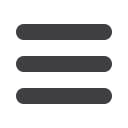

DD382159.eps

General inspection

Visual checks and general cleaning of the cubicles

bb

Check the lack of humidity and foreign bodies inside and outside the switchboard.

bb

Examine the outer finish. If necessary, touch up any paint scratches and replace

any damaged or rusted parts.

bb

Clean the switchboard, preferably with a vacuum cleaner.

bb

If necessary, clean the ventilation system and change the filters.

Visual check of busbars

bb

Connections do not need to be tightened as they was already be tightened to the

tightening torque in worshop and the use of a contact washer compensates for

possible creeps due to overheating. The presence of vernish guaranteeing correct

tightening torque, is intact.

bb

The control of busbars connections and outgoing cables connections can be

carried when disassembling the protection (out of supply) or if a hot point is detected

(infrared control or thermal sensors). A hot point materialises by a change in the

copper colour.

bb

In case of hot point see "Corrective maintenance".

bb

Check the condition of insulating busbars supports.

Cleaning of panel ventilation filters

Standard or fine filters

bb

Wash with water (preferably using a high-quality detergent).

bb

It is also possible to remove the dust by tapping, vacuuming or blowing with

compressed air.

bb

If there is any oil or grease, change the filter.

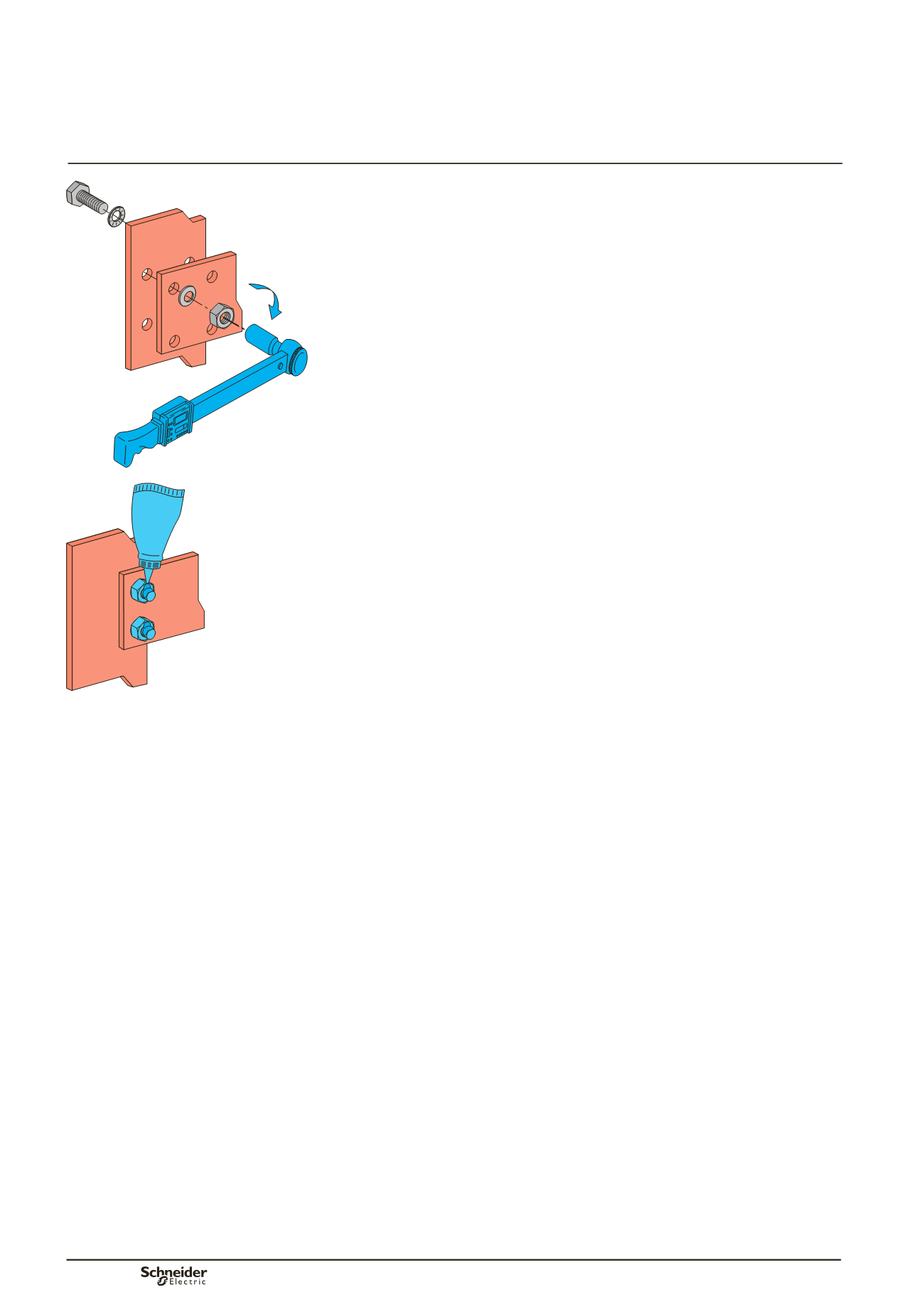

E20488.eps