D-93

Additional information

Practical information

masterpact II

MERLINGERIN

NX 08HA10

Ui 1000VUimp 12kV

Ue

690

(V)

50kA/1s

IEC 947-2 50/60Hz

EN 60947-2

UTEVDEBSCEIUNEASNBMA

masterpact II

MERLINGERIN

NX 08HA10

Ui 1000VUimp 12kV

Ue

690

(V)

50kA/1s

IEC 947-2 50/60Hz

EN 60947-2

UTEVDEBSCEIUNEASNBMA

DD383914.eps

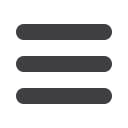

Final unpacking of the equipment will preferably take place just before the

switchboard is installed, as close as possible to its final installation location.

As a general guideline, the weight of an average 3200 A cubicle is around 400 kg.

Cubicles should always be handled in the

upright position

with care, if possible

by 2 persons

. There is a risk of overtipping the cubicle due to the high position of

the centre of gravity.

When moving the cubicles, always turn slowly and smoothly, avoiding all bumps and

jerks. Enclosures moved using a forklift truck must be lifted carefully and held in

position or fastened to the forklift truck using slings during transport.

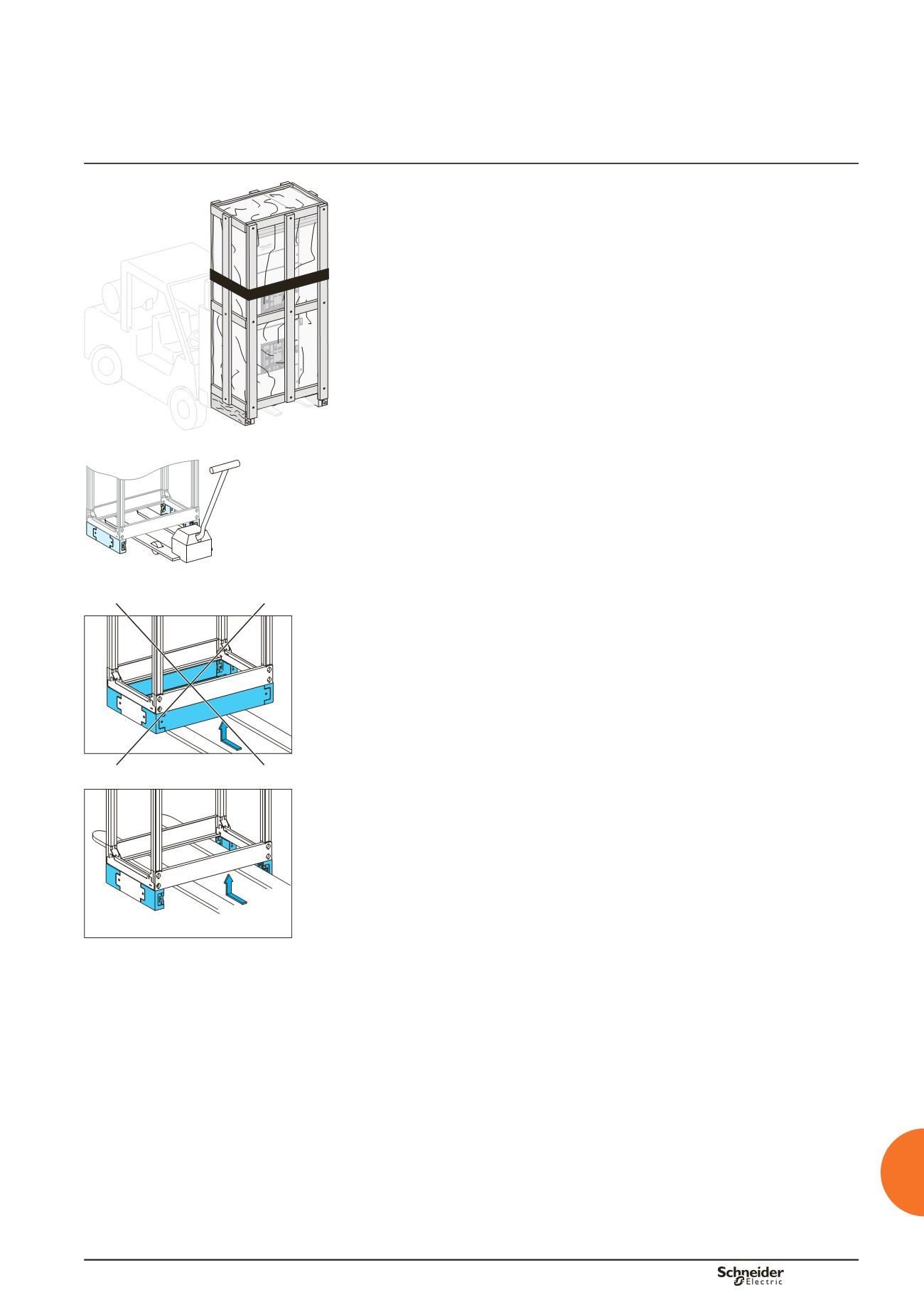

Handling by the bottom

Wooden beams (or framework stabilizers) are generally attached to the base of the

cubicle framework. This allows the cubicles to be moved using a pallet mover or

forklift truck.

d

The forks must be placed symmetrically with respect to the cubicle's axis so as

not to distort the base of the frame.

For cubicles fitted with a plinth, the front and rear base panels must be removed to

allow insertion of the pallet mover forks.

Cubicles must be lifted with care and held in place during transport by strapping

them onto the handling machine, especially for large distances or bumpy terrain.

For a Prisma P switchboard with a busbar compartment, lifting points must be shifted

towards the busbars.

Dd381333.eps

Framework stabiliser.

DD210573.eps

Cubicle with base.

Handling on the site