TECHNICAL INFORMATION

Technical information

PVC–U domestic and general trunking

| 305

Material

PVC-U is flame retardant and self-

extinguishing. It provides a 100%

recyclable material with good

sustainability.

Installation

Positioning

As feeder trunking.

Expansion/contraction

PVC-U expands and contracts at a

uniform rate of approx 5.25mm in

a 3 metre length for a temperature

change of 25°C. Therefore, a 3mm gap

between each length of trunking base

is recommended. Fittings allow for

thermal expansion of the covers.

Fitting

•

Mini trunking

• Secure trunking base at lease every

375mm by drilling 6mm holes.

• Fasten using roundhead screws.

•

Self-fixing mini trunking

• Remove protective film exposing

100-150mm of adhesive foam.

• Line up accurately and press firmly

into position.

• Repeat until base is installed.

• For long term performance we

recommend additional securing with

screws and washers.

Note:

the bond created by the tape can

be very strong. Maximum adhesion

occurs after 24 hours. Ensure surface is

dust-free, dry, clean and flat. Uneven

surface contact will reduce bonding

performance. Installation in cold

conditions below +5˚c may affect

adhesion.

Mini and Mini SF trunking

• Avoid over-tightening to permit

thermal movement.

• The use of plastic caps over screw

heads is recommended to protect

installed cables.

• To cut the trunking, use a fine-

toothed panel or power jig-saw.

• External profile fittings overlap joints

by up to 10mm to cover cutting

inaccuracies.

• A variable angle jig-saw or chop

saw is recommended for cutting 45°

mitres.

• End caps are secured using adhesive

solvent MSC.

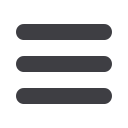

Joints and bends

• All fittings incorporate clip-on design.

• 3mm gap between trunking base

and bend or flat angle is

recommended.

• For internal bends and flat angles,

bases should be mitred 45˚.

• For external bends, bases should be

cut square to the corner.

• For tees, bases should be cut square

and butt up to each other.

• External clip on fittings overlap

trunking base by up to 10mm to

cover cutting inaccuracies.

• Secure end caps using solvent

adhesive MSC3.

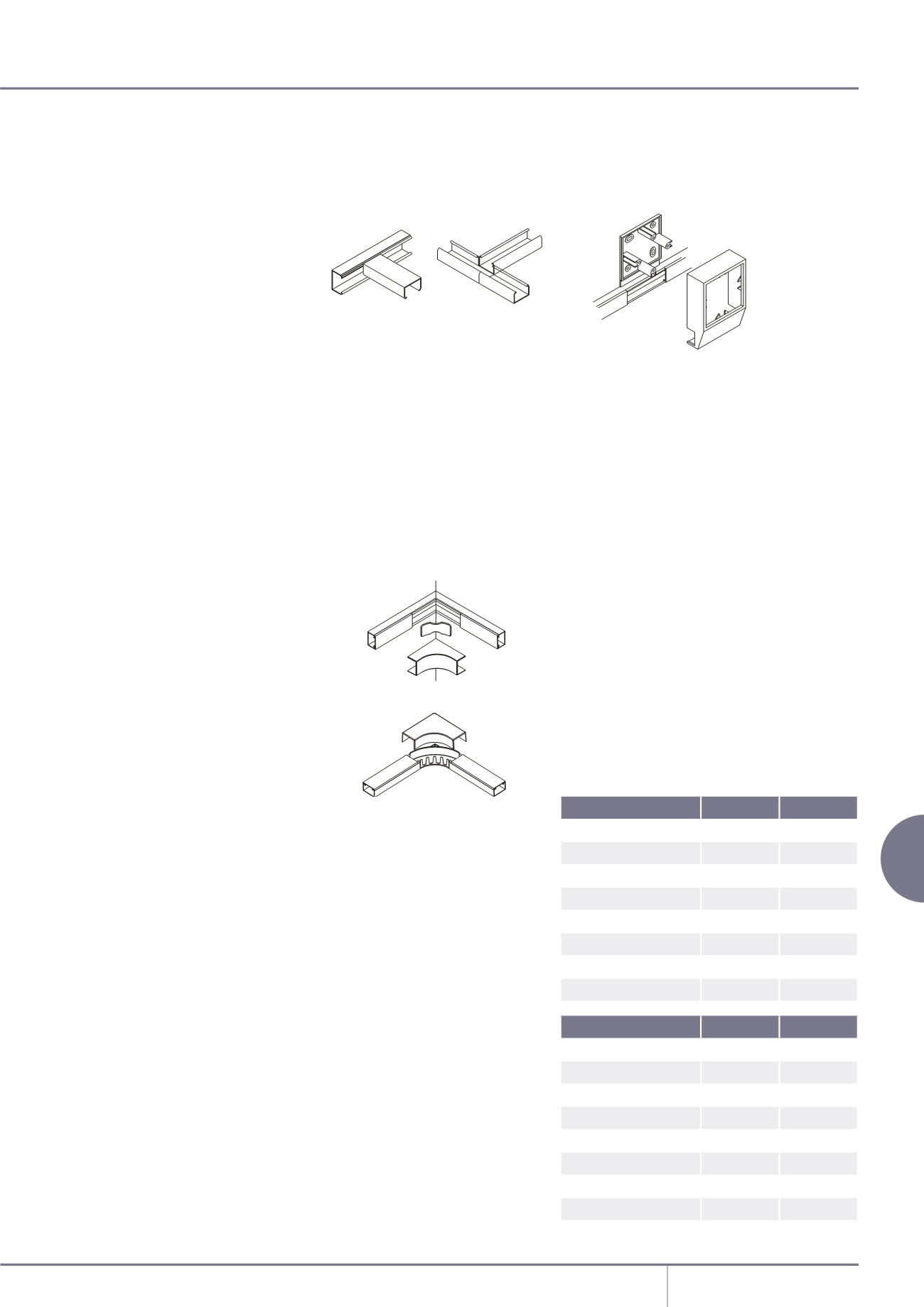

Bend radius control – MMT4 only

• For internal bends, base should be

mitred at 45°

• For external bends, base should be

cut square with the corner and the

radius control fitted.

• For flat angles and tees, allowance

should be made when cutting base,

for moulded components.

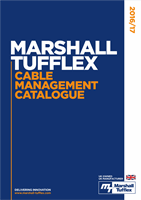

Accessory boxes

• Select appropriate surface box.

• Remove required knockout.

• Clean burrs from around aperture.

• Snap mini adaptor into position on

box and place in position.

• Ensure trunking seats securely into

adaptor.

• Secure box using diagonally opposite

fixing holes.

Shrouded entry boxes

• For use with MMT2 or MMT3 only.

• Fit back plate in position, secure

using diagonally opposite fixing

holes.

• Run mini base up to back plate (for

terminal accessory) or continue

through.

• Remove required knockout from

outer cover to fit mini trunking and fit

over base plate. Install wiring leaving

sufficient to wire accessory.

Conductor type

Size

Cable factor

Stranded PVC power

1.5mm

2

8.0

Stranded PVC power

2.5mm

2

11.9

Stranded PVC power

4.0mm

2

16.6

*Data cable

Ø5.5mm 23.8

*Data cable

Ø6.0mm 28.3

*Data cable

Ø6.5mm 33.2

*Data cable

Ø7.0mm 38.5

*Data cable

Ø8.4mm 55.4

Mini trunking

Size mm 45%capacity

MMT100

10 x 8

18.5mm

2

MMT0

16 x 10

42mm

2

MMT1

16 x 16

77.2mm

2

MMT2

25 x 16

119.7mm

2

MMT3

38 x 16

193mm

2

MMT4

38 x 25

342mm

2

MMT5

50 x 25

449mm

2

MMT6

38 x 38

501mm

2

MMT7

75 x 16

397mm

2

50mm radius internal

50mm radius

Cable capacities

• All calculations allow for a

45% space factor.

• Divide cable factor (1st table) into

capacity (2nd table) to ascertain

number of cables.

As there can be differences between data

cable sizes, Marshall-Tufflex recommend

that cable dimensions are confirmedwith

themanufacturing company.

Mini trunking

• Complete assembly is finally secured

together when the wired accessory is

screwed to accessory front plate.

• Fit mini trunking cover to base,

ensuring cover extends into

knockout.

Covers

Covers are designed to limit

unauthorised removal and to remain

in position during normal conditions

irrespective of impact and minor

undulations of the mounting surface.

Covers – fitting

Covers are clipped into place from

front.

Covers – removal

To remove a cover, first detach a

coupler or internal/external bend to

gain access. The cover can then be

gently eased off the base.