120

®

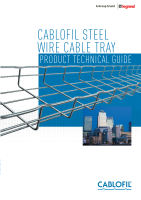

(vi) Spacing of supports

Services support installations are usually considered as

multi-span arrangements but it is important to recognise that

the loading capability of the system is not uniform from end-to-

end. The strength of the two end spans in any run is much lower

than that of intermediate spans, even when the ends are rigidly

fixed. In many situations the end spans will be more lightly loaded

anyway; if however they are not and the installation will be fully

loaded from end-to-end then it is recommended that the support

spacing of both end spans should be reduced to no more than

three quarters that of intermediate spans. However it is not a

mandatory requirement, but is both useful and advisable.

Sometimes the necessary support spacing may be dictated by

the nature of the building fabric. If however the designer has

discretion over the spacing of supports the loading graphs can

be used to maximise this distance. This will reduce the number

of support components and fixings that will be required, thus

reducing the overall cost of the installed system.

Supports for cable tray (P2000)

Some of the Cablofil steel wire cable tray loading graphs are

denoted as P2000. This means setting supports at 2 metre apart

instead of 1.5 metres, thus enabling the installer to reduce,

a) the number of supports used and

b) the overall installation time.

Example:

Span 1500 : 100 m / 1.5 = 67 supports

Span 2000 : 100 m / 2 = 50 supports

Support of fittings

Cable tray fittings must always be provided with local support. The

illustrations opposite give recommended support positions.

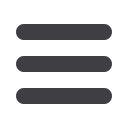

(vii) Location of couplers

In practice it is often impossible to predetermine where the

couplers will be located within a straight run of cable tray. However

it is well worth making some effort to roughly plan their position

during the early stages of installation.

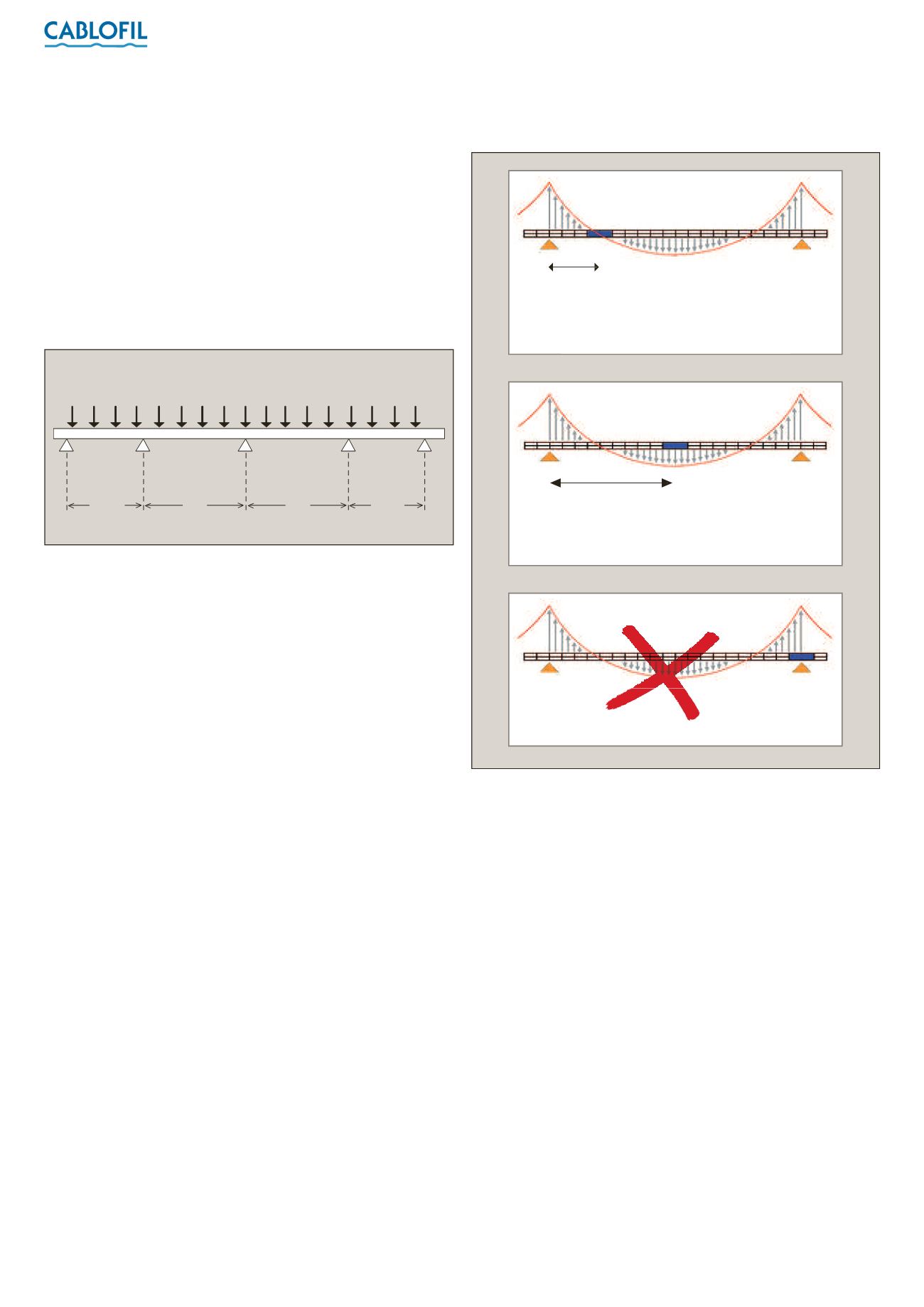

The worst positions for the couplers is directly underneath

a support.

The best position for joints in a continuous installation is one

quarter / one fifth of the span distance on either side of each point

of support.

3 /4

S

S

S

3 /4

S

Fully loaded

Short

span

Short

span

Full span

Full span

L/2

Possible

70% PERFORMANCE

If the coupling is at L/2, a coefficient of 0·7 should be

applied to the permissible load

100% PERFORMANCE

For best results, place the couplers at 1/4 or

1/5 of the way along the span

Optimum

L/4 or 5

Forbidden

Never put the support under the coupler