124

®

(x) Earth protection

Earthing an installation is vital for the safety of people and

property. Furthermore it plays an active role in EMC.

Definition

The earth network is made up of all the metallic components of a

building that are interconnected. These include beams, conduits,

cable management, the metal frames or devices. All such

elements must be interconnected to ensure the earth network is

equipotential.

Benefits of equipotential earthing network

The equipotential earth network works like a system of conduits

evacuating any fault currents and the parasite currents to earth.

This provides a means of :

• protecting people and property

• obtaining a satisfactory EMC performance level

Integrating steel wire cable tray into the earth network

In order to benefit from the advantages in terms of safety and

EMC, metallic cable trays must be connected to the earth network

every 15 m.

Where tray runs are shorter than 15 m, the ends of each metal

cable tray must be connected to earth.

Any electrical circuit thus formed by the cable tray must be closed

to help remove any fault or noise currents which may arise.

Role of the protective conductor :

The protective conductor

provides a simple and effective means of connecting the cable tray

to earth.

(xi) Electromagnetic compatibility (EMC)

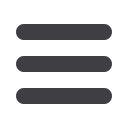

Understanding EMC involves the analysis of electromagnetic

pollution between a source of disturbance and its victim.

Definition

Electromagnetic interference is emitted by a source polluting a

victim. Electromagnetic interference is transmitted by a process

known as coupling. An EMC problem only occurs when the three

elements source, coupling and victim are evident. To obtain a good

EMC we simply need to eliminate one of the three elements or

reduce its effect.

Metallic cable trays with excellent electrical continuity, which are

integrated into an installation’s equipotential earthing network,

reduce the effects of coupling and therefore improve an electrical

installation’s EMC.

The solution offered by Cablofil steel wire cable tray

• Its open structure makes it easy to ensure correct separation by

visual inspection

• Its easy installation and metal structure guarantee excellent

electrical continuity in all cases : couplings, bends, changes of

level, crossovers etc.

• Its open structure can reduce ‘cross talk’

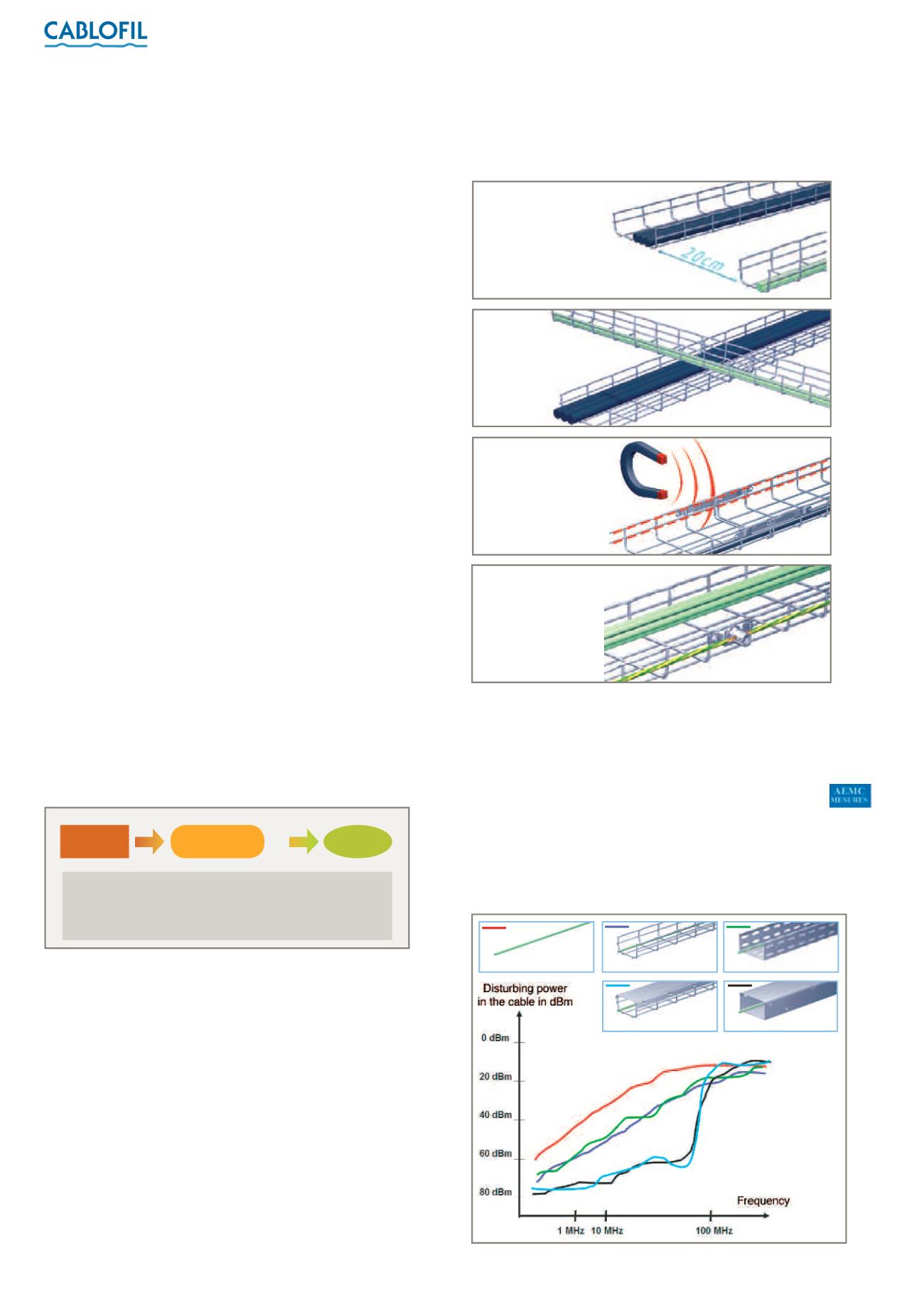

EMC tests

Tests conducted by the accredited and independent AEMC

Measures and CETIM laboratories demonstrate the performance

of Cablofil steel wire cable tray in relation to the EMC of the

electrical installation.

The golden rules!

1 :

The EN 50174-2 standard specifies how far cables must be kept apart. This

depends on the type of data cable, the number of power cables and the type of

cable tray. Otherwise, the distance of 20 cm provides a simple and sensible rule of

thumb. For precise details, please contact our technical support team on

+44 (0) 845 605 5334.

• Test 1 - configuration:

Data cable in an external electromagnetic field

A data cable (Category 5e UTP) is placed in an insulated anechoic

chamber and subjected to a powerful artificially-generated

electromagnetic field in order to simulate electromagnetic

interference.

Each tray is connected to earth and subjected to the test :

Source

Coupling

Victim

Sources include

– frequency modulators, mobile phones,

lightning, power cables, etc.

Victims include

– IT systems, devices, data cables, etc.

Make sure electrical

continuity is preserved :

use metal cable tray and

couplers.

Connect cable trays to

the earthing network

(every 15-20 m).

Make sure

different cable types

cross at right angles.

Remember the

importance of keeping

power and data cables

separate.

1

(EN 50174-2 standard)

Cable with no

metal tray (for comparison)

Cable in wire tray

Cable in perforated tray

Cable in

wire tray with cover

Cable in raceway with cover