125

Results and interpretations

A simple comparison of the measurements for the different

cable tray configurations - steel wire cable tray (wire mesh) and

perforated cable tray, with and without cover - makes it possible

to quantify the role played by cable tray in relation to EMC.

These tests show that there is no significant difference in

‘Faraday cage’ effect offered by steel wire cable tray (wire mesh)

or perforated cable tray.

These results show that it is vital :

• to use metal cable tray

• to earth the cable tray

• to use a cover if required

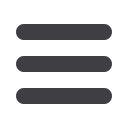

• Test 2 - configuration:

Data cable alongside a power cable

A Category 6 UTP data cable is placed inside an insulated

anechoic chamber and subjected to an electromagnetic field

generated by a power cable.

The following parameters are studied :

• Cable tray earthing

• Separation distances – 0, 10, 20, 30 cm

• Cable tray type – steel wire cable tray (wire mesh), perforated

cable tray, trunking

• Separated cable trays

• One cable trays, with and without dividers

As a result, a total of 118 configurations are tested.

Results and interpretations

This second test configuration confirms that metal cable trays

reduce interference - steel wire cable tray (wire mesh) and

perforated cable tray.

To obtain a good EMC, these results show that it is vital :

• To use metal cable tray

• To earth the cable tray

2

Loadings

First and foremost, steel wire cable tray must act as an effective,

resistant and durable support for cables.

The mechanical performance of all products and accessories is

tested against the very demanding requirements imposed by the

international standard IEC 61537.

Generation of electromagnetic interference by

injecting current into the power cable.

Measurement of the interference generated in the data cable.

A comparison of the impact of 3 of the 118 configurations

Interference

within the cable

in dBµV

Frequency

i) Safe working loads

The permissable load stated in this catalogue represents the

load that Cablofil steel wire cable tray is guaranteed to be able to

bear. It assumes loads are evenly spread and is given in daN/m.

The standard permits a deflection equivalent to 1/100th of the

span. Legrand imposes a stricter limit of 1/200th for both safety

and aesthetic reasons. For example, Legrand voluntarily restricts

deflection to 10 mm for a span of 2 m, whereas the standard

would allow 20 mm.

Load tests carried out to IEC 61537 (safety factor 1·7 + joint

1

/

5 th

of the way along the span). Permissable load should include all

cable loads and any other additional loads (eg: wind, snow).

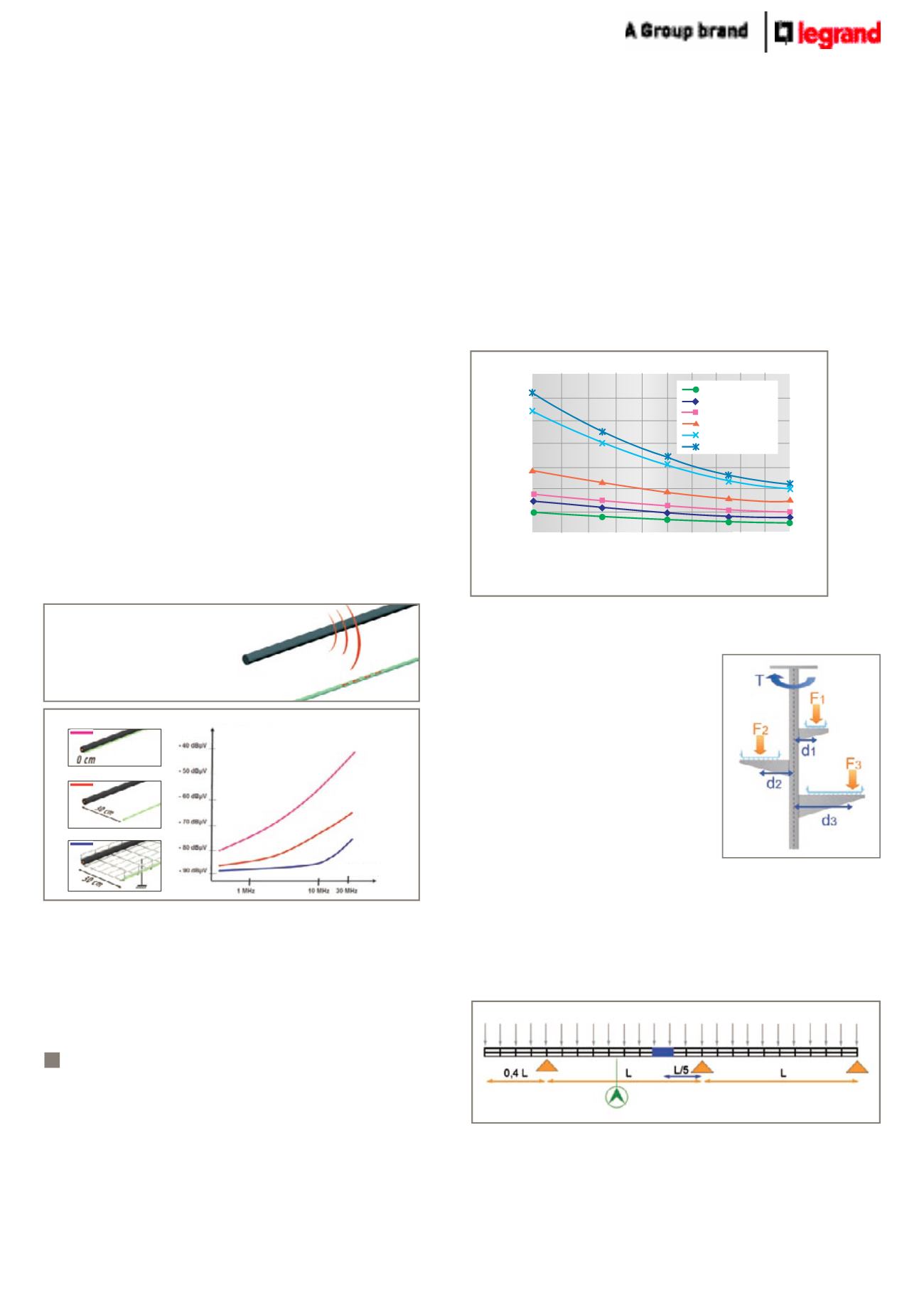

(ii) Safe working loads for supports

Brackets are classified by their permissible load (in daN).

Hangers are classified by their

permissible torque (in daN/m).

All Cablofil supports are tested and

comply with the IEC 61537 standard.

F

– is the load (in daN) applied to the

support.

d

– is the distance between the hanger

axis and the load.

T

– is the torque (in daN/m) applied to

the hanger.

Calculation rules :

Total F = F1 + F2 + F3

<

permissible

hanger load

Total T = F1.d1 + F3.d3 – F2.d2 < permissible hanger torque

(iii) Load tests : test configuration according to standard

IEC 61537

Each Cablofil steel wire cable tray has been tested in the required

configuration, with a coupling 1/5

th

of the way along the span.

Deflection is measured at the centre of the span.

The values given in this document have been obtained from

extensive testing of our cable support equipment. They are given

as a guide, so that customers may use Legrand’s products to

the best advantage; they are nevertheless average figures which

are given in good faith, but without accepting any liability in

contract, tort or otherwise in the event of different performance by

equipment which is actually supplied.

CF54 EZ, GC

Load (kg/m)

Span (mm)

100.0

140.0

80.0

60.0

40.0

20.0

0.0

2500

2300

2100

1900

1700

1500 1600

2000

1800

2200

2400

120.0

CF 54/50 to 100

CF 54/150

CF 54/200

CF 54/300

CF 54/400 to 500

CF 54/600

When the graph line is above the intersection of the required load and span lines,

the support equivalent is suitable for use within those load and span conditions.