119

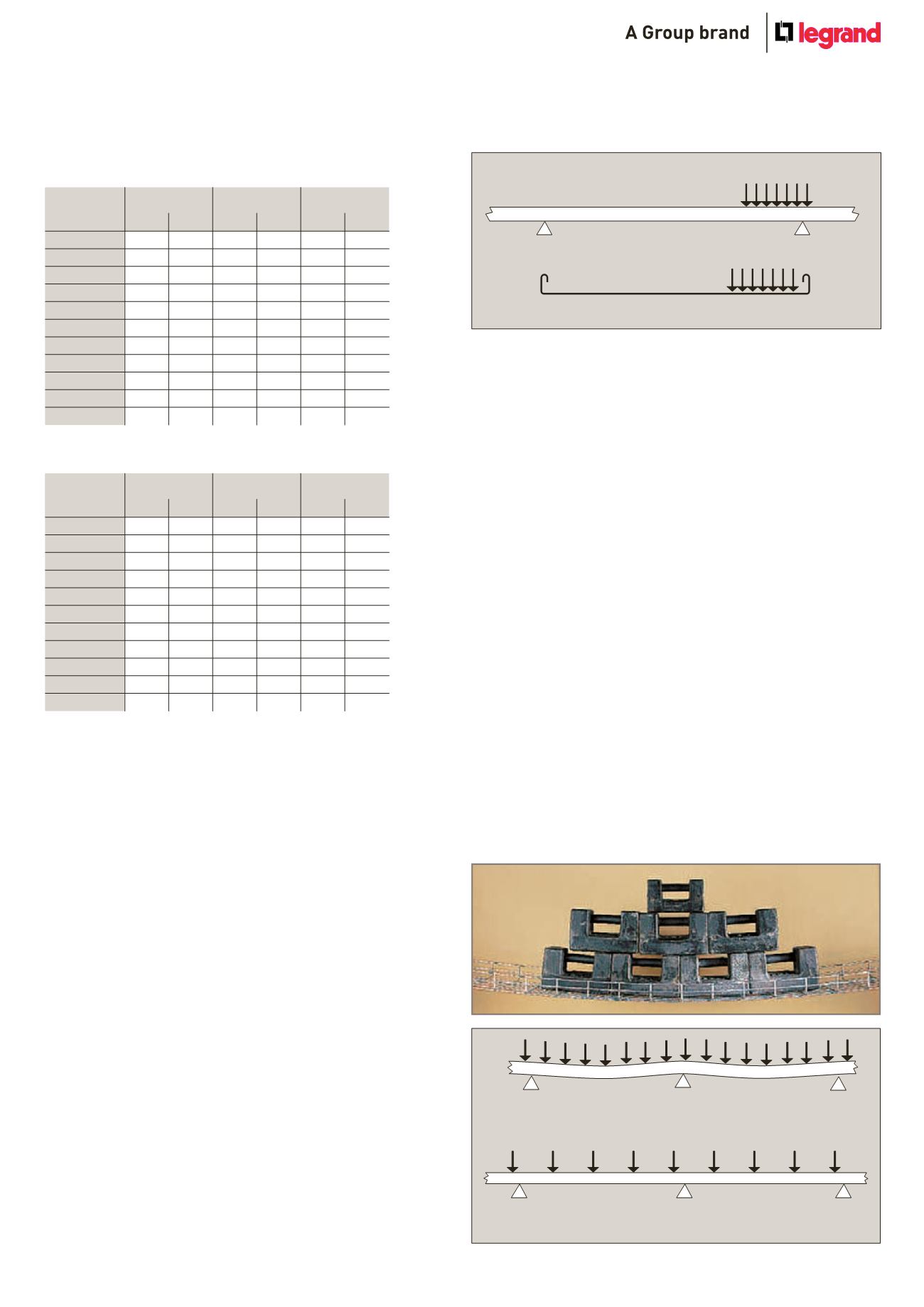

(ii) Point loads

Point loads may consist of permanent equipment, such as lighting

luminaires, junction boxes or other switchgear, or temporary

loads such as commissioning equipment or installation personnel,

however, consider ‘safety during the installation phase’.

Analysis of uniformly distributed loads (UDL), such as cables or

pipes is relatively simple but analysing the effect of a point load

is quite complex; fortunately a simple alternative approach is

available.

Firstly, one makes the reasonable assumption that the point

load will be situated in the worst position at mid-span. The force

this point load imposes can then be taken as equivalent to that

imposed by a load of twice its value uniformly distributed along

the span. Thus the point load can be converted to the equivalent

uniformly distributed load which is then added to other UDL’s to

produce one total uniform load.

Example:

Point load = 30 kg

Support spacing = 3 m

UDL = 100 kg/m

UDL equivalent to 30 kg point load =

2 x Point Load = 2 x 30 kg = 60 kg = 20 kg/m

Total UDL = 100 kg/m + 20 kg/m = 120 kg/m

The suitability of a tray to carry this total load can then be

considered using the loading graph information (see p. 125).

Although this treatment does assume the point load will be in the

‘worst case’ position, the installer should, given discretion, always

position any point load as close as possible both to a support and

to either side flange, minimising the stress on the installation, as

per the following illustration.

(iii) Snow, wind and external forces

The loading graphs show the maximum safe working steady load

for each type of support system. If the system is outdoors and

must also sustain snow, ice, wind or other variable forces these

must also be taken into account at the design stage.

Appropriate design data for UK weather conditions is given in

British Standard BS EN 1991.

(iv) Safety factor

To arrive at a safe working load (SWL) for each type of equipment

Legrand test their products to find the ultimate failure load. The

SWL is obtained by dividing the load before failure by a factor of

1·7 minimum.

This safety factor may need to be increased by the designer

depending upon the circumstances. For example, if the support

system is expected to be subject to aggressive abuse a safety

factor as high as three or more may be used. Such treatment is,

however, the exception and care should be taken not to

over-design the system by using an unnecessarily high

safety factor.

(v) Deflection

The deflection of a cable tray under load is not directly related to

its strength but it is obviously of aesthetic importance. For this

reason it may be necessary to estimate the likely deflection whilst

designing an installation, especially if it will be in a highly visible

location. Experience has shown that in order to maintain a degree

of deflection which is subjectively acceptable to the eye, the load

on the cable tray will often be restricted to well below its safe

maximum.

In the event of critical overload, a steel wire cable tray (wire mesh)

structure becomes like a hammock.

W

W

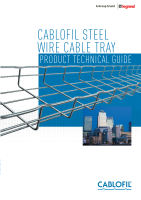

Table 3 : PVC unarmoured stranded copper power

cables to BS 6346

Nom. area

2 core

3 core

4 core

of conductor

(mm

2

)

kg/m D in mm

kg/m D in mm

kg/m D in mm

25

0·7

18·4

1·0

20·4

1·3

22·7

35

0·9

20·0

1·3

22·4

1·7

25·0

50

1·2

22·2

1·7

25·4

2·3

28·6

70

1·7

24·6

2·4

28·4

3·1

32·2

95

2·3

28·2

3·3

33·1

4·3

37·2

120

2·8

30·9

4·0

36·0

5·3

40·6

150

3·5

34·1

4·9

39·7

6·5

45·0

185

4·2

37·8

6·1

44·1

8·0

49·8

240

5·5

43·2

8·0

49·6

10·6

56·2

300

7·0

47·2

9·7

55·0

13·2

62·5

400

8·5

53·2

12·6

61·4

16·7

69·6

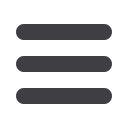

Table 4 : PVC armoured stranded copper power cables

to BS 6346

Nom. area

2 core

3 core

4 core

of conductor

(mm

2

)

kg/m D in mm

kg/m D in mm

kg/m D in mm

25

1·3

23·0

1·7

25·1

2·1

27·5

35

1·6

24·8

2·1

27·3

2·6

30·0

50

2·0

27·2

2·6

30·5

3·5

34·8

70

2·5

29·5

3·6

34·8

4·5

38·4

95

3·5

34·4

4·6

39·1

5·9

43·3

120

4·1

37·1

5·5

41·9

7·5

48·1

150

4·9

40·2

7·0

47·2

8·8

52·3

185

6·3

45·1

8·4

51·4

10·7

57·5

240

7·8

50·5

10·7

57·3

13·5

63·9

300

9·3

55·4

12·7

62·6

16·4

69·9

400

11·3

60·8

15·7

68·8

21·3

78·8

Reduce load to reduce deflection

Safe, but visually unacceptable