117

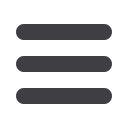

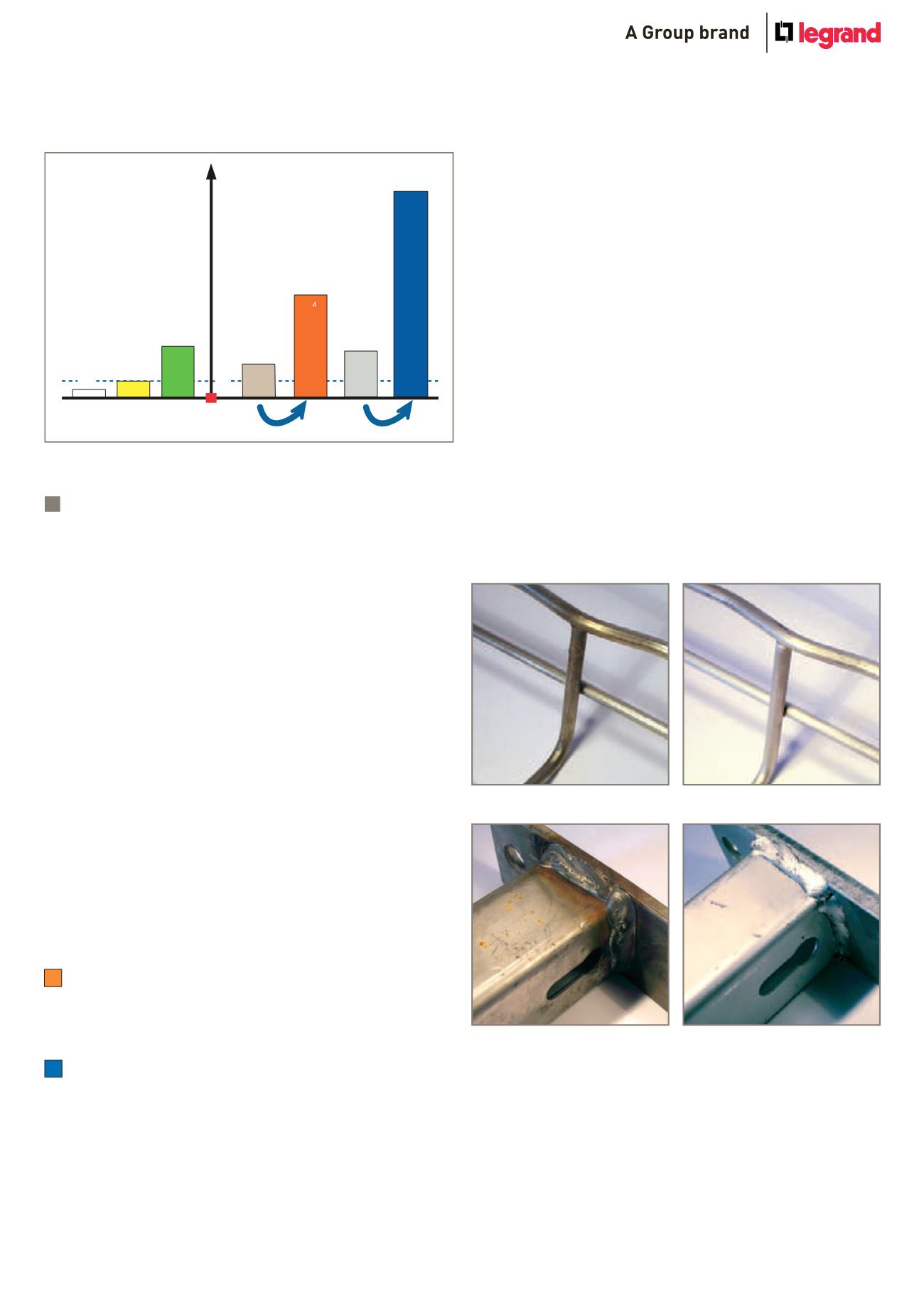

Pickling and passivation

A stainless steel surface will have excellent corrosion resistance

due to the chromium oxide layer on the surface of the product.

With some stainless steels however, the surface areas can

become subject to corrosion due to the depletion of chromium

during welding, or the introduction of iron during a machining

process (not applicable to most cable management products).

Where a uniform appearance is important after carrying out

welding processes, it is often specified that all surfaces should

be pickled and passivated to remove the smoke stain from the

welding process. Also where extreme corrosion resistance is

called for, this process may help to remove crevice corrosion from

around the welding area.

Pickling

The pickling process involves the article being immersed in a

blend of acids which dissolve iron and iron oxides which adhere to,

or are embedded in, the surface of the stainless steel. These acids

cause a removal of the surface layer of between 1 and 3 microns.

The article is finally rinsed with water to complete this stage of

the process.

Passivation

Passivation of the stainless steel will occur naturally after pickling

when the oxygen in the air will react with the surface of the steel

to form a passive chromium oxide layer. However it is usual for

this passivation process to be speeded up by immersing the article

in a nitric acid or other passivating agent.

Pickling and passivation gives Cablofil stainless steel wire cable

tray a very light grey colour and a distinctly matt finish.

All Cablofil stainless steel products are pickled and passivated.

2

Stainless steels

For all practical purposes most stainless steel services supports

can be regarded as maintenance free and suffering no corrosion.

Inevitably there is a relatively high price to pay for these attractive

properties but, in aggressive environments or where the cost

or inconvenience of gaining subsequent maintenance access is

prohibitive, this initial cost premium may well be justified.

Background

Stainless steel contains a high proportion of chromium (usually

at least 17%) and the steel’s remarkable immunity to corrosive

attack is conferred by the chromium-rich oxide film which occurs

naturally on its surface. This invisible film is not only inert and

tightly bonded to the surface, it also re-forms quickly if the

surface is damaged in any way.

The fire resistance of stainless steel is particularly noteworthy;

tests have demonstrated that stainless steel cable supports can

be expected to maintain their integrity for considerable periods

even when exposed to direct flame temperatures exceeding

1,000°C. This may be an important consideration where the

electrical circuits being supported provide for emergency power

or control systems.

Stainless steel is also used where hygiene is a major

consideration. Its advantages in such applications are again its

excellent resistance to the various chemicals and washes which

are frequently used for cleaning purposes and the smoothness of

surface (depending on the finish specified) which minimises the

soiling or contamination that can take place.

Stainless steel 304 L

EN 10088-2 standard AISI 304L – X2CrNi18.09 – 1.4307

Offers good corrosion resistance against soft water, normal

environments and food products (except mustard and white wine).

Stainless steel 316 L

EN 10088-2 standard AISI 316L – X2CrNiMo17.12.2 – 1.4404

Since it contains molybdenum, stainless steel 316L is able to

resist intergranular corrosion. This makes it particularly suitable

for the chemical and food industries, the nitrate explosives

industry and environments containing halogen (fluorine and

chlorine).

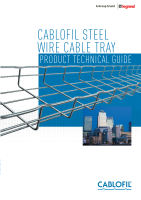

100

200

400

600

800

1000

1200

1400

1500

Pickled

& passivated

Pickled

& passivated

316L

Un-

treated

Un-

treated

Stainless

steel

Carbon

steel

304L

316L

EZ

GS

GC

304L

x 4

x 5

300

Figures for salt spray tests, baseline 100 hours : EZ

316L

304L

Pickled and passivated

Untreated

Pickled and passivated

Untreated