118

®

Cable tray systems are intended for the support of a combination

of cables, electrical equipment and/or communication system

installations. Where necessary cable tray systems may be used

for the segregation of cables.

Note : these systems are designed for use as supports for cables

and not as enclosures giving full mechanical protection.

These systems are covered by BS EN 61537.

1

Design factors to consider

Consideration should be given to the following factors when

undertaking the design of a support system although some

of these (e.g. snow/wind loads) may not be relevant to every

installation.

(i) Distributed loads (eg. cables, pipes)

(ii) Point loads

(iii) Snow, wind and external forces

(iv) Safety factor

(v) Deflection

(vi) Spacing of supports

(vii) Location of couplers

(viii) Testing of cables within a support system

(ix) Electrical continuity

(x) Earth protection

(xi) Electromagnetic compatibility (EMC)

The following sections provide a wealth of useful information on

each of these design aspects.

(i) Distributed loads

Before commencing the design process for a new installation

it is usual to consider whether future changes in the pattern

of demand for building services will impose increased loading

requirements on the support system. If so, it is good design

practice to allow both the physical space and sufficient load

carrying capacity for the future addition of 25% more cables or

other loading medium.

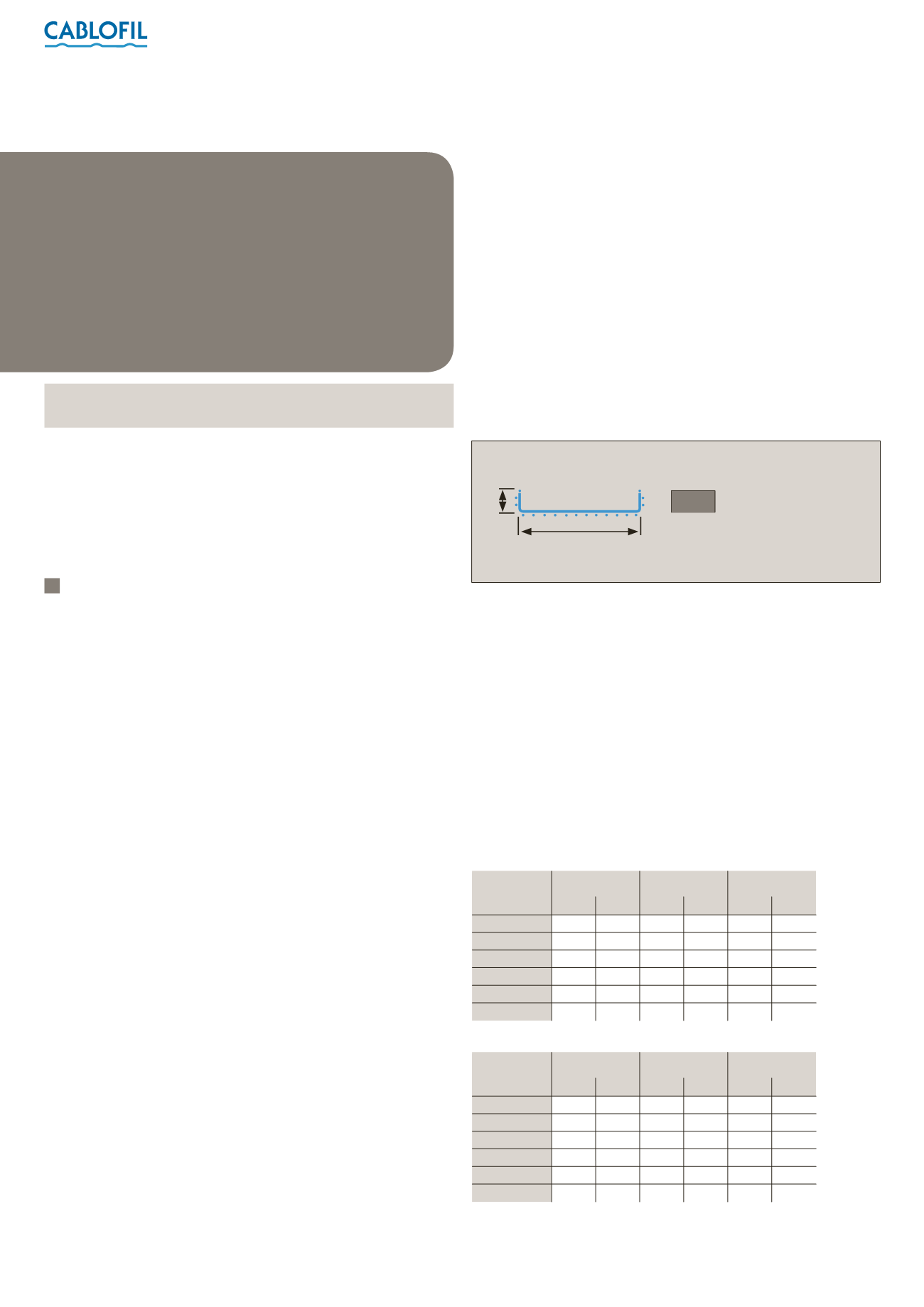

Estimation of cable loads

If full details of the cabling layout are available then the likely

cable load can be calculated using either manufacturer’s

published information or the tables of cable weights and

diameters which are given opposite. However, it is often necessary

to select a tray design in the absence of accurate information

on the likely cable load. To assist this selection process a useful

approach can be to choose a likely size of tray and then to

estimate the maximum cable weight which is capable of being

contained within it. This estimate may be arrived at using the

following guide :

Steel wire cable tray systems

IN THIS SECTION...

Steel wire cable tray

systems

1. Design factors to consider

2. Loadings

Installation of

services

Table 1 : PVC armoured power/control cables to BS 6346

Nom. area

2 core

3 core

4 core

of conductor

(mm

2

)

kg/m D in mm

kg/m D in mm

kg/m D in mm

1·5

0·3

12·3

0·3

12·8

0·4

13·5

2·5

0·4

13·6

0·4

14·1

0·5

15·0

4·0

0·5

15·1

0·5

15·8

0·7

17·8

6·0

0·6

16·5

0·7

18·0

0·9

19·2

10·0

0·9

20·1

1·0

21·2

1·2

22·8

16·0

1·0

21·9

1·2

23·1

1·7

26·3

Table 2 : PVC insulated and sheathed circular surface wiring

Nom. area

2 core

3 core

4 core

of conductor

(mm

2

)

kg/m D in mm

kg/m D in mm

kg/m D in mm

1·5

0·1

7·7

0·1

8·2

0·1

9·1

2·5

0·1

9·2

0·2

9·7

0·2

10·6

4·0

0·2

10·2

0·3

11·0

0·3

12·6

6·0

0·2

12·0

0·3

12·8

0·4

14·2

10·0

0·4

14·6

0·5

15·6

0·7

17·4

16·0

0·6

16·9

0·7

18·0

0·9

20·0

Note :

this formula only provides an estimate of the maximum

load which can be physically contained within a tray. The ability of

that tray to support such a load depends upon the spacing of its

supports.

Cable weights and diameters

Tables 1 and 2 below give typical weights and diameters (D) for

PVC sheathed, steel wire armoured cables with stranded copper

conductors.

Tables 3 and 4 give typical weights and diameters for PVC

sheathed, unarmoured stranded copper power cables. Cables with

XLPE (cross linked polyethylene) insulation are usually slightly

lighter so the information given may also be used for these cables

too.

Values show approx. weight and diameter of typical cables.

D = Overall cable diameter.

Max. cabling capacity (kg/m) = cable laying area (m

2

) x 2800

Cable laying area (m

2

) = W (m) x H (m)

Applicable to cable tray

W

H

Cable laying area