116

®

Coated and stainless steels

IN THIS SECTION...

Coated and stainless steels

1. Coated steels

2. Stainless steels

Finishes

will be gradually corroded in preference to the underlying steel.

Corrosion products from the zinc will also be deposited onto

the steel, effectively re-sealing the surface and maintaining the

integrity of the barrier.

NOTE

: Any white marks due to the formation of zinc

hydroxycarbonate which might appear on the surface have no

influence on the corrosion resistance. This is in fact the very

principle on which galvanic protection is based.

Geomet

®

Geomet is a treatment based on zinc and aluminium. As it

does not contain any chromium VI (hexavalent), it complies with

the RoHS Directive.

Offering protection equivalent to GC, it is used for small

accessories and fixings which are difficult to hot dip galvanise.

EZ+

EZ+ is an additional organic finish applied over standard

electrozinc plated steel wire cable trays, offering a durable

surface treatment for temporary external installations during the

construction phase.

Cablofil EZ+ brings with it a Class 6 alternative to a hot dip

galvanised finish (GC) according to IEC 61537. Salt spray tests

carried out demonstrate that EZ+ exceeds the performance of

a standard hot dip galvanised finish (no red rust after more than

550 hours exposure to salt spray test, according to ISO 61537).

The same ‘Class 6’ classification is achieved after products are

subjected to a simulated 2 year ageing process under

UV conditions.

Z+

Alloy compound of 94% zinc, 3% aluminium and 3%

magnesium, coated steel with high elastic yield. Compatible with

hot dip galvanised products and has Class 8 properties according

to IEC 61537. Products self-regenerate when cut. Z+ products are

compatible with hot dip galvanised / EZ+.

Powder coated

Resin-based paint is applied to the steel wire cable tray using an

electrostatic powder and then cured in an oven. The entire range

of RAL colours can be obtained. Mainly used for aesthetic reasons

and to help identify cable routes, it offers very good corrosion

resistance.

Z+

EZ+

1

Coated steels

Pre-galvanised

EN 10346 (accessories only)

Before manufacture, a coating of zinc is deposited by continuous

immersion on to the steel.

Electrogalvanising after manufacture

1

EN 12329 standard

This coating process is often referred to as bright zinc plating

(BZP). Electroplating with zinc may be used when a smooth bright

decorative finish is required. Parts can be coloured or colourless

depending on the type of passivation process used. It is generally

used for internal applications where a low degree of corrosion

resistance is acceptable. Electroplating involves connecting the

metal substrate to a negative terminal of a direct current source

and another piece of metal to a positive pole, and immersing both

metals in a solution containing ions of the metal to be deposited,

in this case zinc.

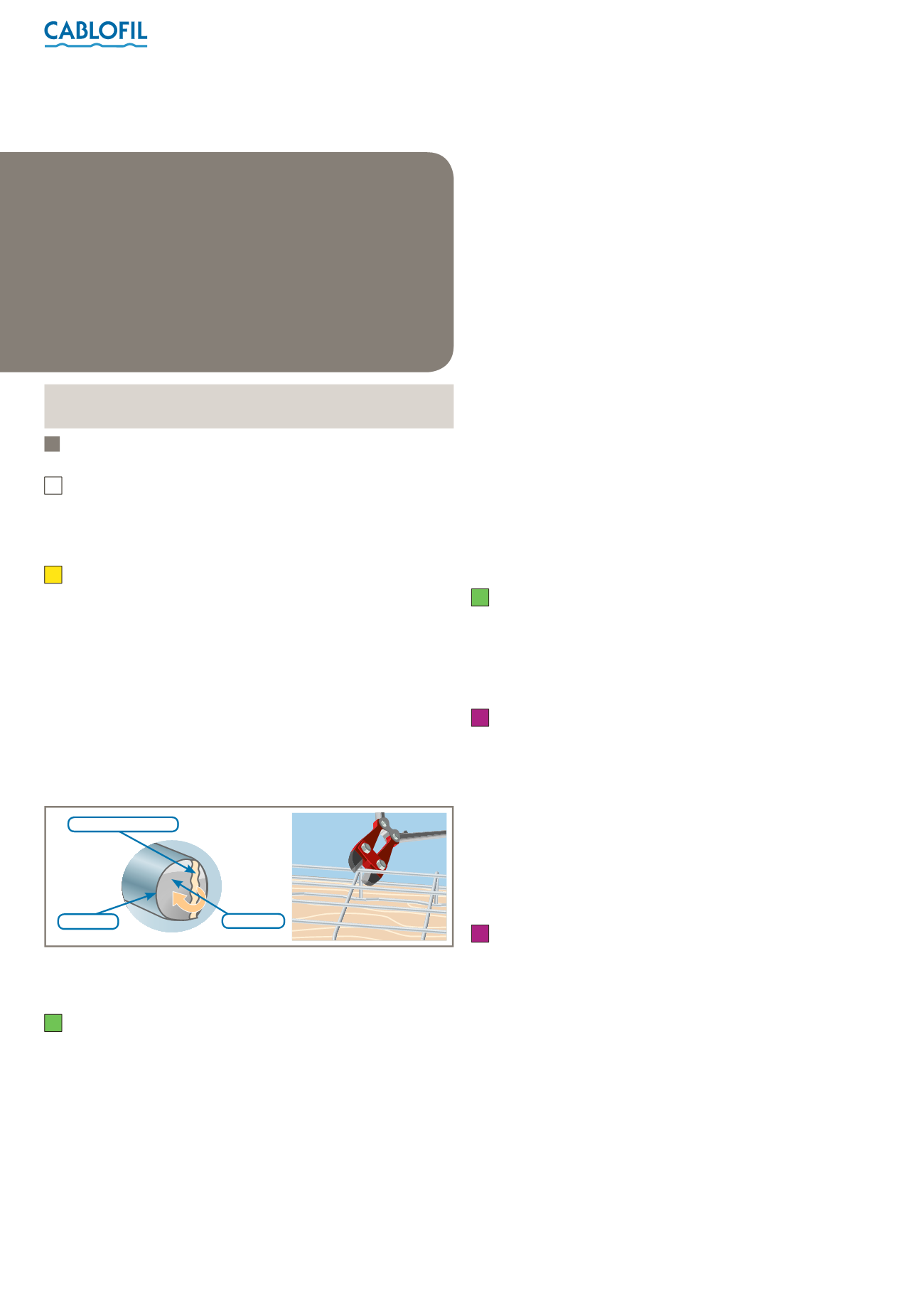

Ongoing protection

When steel wire cable tray is cut, the level of protection is not

affected. The jaws of the bolt cropper drag a layer of zinc across

the cut end which forms a protective layer.

Hot dip galvanised after manufacture

BS EN ISO 1461 standard

Hot dip galvanising after manufacture is an excellent, economical

protective finish used on support systems in many industrial and

commercial applications.

Background

The galvanised coating is applied as a final manufacturing process

by immersing a steel component (after various pre-treatments) in

a large bath of molten zinc; the zinc forms an alloy with the steel

substrate and protects the steel from corrosion in two ways.

Firstly, the zinc coating surrounds the base steel with a total,

tough physical barrier preventing corrosion of the steel by the

surrounding atmosphere. Secondly, if steel does become exposed,

e.g. at a cut edge, the zinc coating acts as a sacrificial anode and

Zn anode

Zinc hydroxide

Fe cathode

GS

EZ

GC

DC

1:

BEAMA ‘BEST PRACTICE GUIDE TO CABLE LADDER AND CABLE TRAY INSTALLATIONS’