Technical Hotline

+44 (0)1268 563720

645

CABLE MANAGEMENT

PERIMETER AND

DISTRIBUTION

TECHNICAL SPECIFICATION

MATERIALS

PVCu materials used in the manufacture of MK

products are self extinguishing non-flame propagating

in accordance with BS 4678 Part 4.

Extrusion material has been tested by a UKAS

accredited laboratory in accordance with the

requirements of BS 476 Part 7 and has achieved a

Class 1Y.

Moulding material has been tested by a UKAS

accredited laboratory and conforms with IEC 695-2-1

at a severity of 650°C

IET WIRING REGULATIONS

Designed and manufactured to comply in all respects

with BS 7671:2008 (IET Wiring Regulations 17th

Edition: 2008)

QUALITY ASSURANCE

The system is manufactured to BS EN ISO 9001

Classifications to BS EN 50085-1:2005 and

BS EN 50085-2-1:2006 available on request

For a full range of corresponding products,

see pages 338-343 in the product selector.

Premier Technical

FIGURE 1

FIGURE 2

Integrated Trunking

Description

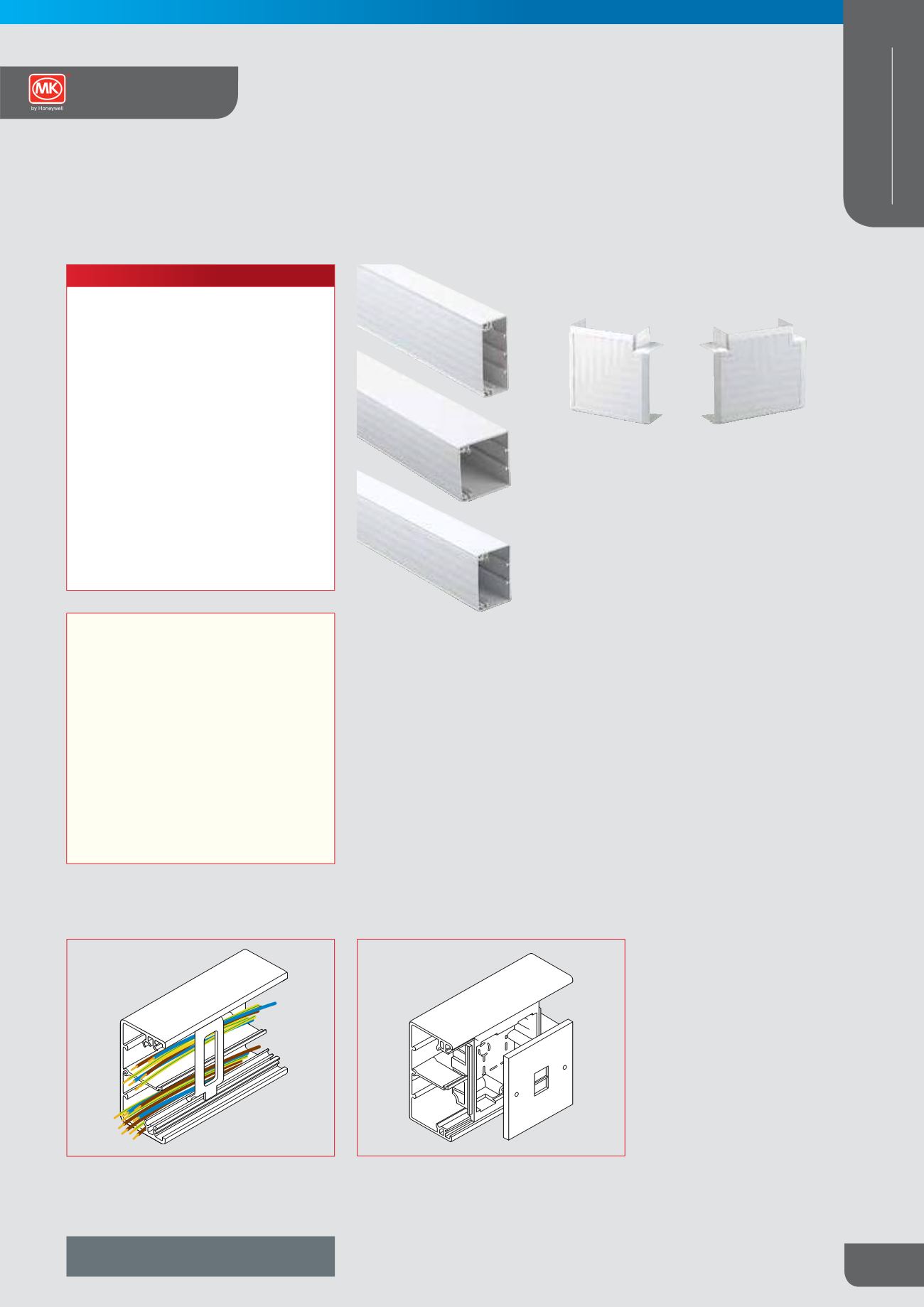

Premier is an integrated PVCu trunking system for general cable distribution. A

comprehensive range of tees, angles and junctions make a very wide range of

configurations possible and the system can be wall or ceiling mounted.

6 trunking sizes are available (see dimensions overleaf) offering the user distribution

solutions, from incoming mains to the most remote power, telecom or data outlet.

Cable segregation (see figure 1) Each trunking profile incorporates a series of

preformed locators which accept clip-in dividers for cable segregation. Clip-in

components are provided for retaining cables within each compartment prior to

trunking lids being fitted.

FINISH

Premier lid components are decoratively textured in contrasting linear patterns

giving a subtle ‘striped’ effect.

All other components are in white with a semi matt finish.

FEATURES

l

Wide range of integrated components maximise

versatility in application

l

Simple, clean lines

l

Easy to assemble and install

l

Data bend option 32mm radius

l

High impact resistance and durability

l

Tapered joints provide complete protection at

junctions masking cut ends

l

Clip on covers provide continuous access for

wiring modifications

l

All extrusions manufactured from 100%

recycled material*

* Based on 2014 consumption