mkelectric.co.uk

mkelectric.co.uk

642

CABLE MANAGEMENT

PERIMETER AND

DISTRIBUTION

Pinnacle Technical

GENERAL NOTES

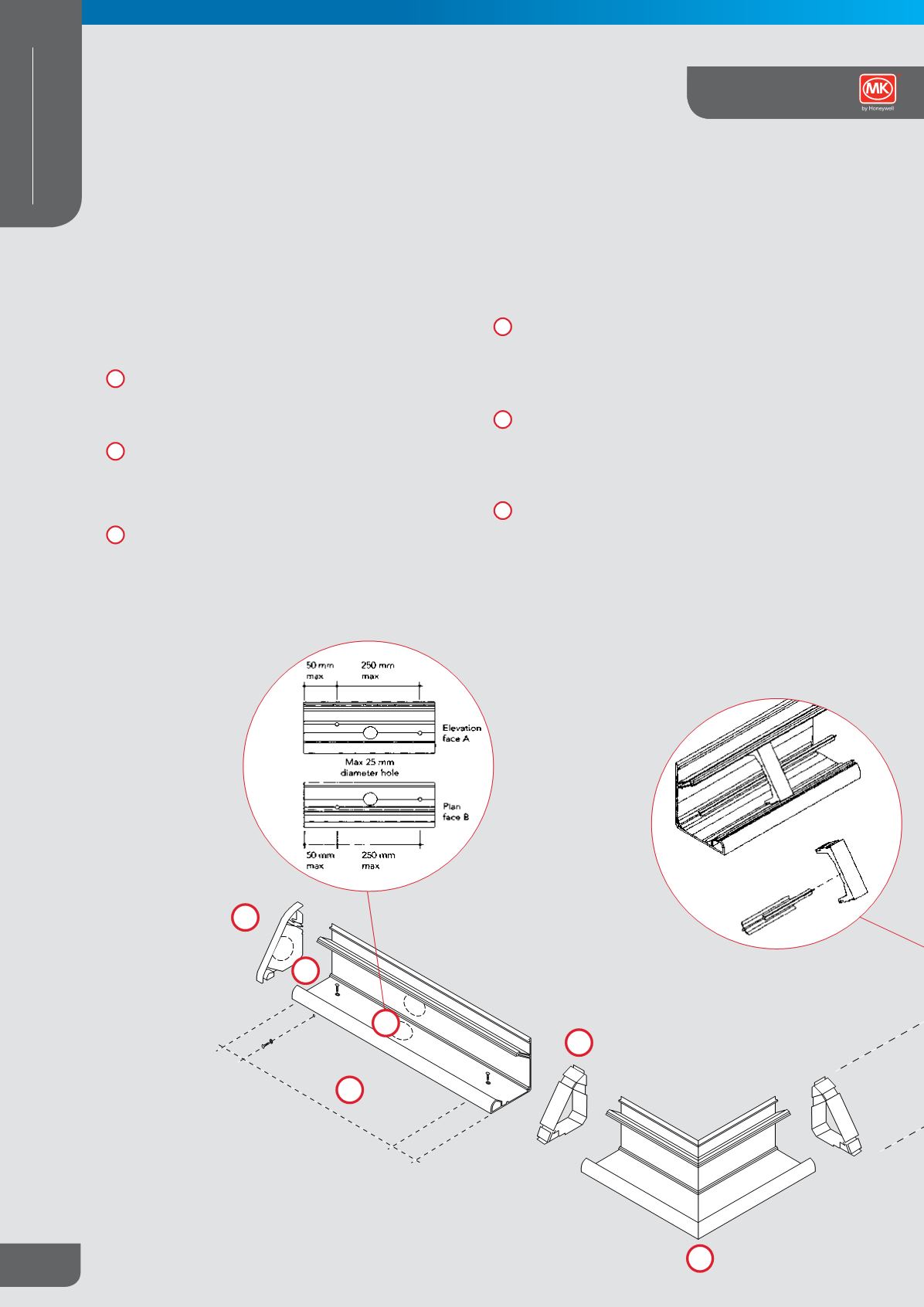

Prior to installation strike a line of trunking using a plumb and

chalk line for vertical, and spirit levels for horizontal runs.

INCOMING SUPPLY CABLES

Establish location of incoming cable supplies. Entry into

the trunking can be from the back, base or end caps and is

achieved by drilling up to a 25mm hole using the drill base

centres in the trunking and inserting a conduit gland.

Holes of 20mm can be drilled into the end caps for access

to the large compartment using one of a series of moulded

drill centres.

FIXING

Trunking requires fixing at staggered centres, 250mm

maximum along the length with the first and last fixing not

more than 50mm from the end of each length. Drill trunking

with 6mm holes using drill guides and fix with pan or round

head screws and washers (Note: Tighten screws firmly and

back off slightly to allow for movement). For double trunking

installation fix both bases this way.

Couplers – Always use a trunking coupler and cover at the

junction between each length and at corners to maintain IP4X

Classification. To fix push the coupler carrier onto the end of

the free trunking length. Slide up to fixed trunking and push

home.

Internal and External Corners – Remove covers. Push a

coupler onto each end and assemble to trunking. Position

trunking and corner. Check that the internal corner base

fits snugly into the corner. Fix trunking base as previously

described.

End caps – Having located the length of trunking and cut if

required push fit the end cap firmly onto the trunking ensuring

that it is butted up tight. Note: where greater retention is

required use MK adhesive EW PLUS to bond the end cap to

the trunking base only. Avoid adhesive contact with covers.

1

2

3

4

5

6

50mm

250mm

50mm

1

2

3

4

5

6

Installation Guide