16/12

Total Solution to Earthing & Lightning Protection |

9AKK106354A3360

16

Technical reference

IEC/BS EN 62305-3 - Physical damage to structures & life hazard

Non-conventional air termination systems

A lot of technical (and commercial) debate has raged over

the years regarding the validity of the claims made by

the proponents of such systems. This topic was discussed

extensively within the technical working groups that compiled

IEC/BS EN 62305. The outcome was to remain with the

information housed within this standard.

IEC/BS EN 62305 states unequivocally that the volume or

zone of protection afforded by the air termination system

(e.g. air rod) shall be determined only by the real physical

dimension of the air termination system. This statement is

reinforced within the 2011 version of BS EN 62305, by being

incorporated in the body of the standard, rather than forming

part of an Annex (Annex A of IEC/BS EN 62305-3:2006).

Typically if the air rod is 5 m tall then the only claim for

the zone of protection afforded by this air rod would be based

on 5 m and the relevant class of LPS and not any enhanced

dimension claimed by some nonconventional air rods.

There is no other standard being contemplated to run

in parallel with this standard IEC/BS EN 62305.

Natural components

When metallic roofs are being considered as a natural air

termination arrangement, IEC/BS EN 62305 offers

guidance on the minimum thickness and type of material

under consideration, as well as additional information

if the roof has to be considered puncture proof from a

lightning discharge (see Table 10).

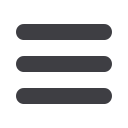

Table 11:

Typical values of the distance between down conductors according

to the Class of LPS (IEC/BS EN 62305-3 Table 4)

Class of LPS

Typical distances

I

10 m

II

10 m

III

15 m

IV

20 m

Down conductors

Down conductors should within the bounds of practical

constraints take the most direct route from the air termination

system to the earth termination system. The greater the

number of down conductors the better the lightning current

is shared between them. This is enhanced further by

equipotential bonding to the conductive parts of the structure.

Lateral connections sometimes referred to as coronal bands

or ring conductors provided either by fortuitous metalwork or

external conductors at regular intervals are also encouraged.

The down conductor spacing should correspond with the

relevant class of LPS (see Table 11).

There should always be a minimum of two down conductors

distributed around the perimeter of the structure. Down

conductors should wherever possible be installed at each

exposed corner of the structure as research has shown these

to carry the major part of the lightning current.

Table 10:

Minimum thickness of metal sheets or metal pipes in air termination

systems (IEC/BS EN 62305-3 Table 3)

Class of LPS

Material

Thickness

(1)

t Thickness

(2)

t’

I to IV

Lead

–

2.0 mm

Steel (stainless, galvanized) 4 mm

0.5 mm

Titanium

4 mm

0.5 mm

Copper

5 mm

0.5 mm

Aluminium

7 mm

0.65 mm

Zinc

–

0.7 mm

(1)

Thickness t prevents puncture, hot spot or ignition

(2)

Thickness t’ only for metal sheets if it is not important to prevent puncture, hot spot or

ignition problems