Total Solution to Earthing & Lightning Protection |

9AKK106354A3360

16/13

16

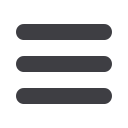

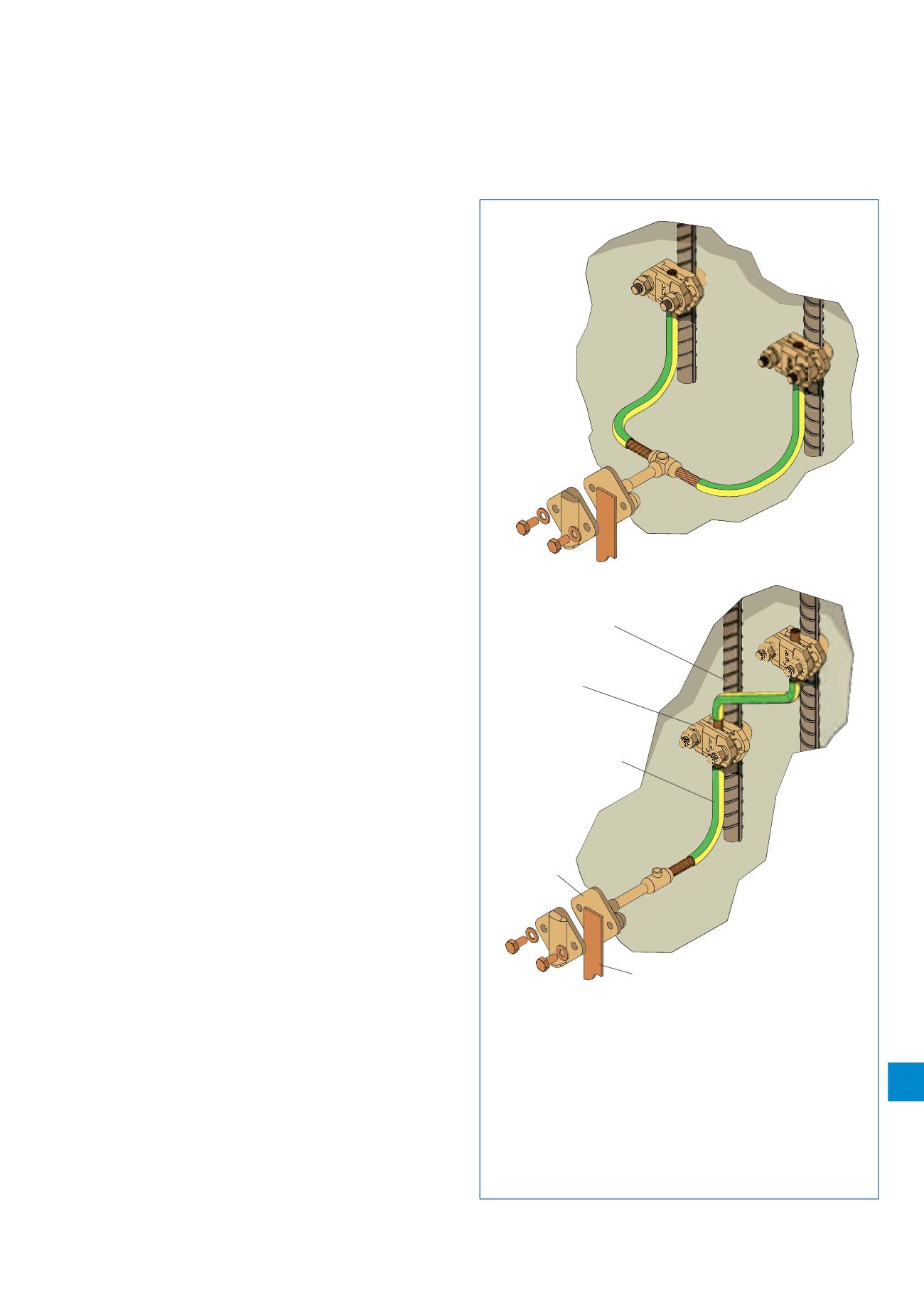

Figure 11. Typical methods of bonding to steel reinforcement within concrete

Natural components

IEC/BS EN 62305 encourages the use of fortuitous metal

parts on or within the structure to be incorporated into

the LPS. That these are welded, clamped with suitable

connection components or overlapped a minimum of 20 times

the rebar diameter. This is to ensure that those reinforcing

bars likely to carry lightning currents have secure connections

from one length to the next.

When internal reinforcing bars are required to be connected

to external down conductors or earthing network either of

the arrangements shown in Figure 6 is suitable. If the

connection from the bonding conductor to the rebar is to be

encased in concrete then the standard recommends that

two clamps are used, one connected to one length of rebar

and the other to a different length of rebar. The joints

should then be encased by a moisture inhibiting compound

such as Denso tape.

If the reinforcing bars (or structural steel frames) are to be

used as down conductors then electrical continuity should be

ascertained from the air termination system to the earthing

system. For new build structures this can be decided at

the early construction stage by using dedicated reinforcing

bars or alternatively to run a dedicated copper conductor

from the top of the structure to the foundation prior to

the pouring of the concrete. This dedicated copper

conductor should be bonded to the adjoining/adjacent

reinforcing bars periodically.

If there is doubt as to the route and continuity of the

reinforcing bars within existing structures then an external

down conductor system should be installed. These should

ideally be bonded into the reinforcing network of the

structures at the top and bottom of the structure.

Stranded copper cable

(70 mm

2

PVC insulated)

Cast in

non-ferrous

bonding

point

Bonding conductor

Clamped cable to rebar

connection

Steel reinforcement within

concrete (rebar)