Total Solution to Earthing & Lightning Protection |

9AKK106354A3360

16/15

16

Internal LPS design considerations

The fundamental role of the internal LPS is to ensure the

avoidance of dangerous sparking occurring within the

structure to be protected. This could be due, following a

lightning discharge, to lightning current flowing in the

external LPS or indeed other conductive parts of the

structure and attempting to flash or spark over to internal

metallic installations.

Carrying out appropriate equipotential bonding measures or

ensuring there is a sufficient electrical insulation distance

between the metallic parts can avoid dangerous sparking

between different metallic parts.

Lightning equipotential bonding

Equipotential bonding is simply the electrical interconnection

of all appropriate metallic installations/parts, such that in the

event of lightning currents flowing, no metallic part is at a

different voltage potential with respect to one another. If the

metallic parts are essentially at the same potential then the

risk of sparking or flashover is nullified.

This electrical interconnection can be achieved by natural/

fortuitous bonding or by using specific bonding

conductors that are sized according to Tables 8 and 9

of IEC/BS EN 62305-3.

Bonding can also be accomplished by the use of surge

protective devices (SPDs) where the direct connection with

bonding conductors is not suitable.

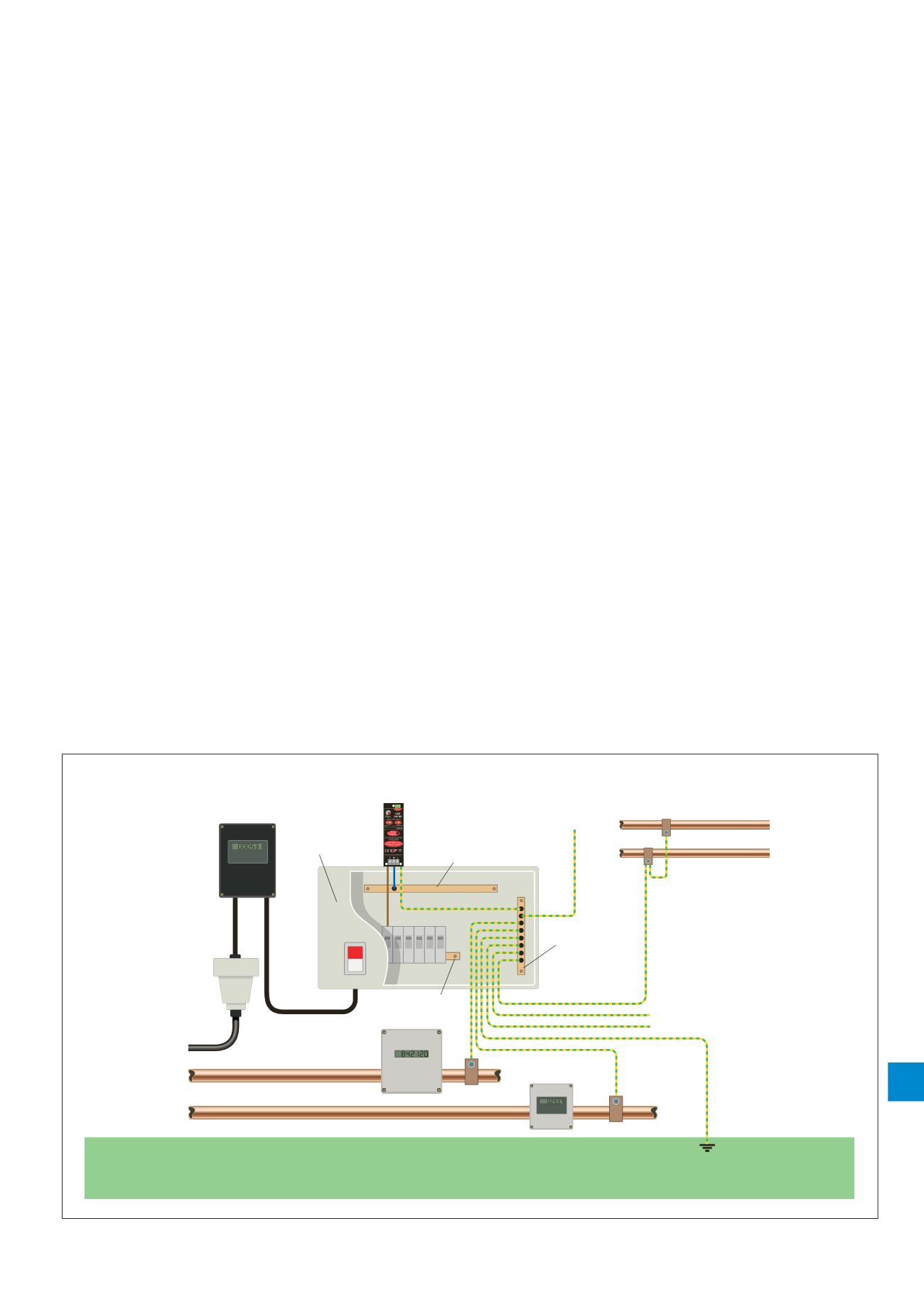

Figure 7 (which is based on IEC/BS EN 62305-3 fig E.43)

shows a typical example of an equipotential bonding

arrangement. The gas, water and central heating system are

all bonded directly to the equipotential bonding bar located

inside but close to an outer wall near ground level. The power

cable is bonded via a suitable SPD, upstream from the electric

meter, to the equipotential bonding bar. This bonding bar

should be located close to the main distribution board (MDB)

and also closely connected to the earth termination system

with short length conductors. In larger or extended structures

several bonding bars may be required but they should all be

interconnected with each other.

The screen of any antenna cable along with any shielded

power supply to electronic appliances being routed into the

structure should also be bonded at the equipotential bar.

Further guidance relating to equipotential bonding, meshed

interconnection earthing systems and SPD selection can be

found in the Furse guide to BS EN 62305.

Equipotential

bonding bar

Structural lightning

protection system

Central heating system

Screen of antenna cable

Electronic appliances

Power from utility

Meter

Meter

Gas

Water

Electricity

meter

Consumer unit/

fuseboard

SPD

ON

OFF

Neutral bar

Live bar

N

Figure 12. Example of main equipotential bonding