TSC-0912 - 09.10.12

Furse, Wilford Road, Nottingham, NG2 1EB • Tel: +44 (0)115 964 3700 • Email:

enquiry@furse.com• Web:

www.furse.comESP PCB/D & PCB/TN Series

Suitable for wave soldering

Very low let-through voltage (enhanced protection to BS EN 62305)

between all lines - Full Mode protection

Full mode design capable of handling partial lightning currents as well

as allowing continual operation of protected equipment

Repeated protection in lightning intense environments

Low in-line resistance minimises unnecessary reductions in signal strength

2 pin clean end and 3 pin line end to ensure correct insertion

ESP PCB/TN is suitable for telecommunication applications in accordance

with Telcordia and ANSI Standards (see

Application Note AN005

)

Features and benefits

Combined Category D, C, B tested protector (to BS EN 61643) for

“through hole” mounting directly onto the PCB of data

communication, signal or telephone equipment. Available for

working voltages of up to 110 Volts. ESP PCB/TN suitable for

Broadband, POTS, dial-up, T1/E1, lease line and *DSL telephone

applications. For use at boundaries up to LPZ

0

A

to protect against

flashover (typically the service entrance location) through to LPZ 3

to protect sensitive electronic equipment.

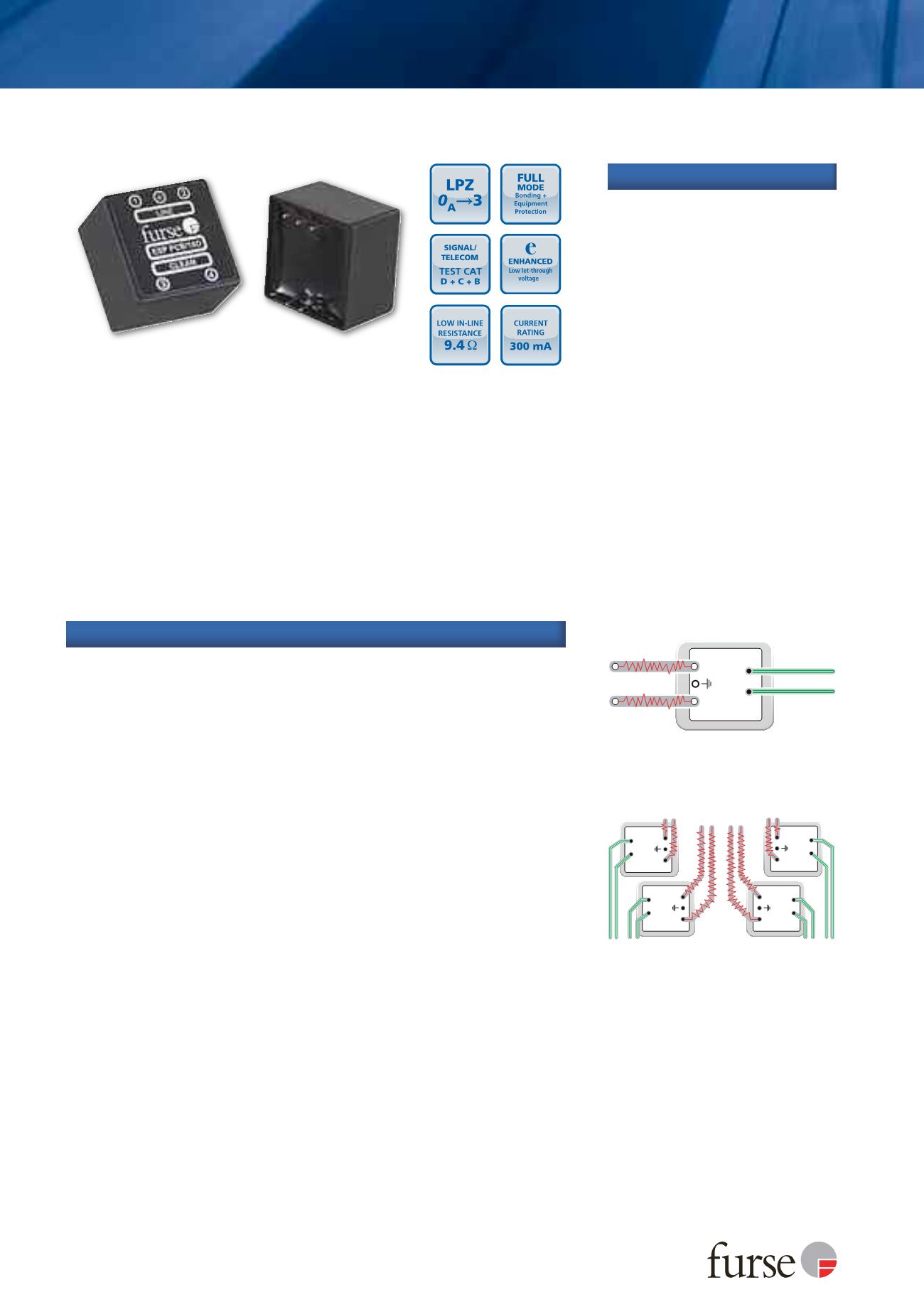

Connect in series, soldering pins

direct onto PCB. Tracks to line and

earth pins should be as wide as

practical (see Furse

Application

Note AN003

).

Dirty (line) tracks should be

routed parallel and as close

together as possible. This should

also be implemented on clean

tracks, however clean tracks

should never be routed close and

parallel to line tracks or dirty

barrier earth connections as

transients can be re-introduced

after the protector due to

electromagnetic coupling.

The use of an earth layer or

plane is highly recommended as

this reduces the electromagnetic

field produced by a transient

discharging to earth considerably,

and hence the chance of the

transient being picked up on

clean tracks.

Installation

Maximum line to clean separation. Large input

tracks and pads (using top and bottom copper

layers). Earth pin is bonded to an earth

layer/plane.

All dirty (line) incoming tracks are separated from

the clean output tracks, individual line and clean

tracks are routed close together. Earth pins are

bonded to an earth layer/plane.

Clean

1 3

4

2

Line

Line

Clean

Clean

3

4

3

4

1

2

1

2

ESP PCB/**

3

4

1

2

ESP PCB/**

1 3

4

2