4/3

Modicon Premium automation

platform

Use of Preventa safety modules

Presentation

(

continued)

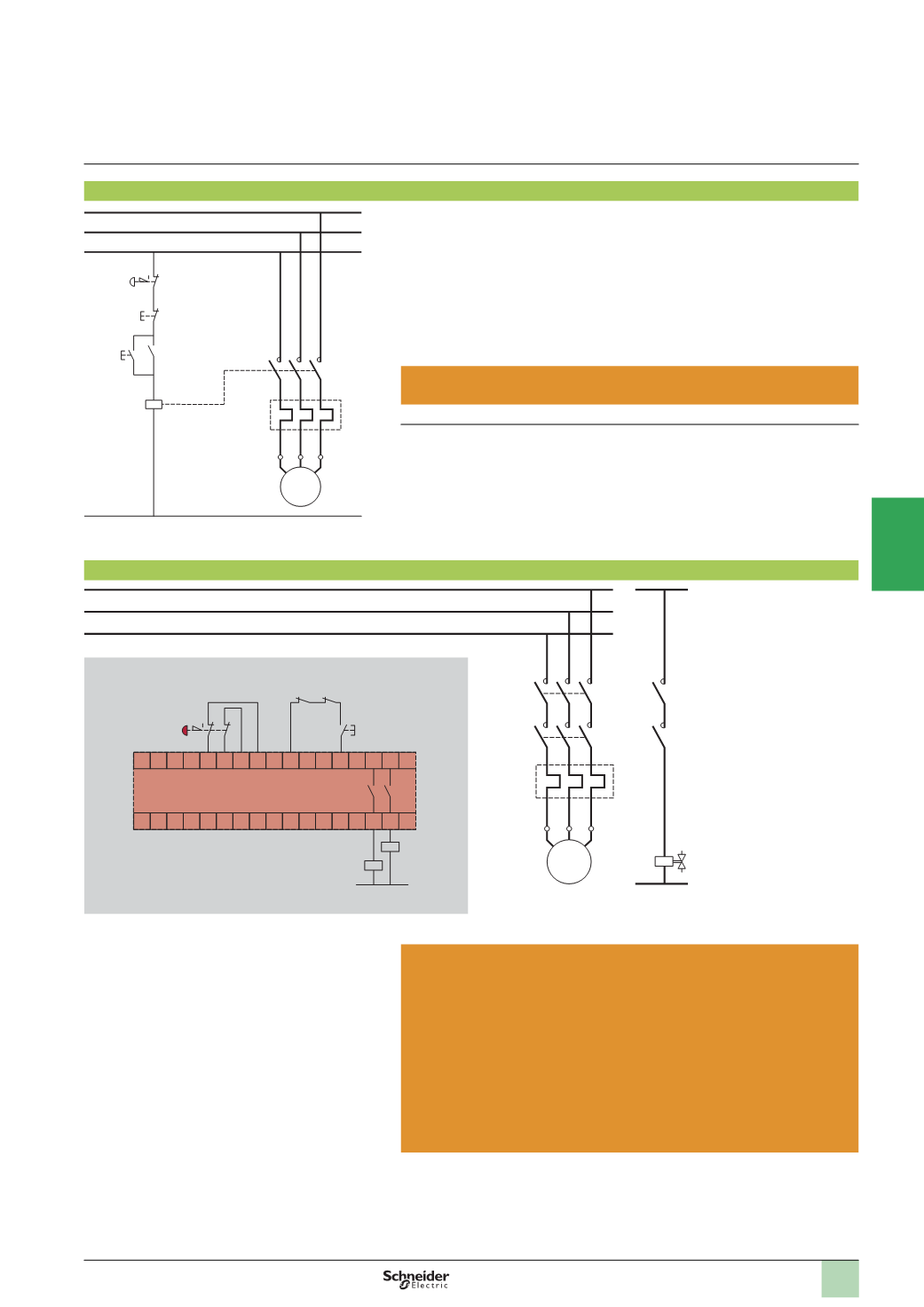

Non-controlled safety systems

M

KM1

KM1

KM1

The control signal from the protection device (emergency stop pushbutton illustrated

to the left) acts directly on the power contactor of the machine.

In this type of scheme, the risks of simple faults are:

b

Emergency stop button being shorted.

b

KM1 contactor sticking.

When the operator presses an emergency stop button, the instruction is not

processed, and another sequence can begin following the emergency stop, despite

the presence of the fault.

In the case of failure, the safety function

(1)

is compromised.

Therefore, a reliable intermediate relay system must be used.

(1)

A safety function is a function whose non-execution or untimely execution results in the

immediate placement of the equipment into a non-hazardous position.

Safety system controlled by a Preventa safety module

KM6

M

KM5

KM6 KM5

KM5

KM6

KM6

KM5

Independent safety circuits

Redundancy

Preventa safety module

Run

Emergency

stop

KM5 and KM6 contactors

with mechnically linked contacts

Feedback loop

Preventa safety modules provide a reliable interposing relay function by

eliminating the risks of:

b

A control circuit fault (inputs).

b

A power circuit fault (outputs).

b

A fault on an internal safety module component.

The safety function remains operative whenever any one of these faults

occur.

Note: For the use of mechanically linked contacts CA2-KN22/KN31, LC1-D09/D18/D25 with

contacts which can be used in the feedback loop, please consult our Customer Care Centre.

Emergency

stop

1

2

3

4

5

6

7

8

9

10