6/45

Software

PL7 software

Process control

Presentation

Process control

Presentation

The process control offer integrated as standard in Premium platforms can be used

to set up and debug machine control-oriented control loops in PL7 Junior/Pro.

User-definable process control functions

TSX P57 2

p

3

M

/

2

p

23

M

/

3

p

3

AM

/

3623

AM

/

453

AM

/

4823

AM

processors make it

possible, depending on the model, to manage between 10 and 20 process control

channels (of 3 loops each).

These channels can be configured to execute algorithms for industrial processes:

b

Cascaded, process, autoselective loops

b

Setpoint programmer

b

Controller with three simple loops

I/O

TSX P57 2

p

3

M

/

2

p

23

M

/

3

p

3

AM

/

3623

AM

/

453

AM

/

4823

AM

processors manage an

entire PLC station comprising racks connected via Bus X.

The I/O interfaces required for process control processing operations are analog or

discrete channels in:

b

In-rack I/O modules

b

TBX, Modicon STB or Momentum distributed I/O modules

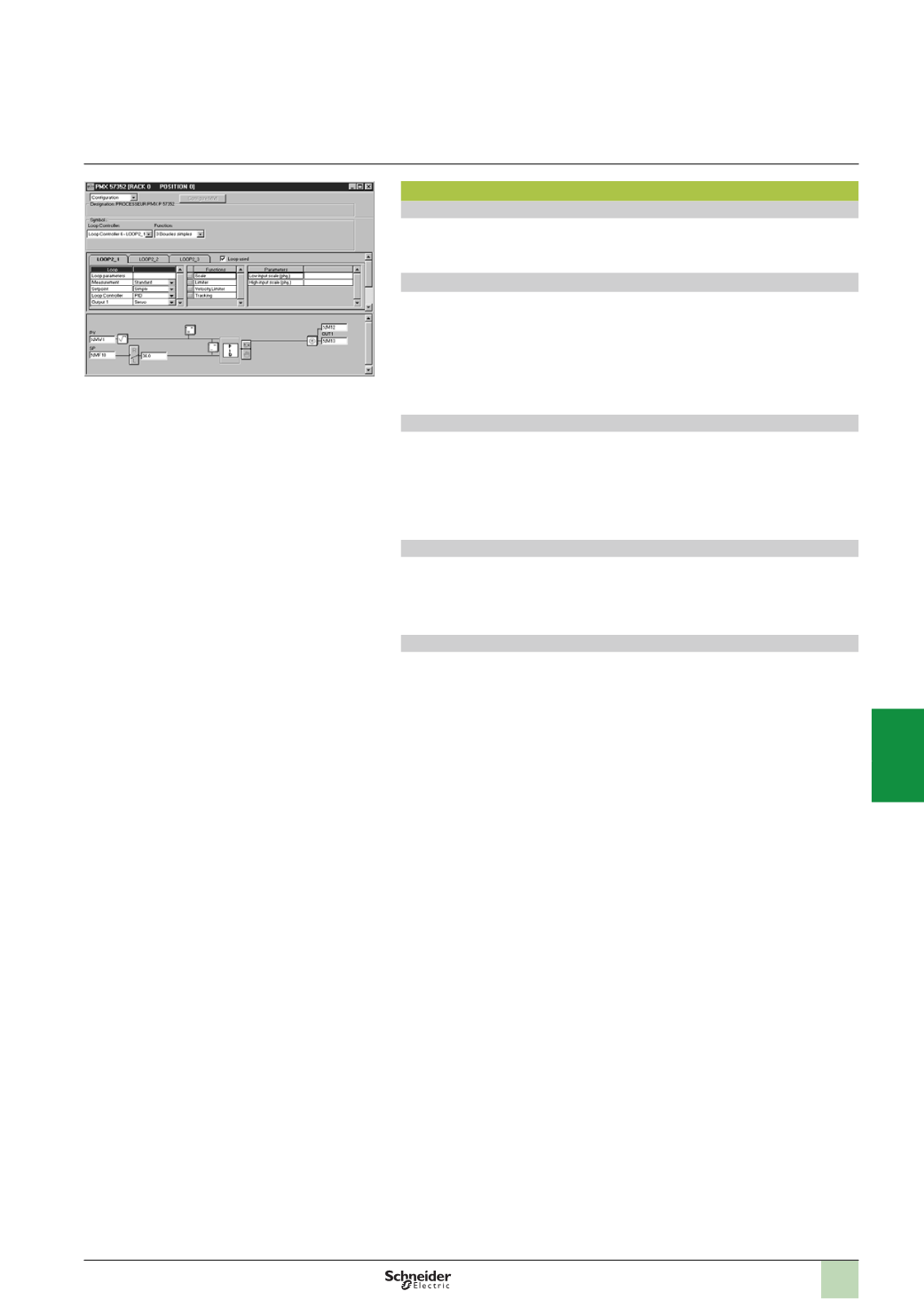

Control loops

Software setup of the control loops is user-definable (Plug and Play technology)

during configuration of the Premium processor.

The user enters information in the predefined loop diagrams which also integrate

management of operating modes and the link with the I/O.

Operator dialogue and control

Magelis operator dialogue terminals have preconfigured screens dedicated to

process control which simplify loop operation and control.

These screens show the controller front panels as well as trending views and

monitoring views.

Configuring process control channels

2

1

3

4

5

6

7

8

9

10