5/120

Profibus DP fieldbus

Profibus DP is one of the most widely used fieldbuses in industry.

Based on a master/slave protocol, only master stations, sometimes called active

stations, have the right to access the bus, with slave, or passive, stations being

limited to responding to interrogations.

Version V0 of Profibus only allows cyclic exchanges with I/O, whereas version V1

offers an acyclic message handling channel which can be used for device adjustment

or diagnostics during operation.

The physical link is a single shielded twisted pair, but numerous interfaces are

available for creating all sorts of topologies - tree, star or ring - including those using

optical fibre or a non-physical link.

Gateways can be used to communicate transparently with Profibus PA, one of the

most commonly used standards in process applications for connecting

instrumentation.

Profibus PA can be used to supply devices across the network and also to install

sensors in potentially explosive zones (ATEX).

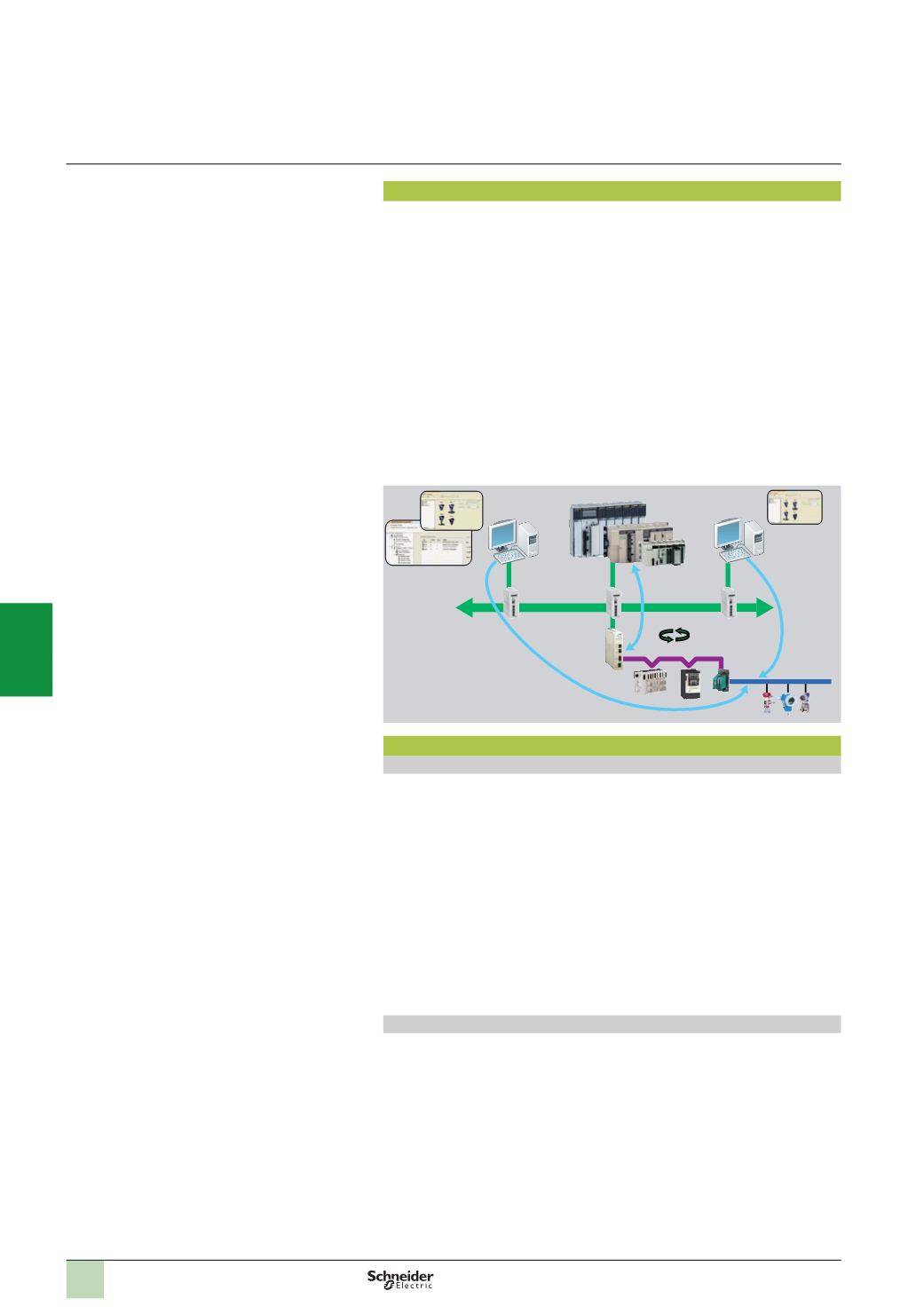

Unity V5.0

PRM master DTM

PRM Com DTM

Ethernet

Profibus PA

PRM

Profibus DP

DP Class 1

Profibus Remote Master (PRM) module

Presentation

The Profibus Remote Master (PRM) module is connected to the Ethernet Modbus

TCP/IP network via its integrated 2-port switch, as close as possible to the process

and the instrumentation.

The PRM module can be used to connect Modicon Quantum, Modicon Premium and

Modicon M340 PLCs to Profibus DP V1 via the I/O scanner function.

Irrespective of the type of PLC, only one product reference is required and setup is

identical, thus reducing training and maintenance costs.

Two versions are available, standard and tropicalized, so as to adapt to any type of

environment.

The PRM module is open to Asset Management tools.

A dedicated communication DTM is supplied with the product, thus allowing any

compatible FDT standard tool to remotely adjust devices on Profibus using Ethernet

(

see page 6/5).

Configuration

From a single Unity tool, the user can create the Profibus configuration, the PLC

application and configure or calibrate devices.

The latter are integrated in the Unity catalogue via their DTMs if they exist, or their

gsd

files.

The I/O scanner configuration is created implicitly in Unity Pro using the Profibus

configuration. The parameters assigned by default guarantee optimized performance,

as well as the consistency of I/O data in the PLC application, irrespective of the PLC

platform.

Similarly, the I/O variables defined and presymbolized in the DTMs can be used

directly in the application. Finally, the screens integrated in Unity Pro, together with

the diagnostic functions integrated in the device DTMs simplify application

maintenance.

Presentation

Modicon Premium automation

platform

Profibus DP V1 and Profibus PA buses

Profibus Remote Master module

2

1

3

4

5

6

7

8

9

10