TECHNICAL INFORMATION

Technical information

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3mm maximum allowable permanent deflection

Point load without

Sub-frame

mm

Point load with

Sub-frame

Plate load without

Sub-frame

Plate load with

Sub-frame

Permanent Set

Underfloor to desk

| 261

Raised floor boxes

Three and four compartment boxes and a

range of grommets that can be configured

to meet client requirements for accessing

multiple services concealed below a raised

floor system.

Technical Specifications

Raised floor boxes are third party tested to

comply with:

BS EN 61534-22:2009

BS EN 60670-1:2005

BS EN 60670-23:2008

BS EN 50085-1:2005

BS EN 50085-2-2:2008

Material

• Lid/trim: flame retardant

polypropylene grey RAL 7011

• Box assembly: galvanised steel

• Load plate: 3mm zinc plated steel

• Accessory plate: galvanised steel

Installation

• Box module has 20 and 25mm

knockouts (pre-wired options available).

• Mounting plates:

3 compartment = 185 x 95mm

4 compartment = 185 x 71mm

• Standard accessory mounting plates

available depending on suitability of

floor box configuration.

• Cable covers protect cables when lid

is closed.

• Detailed installation instructions are

supplied in box.

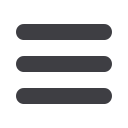

Dimensions

No of

compartments

Nominal

trim size

(L1 x W1)

Cut out dimensions

(L2 x W2)

Accessory Plate

Dimensions

3

357 x 257mm

322 x 222mm

185 x 95mm

4

357 x 257mm

322 x 222mm

185 x 71mm

General tolerance

+3mm

Dimensions

• For dimensions of non standard boxes

and trims, contact Technical Hotline on

+44 (0)1424 856688.

Depth

of void

83mm

40mm

internal

35.6mm

6mm Flooring

Recess

W1

W2

L2

L1

0

0 100 200 300 400 500 600 700 800 900 1000

2

4

6

8

10

12

Load deflection for floor boxes with plate load

andwithout sub-frame

mm

kg

1/4 metric tonne 1/2 metric tonne

Plate load no

sub-frame

6mm maximum allowable

deflection point load

4mm maximum allowable

deflection point load

point load with

sub-frame

plate load with

sub-frame

BS EN 61534-22:2009

BS EN 50085-2-2:2008

point load no

sub-frame

3/4

metric tonne

Care should be taken to ensure that box edges are smoothed and free from burrs.

Carpet tile cut size for lid is 303 x 166mm

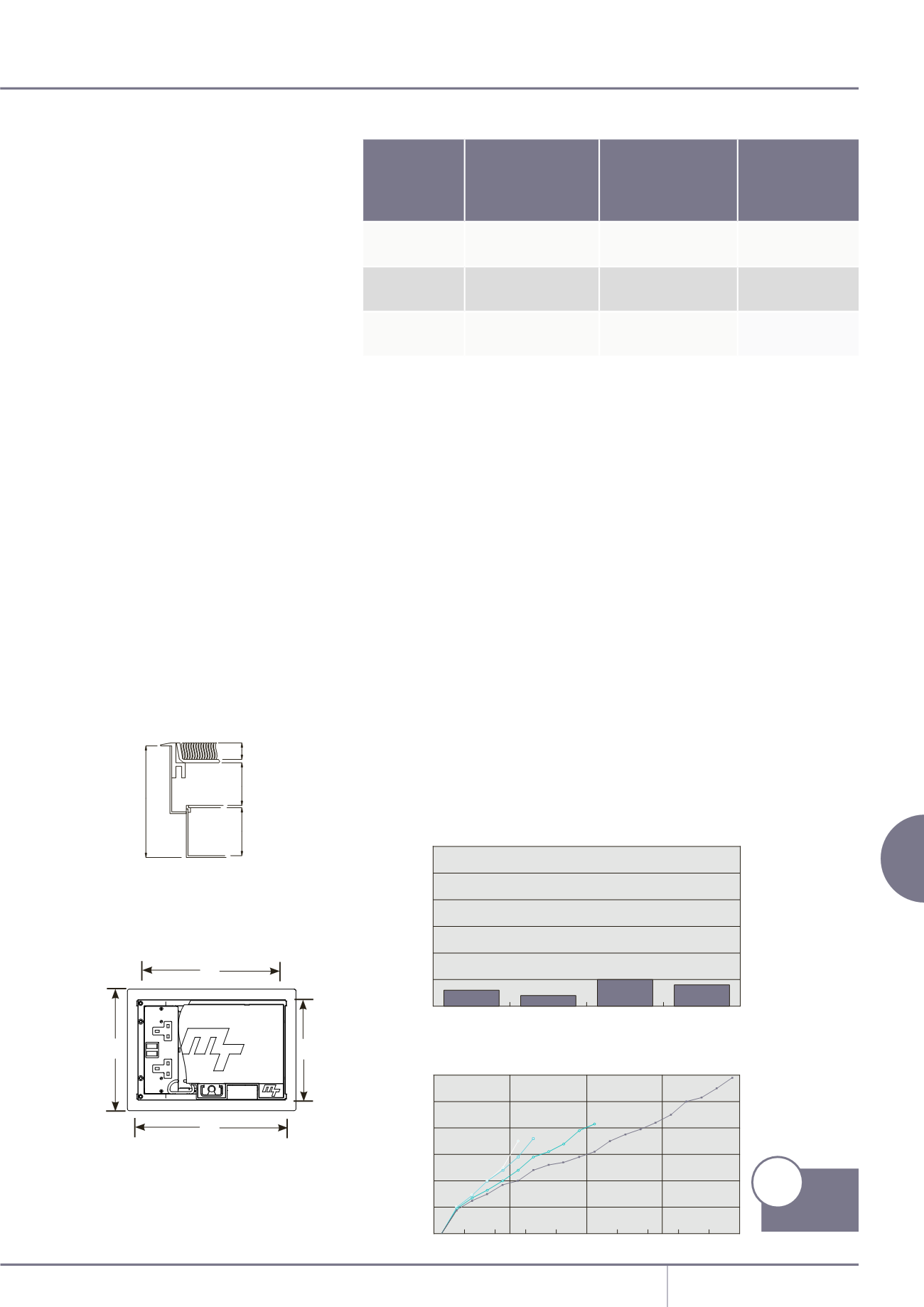

Load Testing

Load testing of floor boxes to:

BS EN 61534-22:2009

BS EN 50085-2-2:2008

The floor boxes have been tested to and

comply with the loading requirements of

the aforementioned standards.

There are two loading criteria for the floor

boxes:

1. A point loading; to simulate foot traffic or

light furniture like a chair leg / caster sitting

on the lid. The maximum permissible

deflection is 6mm (BS EN 61534-22:2009

and BS EN 50085-2-2:2008)

2. A plate loading; to simulate heavy foot

traffic or larger furniture loads. the

maximum permissible deflection is

4mm (BS EN 61534-22:2009) or 6mm

(BS EN 50085-2-2:2008)

Note:

The maximum permissible

permanent deflection after the load has

been removed is 3mm for both standards.

The loading graphs show the deflection

based on floor boxes without and with a

sub-frame. The point loading value is

approaching ¼ of a metric tonne without

sub-frame and reaching ¼ of a metric

tonne with sub-frame. In both cases the

permanent deflection is less than ¼ mm.

For plate loading without sub-frame the

value is approaching ¼ of a metric tonne

with 4mm deflection and ¼

of a metric

tonne with 6mm deflection. With the

sub-frame fitted the loading reaches ¼ of

a metric tonne with 4mm deflection and

½ a metric tonne with 6mm deflection. In

both cases the permanent deflection is

reaching 0.5mm.

Note:

floor boxes fitted with sub-frame

can exceed more than 1 metric tonne

plate load before lid failure. In all tests

(with and without sub-frame) the required

loading was reached without damage to

the plastic trim or compromised the lid.

3

p84

Product

Information