96

Cablelink Plus Screed

Technical

screeded floor systems

customer services +44 (0)1745 532343

Top tips

l

The number and location of boxes will depend on the end user

requirements

l

If the furniture layout is available, a floor box should be considered

for each workstation or desk

l

If the final furniture layout is not available as a general guide the

minmum recommended distribution is one floor box for every

10

m

2

,

and the maximum being one floor box per 4m

2

Cablelink Plus Screed System

Cable Capacity Guide

The cable factor table below is based on the 17th Edition of the IEE Wiring

Regulations and must be regarded only as a guideline. Care should be

taken in selecting adequate trunking sections taking into consideration the

number and size of cables involved and construction of the junction box.

It is recommended that the initial design of trunking installations include

adequate provision for future wiring. To determine the size of the trunking

required, multiply the quantities of each size of conductor and appropriate

factor from Table A and compare the total with the capacity unit figure in

the appropriate Table B.

Table A - Cable Factors

Cable Type

CSA

Cable Factor

Power Cables

PVC Stranded

1.5

mm²

8.6

2.5

mm²

12.6

4

mm²

16.6

6

mm²

21.2

10

mm²

35.3

16

mm²

47.8

25

mm²

73.9

Twin & Earth

2.5

mm²

86

4

mm²

99

6

mm²

148

Data Cables

Cat 5E UTP

5.5

mm dia

30.2

Cat 5E STP

6.0

mm dia

36

Cat 6 UTP

6.5

mm dia

42.2

Cat 6 STP

7.0

mm dia

49

Sample calculation

To estimate the total number of cables that can be accommodated with a

100

x 38mm ducting:

Step 1

Pick the factor from Table B corresponding to 100 x 38 = 1563

Step 2

Select the size of the cable that needs to be pulled through the

trunking and its corresponding factor from Table A

e.g. 4mm

2

stranded = 16.6

Step 3

No. of cables = Value from (Table B / Table A)

e.g. 1563/16.6 = 94 Nos.

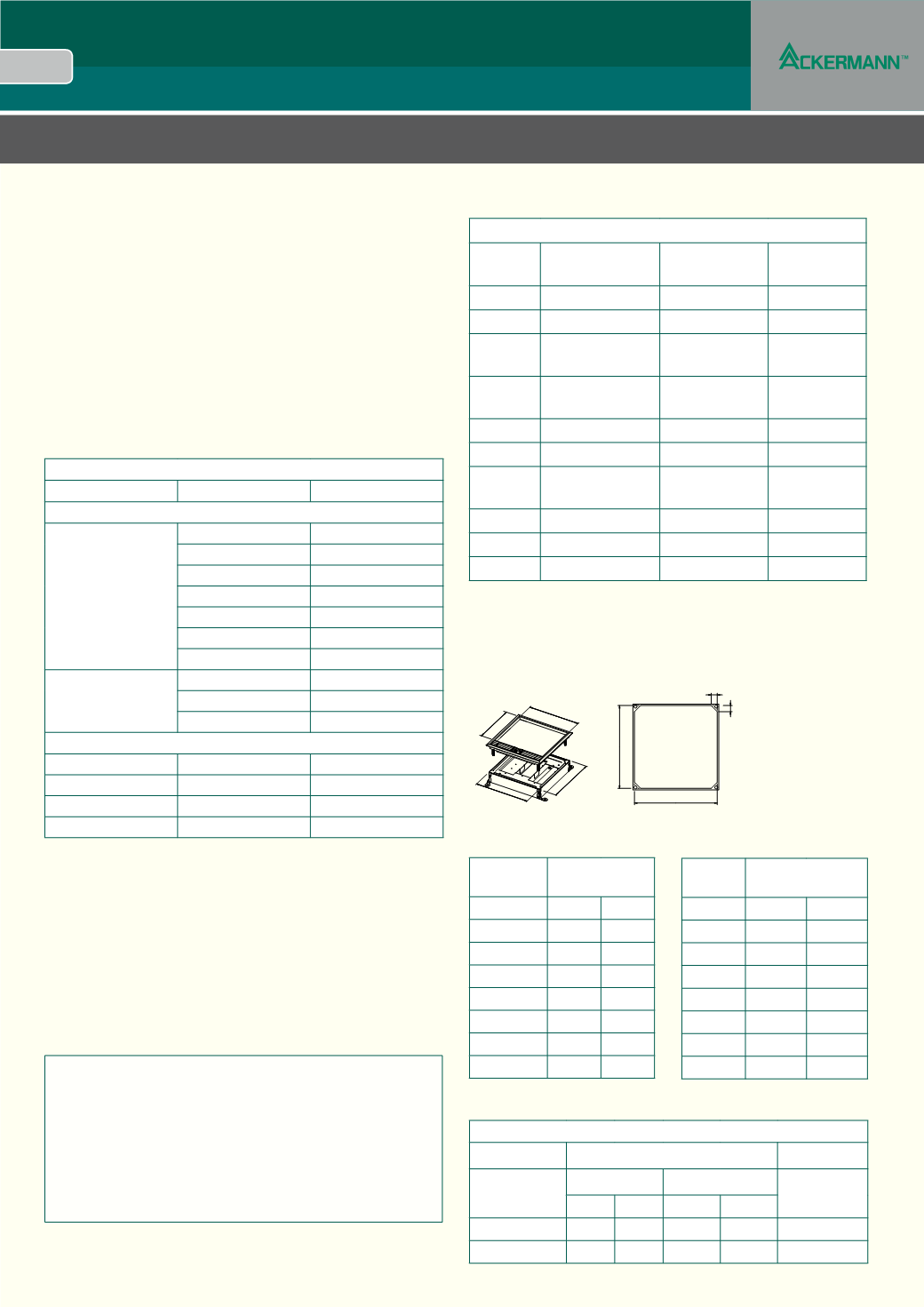

Table B – Metal Screed Ducting Cabling Capacity

Size

(

mm)

Compartment

size

Capacity

100%

Capacity

(45%

fill)

100

x25 100x25 (1 comp) 2205

992

100

x38 100x38 (1 comp) 3474

1563

225

x25 112x25 (2 comp)

75

x25 (3 comp)

2501

1658

1125

746

225

x38 112x25 (2 comp)

75

x38 (3 comp)

3940

2613

1773

1176

250

x25 83x38 (3 comp)

1847

831

250

x38 13x38 (3 comp)

2909

1309

275

x25 137x25 (2 comp)

91

x25 (3 comp)

3066

2035

1380

916

275

x38 91x38 (3 comp)

3206

1443

300

x25 100x25 (3 comp) 2223

1000

300

x38 100x38 (3 comp) 3503

1576

Cablelink Plus Screed System ducting complies with BS EN50085-1: 2005

and draft EN50085 Part 2-2.

The above table gives the available capacity units on 45% factor, applied to

the internal wiring area.

Carpet Cut out Dimensions

The table below shows the sizes required for the carpet lid infill and carpet

tile cut out for the Cablelink Plus Screed Floorboxes.

LID LIST

NUMBER

CARPET LID INFILL

DIMENSIONS (mm)

A

B

CXL100 152

93

CXL200 152 185

CXL265 219 251

CXL340 219 326

CUJL200 188 188

CUJL265 253 253

CUJL240 328 328

Where A is from left to right and B is from back to front.

BASE LIST

NUMBER

BOX CARPET CUT OUT

DIMENSIONS (mm)

C

D

CUB100 100

100

CUB200 200

200

CUB265 265

265

CUB340 340

340

CUJ200 200

200

CUJ265 265

265

CUJ240 340

340

A

B

A

B

C

D

DUCTING CABLE CAPACITY – DATA CABLES

Nominal Cable

Number of Cables

Bend Radius

Diameter mm

2

60

mm Ducting 90mm Ducting (Static on install)

@50% @75% @50% @75%

Cat 5e 5mm 30 45 63

95

20

mm + 10mm

Cat 6 6mm 20 30 44

65

25

mm + 10mm