98

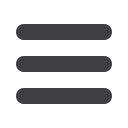

Cablelink Plus Screed

Technical

screeded floor systems

customer services +44 (0)1745 532343

Cablelink Plus Screed System

Installation Guide for Underfloor Duct System

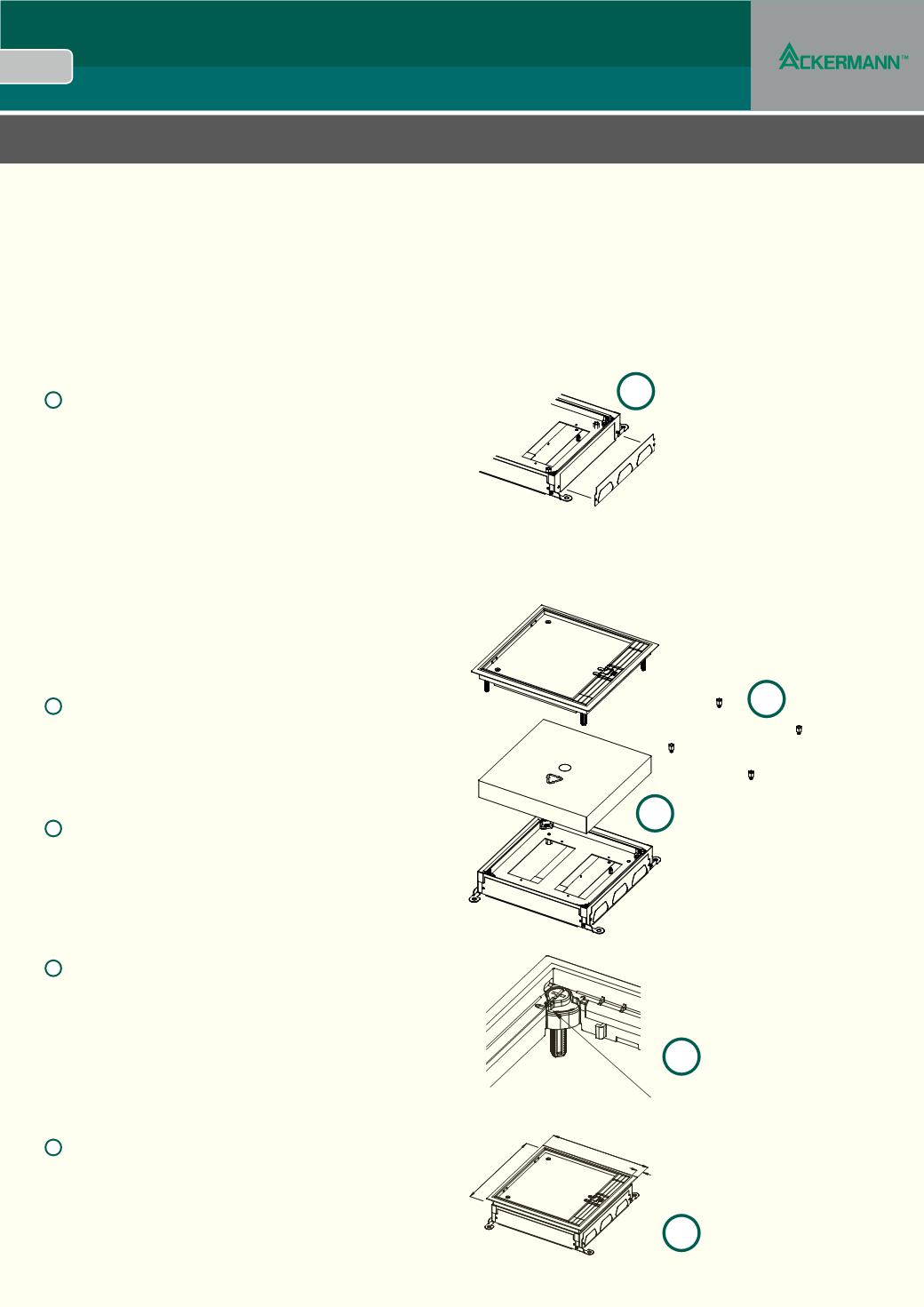

The structural floor slabs on which the underfloor ducts and boxes are to be

laid must be reasonably level and smooth. Humps and protruding cement

must be hacked to level to ensure the ducts being laid will maintain the

minimum screed thickness of 25mm over the ducts. It is recommended that

a layer of green screed be laid on the structural slab beneath the underfloor

ducts to prevent air gaps and vacuum while screeding.

1

The floor slab where junction and service outlet boxes are to be laid

should be marked out. The appropriate duct entry plates should be fastened

to the boxes.

Ducts should be laid in straight lines between points of junction boxes and

parallel to known base lines on each floor. Changes in direction of ducts

should be made with junction boxes.

Use steel fixing clips to secure the ducts on to the floor slab prior to

screeding. The intervals between two saddles should not exceed a maximum

of 2 metres.

All joints in ducts and terminations of ducts in junction boxes / vertical access

boxes should be made water tight with approved type sealing compound.

Precaution should be exercised during construction to prevent damage to

the ducts system and to ensure that the ducts and vertical boxes are free

of water, dirt, debris or any other obstruction which may impede and / or

damage the cables during pulling in.

2

Junction and service outlet boxes should be properly covered with the

disposable lids and taped to ensure no cement gets into the boxes during

screeding.

After screeding the disposable screed cover is removed and the cable

installation can begin.

3

If extra space is required under the accessory mounting tray then height

adjuster kits can be used. The cables can now be installed and the services

terminated.

Note: The bases are supplied with 35mm wiring space, with the option to

reduce to 25mm or increase to 45mm with a height adjustment kit – part

number CUBA-1 or CUBA-2, see page 63

1

2

3

A

B

5

4

4

The frame and lid assembly can now be fitted. Ensure the ratchet

release is set to the lock position and align these with the ratchets in the

aceessory tray.

Ratchet Release

Lock Position

5

Apply gentle pressure until the frame is securely seated in the box and

against the finished floor e.g. carpet or vinyl.