Technical Hotline

+44 (0)1268 563720

687

FLOOR SYSTEMS

SCREEDED

Onix Plus™ Technical

Onix Plus

™

Floorboxes and Power Grommets

Installation of Snorkel Lid

1

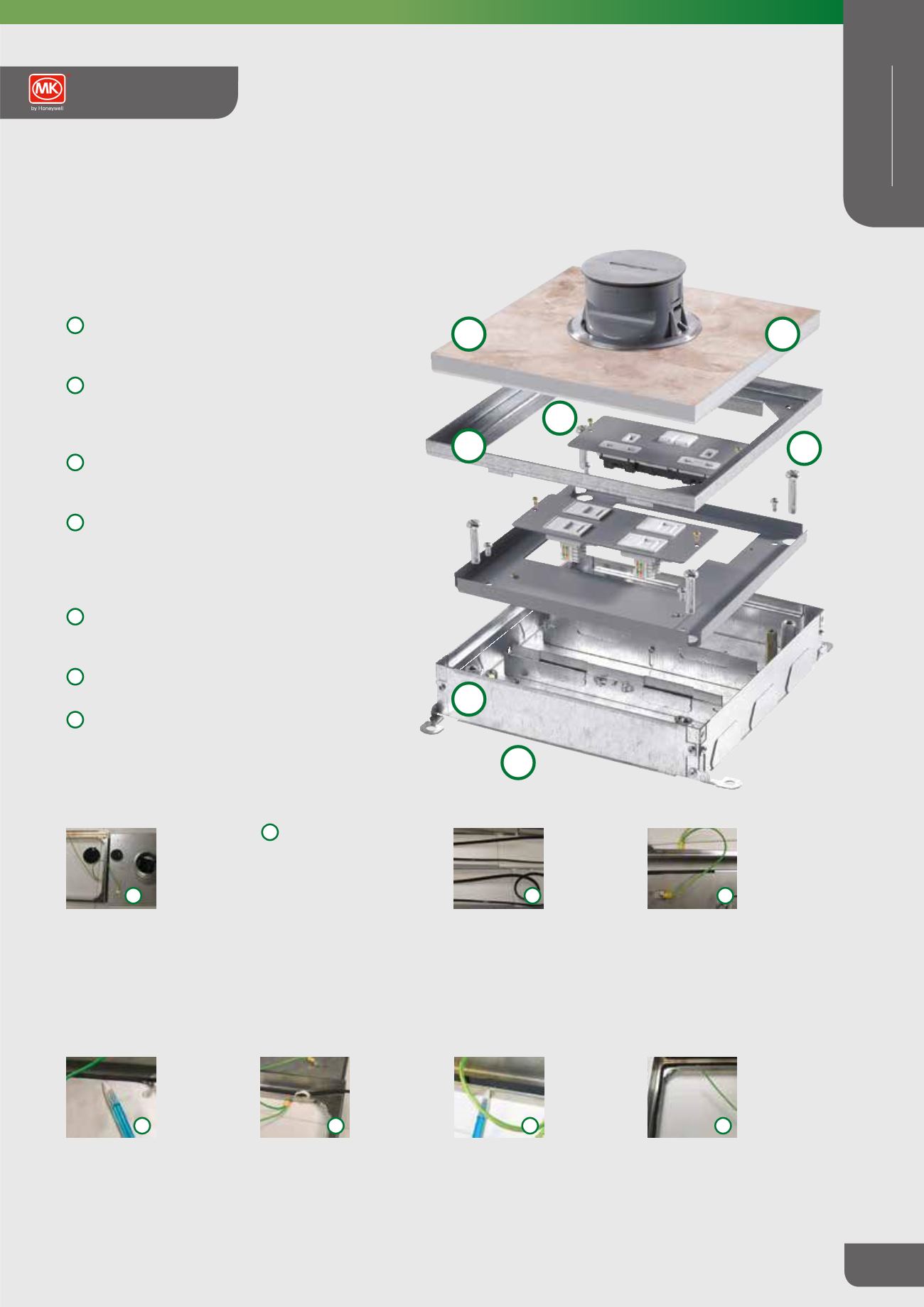

The base unit is fixed to the slab and the ducts or

conduits are fed into the base using the appropriate

side entry plate.

2

The disposable screed cover is fitted to prevent the

ingress of screed through the top. All areas of the box

which may be susceptible to screed ingress should be

sealed.

3

The Lid frame should be assembled and fitted after

the disposable screed lid has been removed and the

gasket can now be fitted.

4

The lid is supplied with an earth lead and must be

bonded to earth for all power applications. As the lid

is only installed when the floor covering is laid there

is less chance the surface finish of the lid will be

damaged.

5

A floor covering insert is required for the lid recess.

The dimensions for the insert are given in the Lid

Recess Dimensions section see page 685.

6

Sealing compounds are required for products that are

for use in wet wash environments.

7

The bases are supplied with 35mm wiring space,

but with the option to reduce to 25mm or increase to

45mm with the Cuba-1 height adjustment kit.

How to Install the Gasket

1

2

4

5

3

7

6

Identify the

gaskets

The wider

gasket is

used in the

frame and the narrower gasket

is used on the lid. The gaskets

are designed to sit next to one

another, not one on top of the

other.

Ensure gasket is clean

Ensure both lid and frame are

dry, clean and free from oily

deposits and debris such as

grout and screed.

If replacing the gaskets ensure

all traces of existing gasket

and adhesive have been

removed. An alcohol wipe

will aid the removal of the

adhesive backing.

Ensure

gasket is

straight

The gasket

must have

no twists in it. Any twists will

result in the gasket not fitting

and functioning correctly.

2

Fitting lid

gasket

Start the lid

gasket on the

underside of

the lid as close to the outer edge

as possible, approximately half

way along the length. Ensure

the gasket runs underneath the

Earth bonding cable. Do not run

the gasket past the first corner

at this stage.

3

7

1

3

4

Identify the

gaskets

Butt the

other end of

the gasket to

the start to ensure a good join.

This also ensures the gasket is

not stretched unduly.

Continue fitting the gasket

around the edge of the lid

keeping the corners as close to

90° as possible, until complete.

5

Fitting

frame

gasket

Start the

frame gasket

as close to the inner edge as

possible, approximately half

way along the length. Ensure

the gasket runs underneath

the Earth bonding cable. Do

not run the gasket past the first

corner at this stage.

6

Fitting

frame

gasket

Butt the end

of the gasket

to the start to ensure a good

join. This also ensures the

gasket is not stretched unduly.

7

Fitting

frame

gasket

Continue

fitting gasket

around the inner edge of the

frame, ensuring the gasket

runs to the outside of the

screw hole, until complete.

8