mkelectric.co.uk

mkelectric.co.uk

666

CABLE MANAGEMENT

PERIMETER AND

DISTRIBUTION

For a full range of corresponding products,

see pages 350-354 in the product selector.

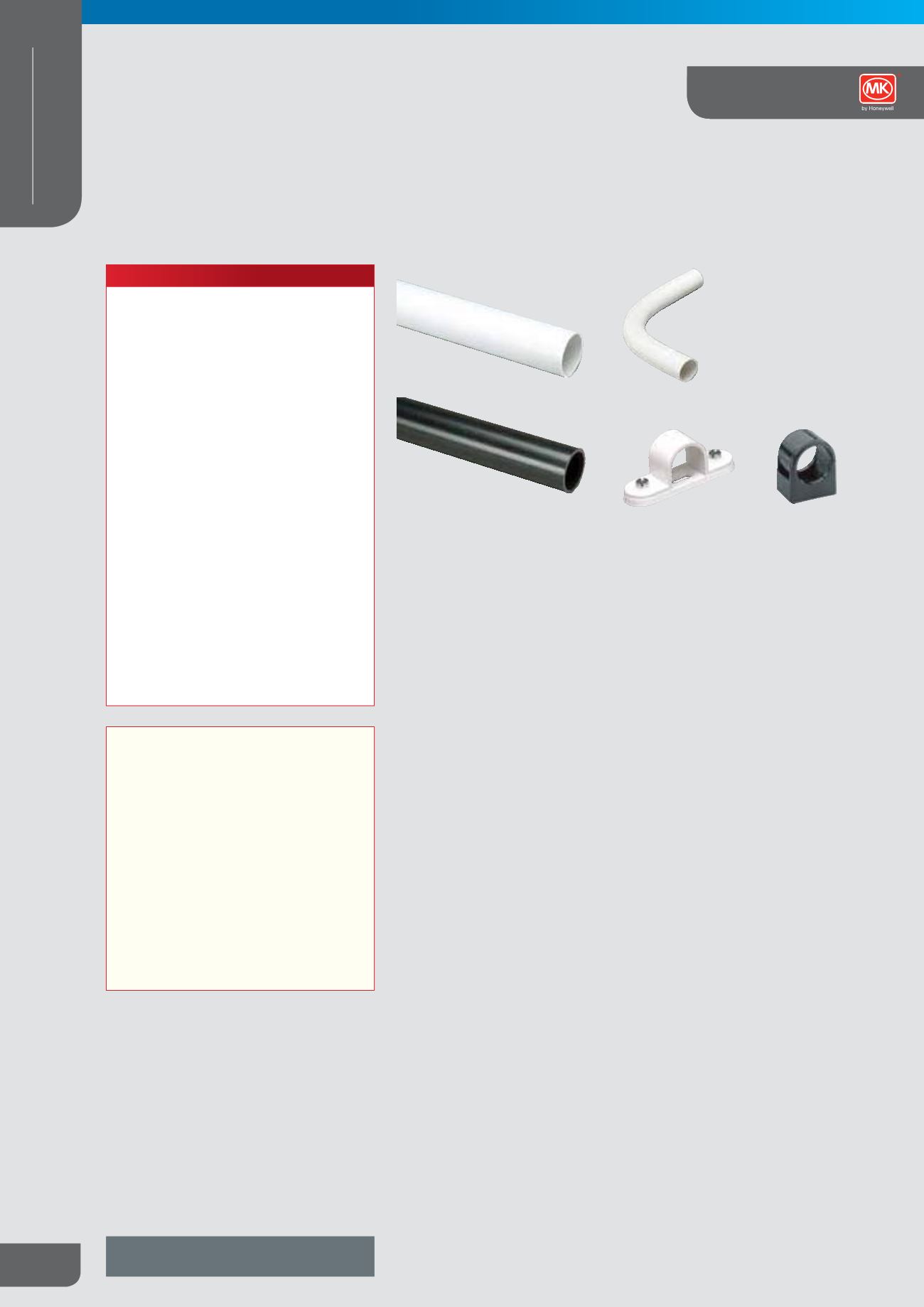

Egatube Conduit

Technical

Conduit and fittings

Description

Egatube high impact PVCu conduit offers a cost effective solution for both new and

refurbishment contracts.

The conduit is available in oval sections (6 sizes), in 2 grades of round section

(6 sizes of each) and as a flexible corrugated version (3 sizes).

The wide range of fittings and ancillary products means that almost any installation

can be specified for with confidence.

Egatube conduits are light in weight, the smaller sizes can be bent cold and they

can easily be cut using a hacksaw or Egasnips. This means that installation can be

50% quicker than using steel. Repairs and alterations are also simpler and quicker

to make.

FEATURES

l

Wide range of sections and sizes

l

Oval, round and corrugated sections are

compatible

l

Simple and fast installation

l

Very wide range of components

maximises versatility of application

l

Very durable and impact resistant

l

2 grades of round conduit to suit various

site conditions

l

All extrusions manufactured from 100%

recycled material*

* Based on 2014 consumption

TECHNICAL SPECIFICATION

MATERIALS

PVCu materials used in the manufacture of MK

products are self extinguishing non-flame propagating

in accordance with BS 4678 Part 4.

Extrusion material has been tested by a UKAS

accredited laboratory in accordance with the

requirements of BS 476 Part 7 and has achieved a

Class 1Y.

Moulding material has been tested by a UKAS

accredited laboratory and conforms with IEC 695-2-1

at a severity of 650°C

IET WIRING REGULATIONS

Designed and manufactured to comply in all respects

with BS 7671:2008 (IET Wiring Regulations 17th

Edition: 2008)

QUALITY ASSURANCE

The system is manufactured to BS EN ISO 9001

Classifications to BS EN 61389-1:2008 and

BS EN 61386-21:2004 available on request

521.11.201 WIRING SYSTEMS IN ESCAPE ROUTES

Conduit systems

– MK recommends the usage

of standard metallic saddles and bars when using

conduit in escape routes

Trunking systems

– MK recommends the use of

existing metallic cable retention systems when using

trunking in escape routes