Technical Hotline

+44 (0)1268 563720

671

CABLE MANAGEMENT

PERIMETER AND

DISTRIBUTION

Egatube Conduit

Technical

Fixing

Egatube round conduit is fixed in the normal way with saddles

or clips. (Various types of saddles are available). The distance

between saddles should not exceed that stated in the following

table, or less in hot temperatures.

NOMINAL CONDUIT

SIZE (mm)

MAXIMUM DISTANCE BETWEEN

SUPPORTS (M)

HORIZONTAL

VERTICAL

Not exceeding 16

0.75

1.00

Exceeding 16 but not

exceeding 25

1.5

1.75

Exceeding 25 but not

exceeding 40

1.75

2.00

Exceeding 40

2.00

2.00

It is recommended that all boxes be fixed first wherever

practicable, using the two fixing holes provided in circular boxes.

Lines may then be struck for the saddle run and the saddles

should be fixed 225mm on either side of bend or boxes. The

tubing may then be ‘sprung’ into the box spouts. It will be noted

that the saddles are designed to be a sliding fit on the conduit

and it is important to see that all fixings should be sliding fits

(see Expansion).

Expansion

A rise in temperature of 25°C would cause an increase of 5mm

in a 3 metre length of conduit. This may be ignored in flush work

where the tube is bonded to the concrete or plaster.

In surface work, however, precautions must be taken or expansion

will cause the tube to bow, although where bends and sets are

close together these take up any expansion. Where long straight

runs occur in conditions of varying temperatures, care must be

taken to overcome problems by using expansion couplers. These

are couplers of double normal length with a shoulder formed

19mm from one end. Conduit is secured into this end of about

75mm long which is a sliding fit over the other conduit. The other

conduit is inserted about 50mm into the coupler leaving it free

to move 25mm in either direction, which is ample for even the

greatest extremes of temperature. For straight runs it is advisable

to use an expansion coupling every 6 metres.

Conduit and fittings

Adhesives

Egaweld Plus

Waterproof for making watertight joints between PVC conduit,

trunking and fittings.

A statement regarding COSHH regulations is available on the MK

website –

www.mkelectric.co.ukLight fittings

When considering the use of totally enclosed lighting fittings,

remember that the IET Wiring Regulations restrict the use of

PVCu boxes to loads of 3 kg and a temperature of 60°C. When

conditions in excess of these figures are anticipated, the use of

either the heat resistant boxes or conduit boxes suffixed ‘EL’ are

recommended.

The “EL” conduit boxes will support a load of up to 10 kgs at 60°C.

Fittings

A wide range of fittings are available, see Product Selector

for details.

Bending

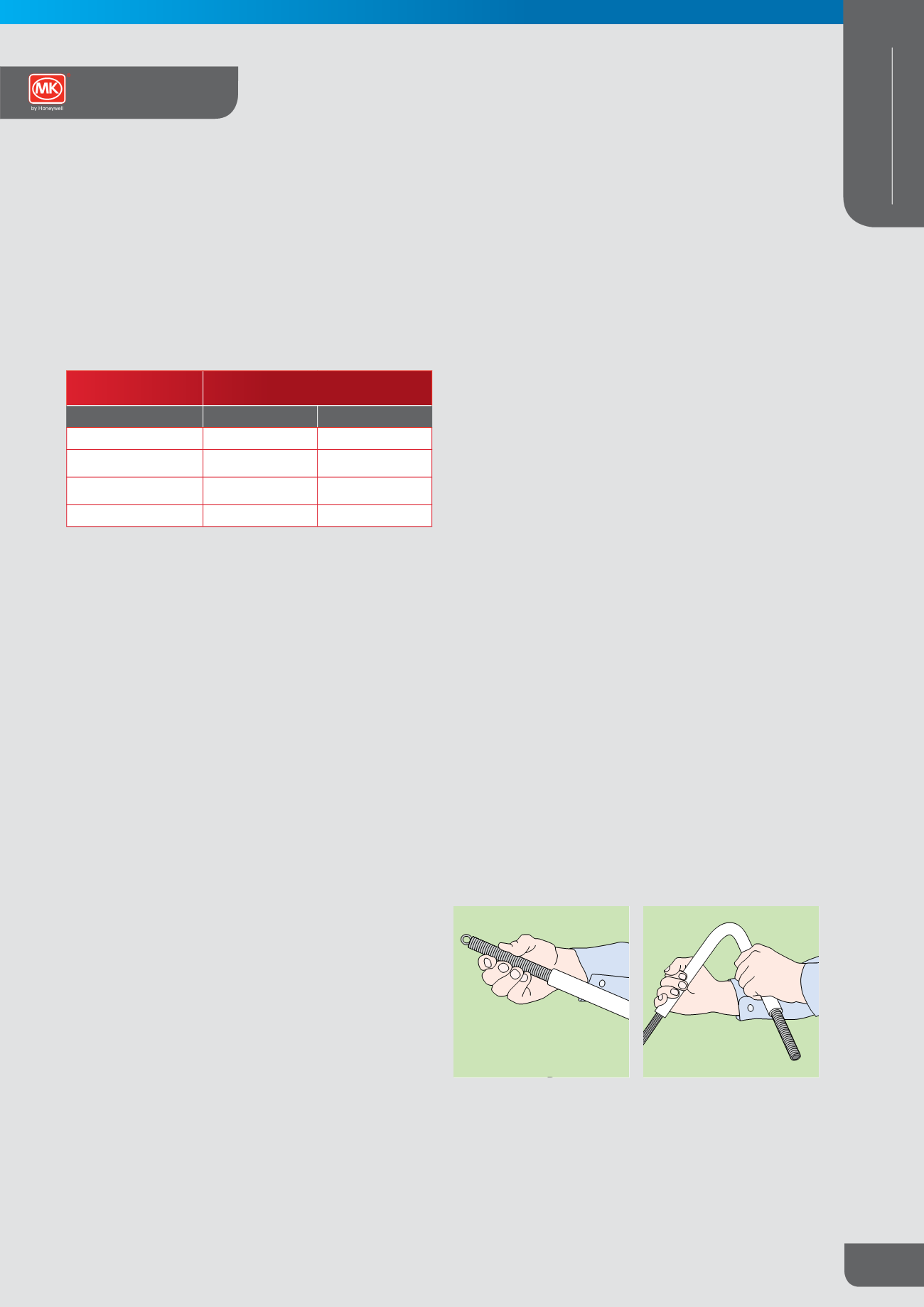

To bend circular conduit, insert the appropriate spring. The

spring has an “eye” formed on one end, to which a cord should

be attached in order to withdraw the spring. The bend is then

made by hand. Twice the angle required should be bent and

the tube then allowed to ease back to the desired position. Do

not attempt to force the bend back with the spring inserted, as

this action will damage the spring. When withdrawing the spring

it is suggested that it be twisted in an anti-clockwise direction

thus reducing the diameter of the spring and providing easy

withdrawal. It is important to use the correct size spring. In cold

weather it may be necessary to warm the tube slightly at the

point where the bend is to be made. Always saddle the tubing as

quickly as possible after bending.