Technical Hotline

+44 (0)1268 563720

677

FLOOR SYSTEMS

RAISED

For a full range of corresponding products,

see pages 377-381 in the product selector.

Cablelink Plus Modular

Technical

Cablelink Plus Modular Floorbox

Load Testing

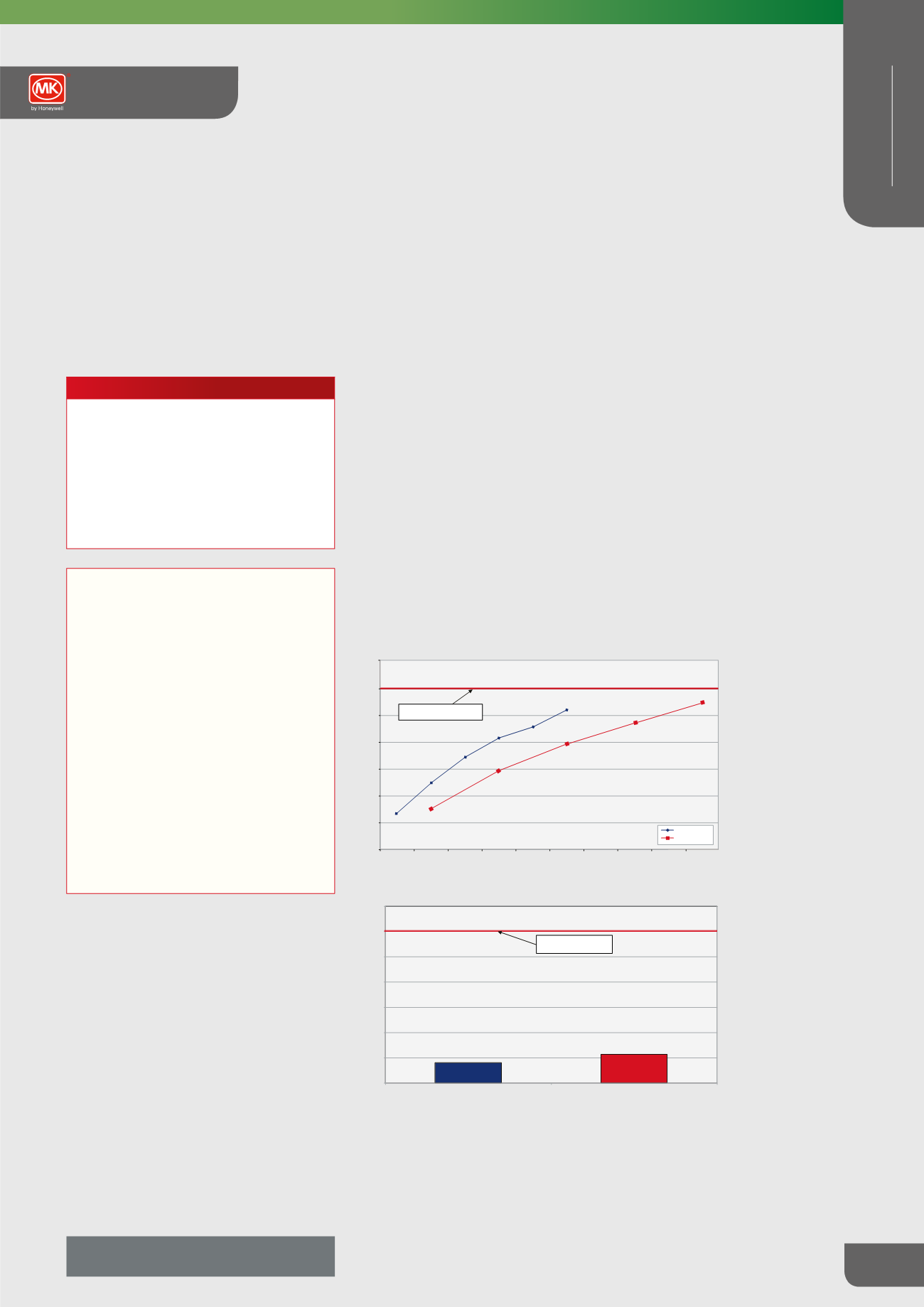

Load Testing of floorboxes to BS EN 50085 Part 2-2 (Clauses 10.5.103 and 10.5.104).

The floorboxes have been tested to and comply with the loading requirements of BS

EN 50085 Part 2-2 (Cable trunking systems and cable ducting systems for electrical

installations Part 2-2: Particular requirements for cable trunking systems and cable

ducting systems intended for mounting underfloor, flushfloor, or onfloor).

There are two loading criteria for the floorboxes - one with a point loading to replicate

foot traffic for example, and the other, with a large plate to replicate hand trucks / trollies

and heavier larger loads. For both loading criteria the maximum allowable deflection

under load is 6mm and the maximum permanent deflection after the load has been

removed is 3mm. The loading position is the centre of the lid.

The Lid Deflection (loading) graph shows that the maximum point loading

classification achieved is 3kN and the maximum large plate loading classification

achieved is 5kN.

The Permanent Deflection graph shows the permanent deflection from the test

wheel loading at 3kN is 0.55mm and large plate loading at 5kN is 0.4mm.

This is well within the maximum allowable deflection of 3.0mm.

Lid Deflection – Cablelink Plus 265 x 265mm Frame Assembly

0

1

2

3

4

5

6

0.5

1

1.5

2

2.5

3

3.5

4

Load (kN)

Deflection under Load (mm)

Point Loading

Plate Loading

MaximumAllowableDeflection

Under Load (6mm)

7

4.5

5

Permanent Deflection After Removal of Load – Cablelink Plus 265 x 265mm Frame

0

0.5

1

1.5

2

2.5

3

3.5

Large Plate Load (5kN)

Point Load (3kN)

Permanent Deflection (mm)

MaximumAllowable

PermanentDeflection (3mm)

Standards and Approvals

The Cablelink Plus Modular floorbox supports

compliance with the latest edition of the IET

Wiring Regulations (BS 7671) and to

BS EN 50085 Part 1 and BS EN 50085 Part 2-2.

TECHNICAL SPECIFICATION

MATERIALS

PLASTIC COMPONENTS

Manufactured from UL94 V2 rated nylon.

METAL COMPONENTS

Manufactured from pre-galvanised steel.

Accessory plates are powdercoated or colour coated.

RAL COLOURS

Grey (GRY) = RAL 7011

Feature benefits

l

Tested to EN 50085-2-2 to accept 5000N load

l

Quick release blades ensure a fast and simple

installation

l

Designed to support Cat 6 & Cat 7 structured

cabling systems

l

Self closing lid in accordance with IEC 61534-22

l

Wide range of power and data accessories

available to meet all requirements

l

Quality, reliability and safety come as standard

l

Provision of RCD protection supports

compliance with the 17th Edition Wiring

Regulations

l

5 year guarantee

Installation

Cablelink Plus Modular boxes should not be

installed in the following situations:

l

Where protruding electrical cables are likely

to cause a safety hazard

l

In passageways, especially where trolleys or

other vehicles may be used

l

On escape routes, as this may impede the

evacuation of the occupants from the building

l

Where the cleaning methods employed result

in the formation of pools of liquid or soaking

of the floor surface

l

Desks, chairs, shelving, filing cabinets should

not be positioned on the floorbox as this will

interfere with opening the lid