Technical Hotline

+44 (0)1268 563720

679

FLOOR SYSTEMS

RAISED

Cablelink Plus Modular

Technical

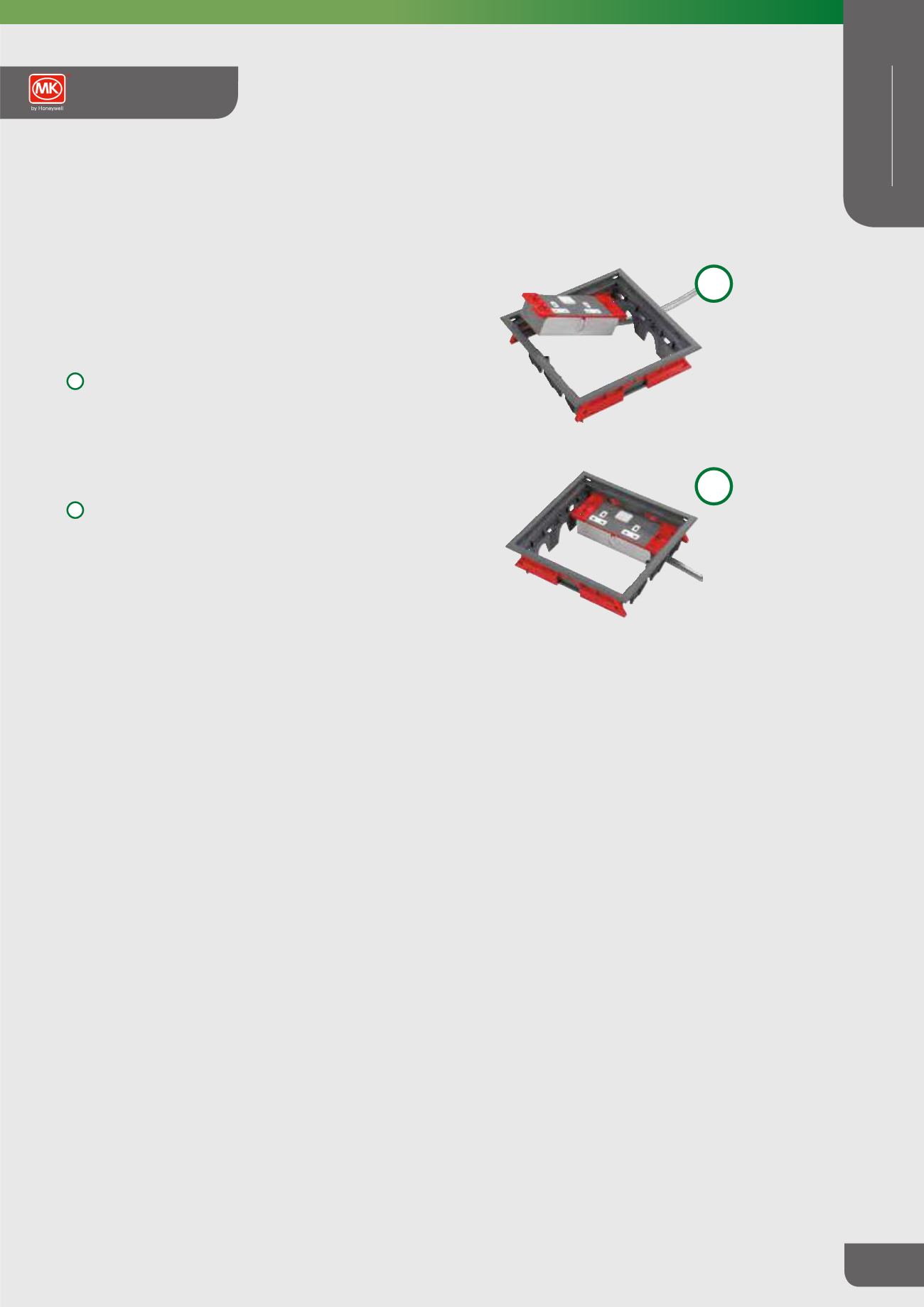

Installing Modules into the Cablelink Plus

Modular Floorbox

To install a module into the Cablelink Plus Modular floorbox, firstly

ensure the sliding bracket is pushed towards the centre of the

module.

1

Lower the opposite end into the box and push the tab firmly

into the slot in the ladder at the height the module should be

positioned.

The other end is then lowered down so that the tab on the sliding

bracket is level with the same slot on the other side of the frame.

2

Holding the module with the built in handles, the sliding

bracket is then pushed outwards so that the tab engages with the

correct slot.

A screw is then used to fix the sliding bracket in place.

Fix the retaining clips to each end of each module and frame.

The module is now secure. The procedure is reversed in order to

remove a module.

Clean Earth Sockets

Clean Earth Sockets allow the designer and installer to introduce a

protective conductor connecting sensitive equipment i.e. a computer,

directly to the main earth.

This reduces the possibility of ‘noise’ occurring on the protective

conductor through induced voltages from other equipment, and hence

can have benefits in maintaining data and data transmission integrity.

Earthing on Data modules for Modular Raised

Earthing studs are provided on all Unserviced data modules to

enable a reliable connection to earth to be made. Earthing Kit CX-10

is recommended for use to ensure the earthing cable is connected

correctly.

1

2

†

In the 17th Edition of the IEE Wiring Regulations, these requirements are found in Regulation 543.7.

Cablelink Plus Modular Floorbox

Dual Earth Sockets and High integrity Earthing

†

Modern offices, schools, universities, laboratories etc, are heavy

users of IT, computing and electronic equipment. As most of this

equipment is fitted with a filter mechanism to protect data and data

transmission against RFI and power surges, small earth leakages

emanating from this equipment introduces a current onto the

Circuit Protective Conductor (CPC) effectively turning this into a

functional earth.

Should the CPC be broken, any equipment downstream of the

break is no longer connected to earth. If a fault now occurs in this

equipment, the CPC could rise to the mains potential and the fault

transferred to other equipment on the circuit. The implicit risks to

equipment, data and most importantly users in this situation are

dealt with in the 17th Edition of the IET Wiring Regulations

†

, and

have led MK Electric to introduce Dual Earth Sockets.

Dual Earth Sockets allow the designer and installer to maintain the

earth integrity of the system, in accordance with the 17th Edition

of the IET Wiring Regulations

†

is intended to maintain at all times

the CPC to ensure safety.