9/52

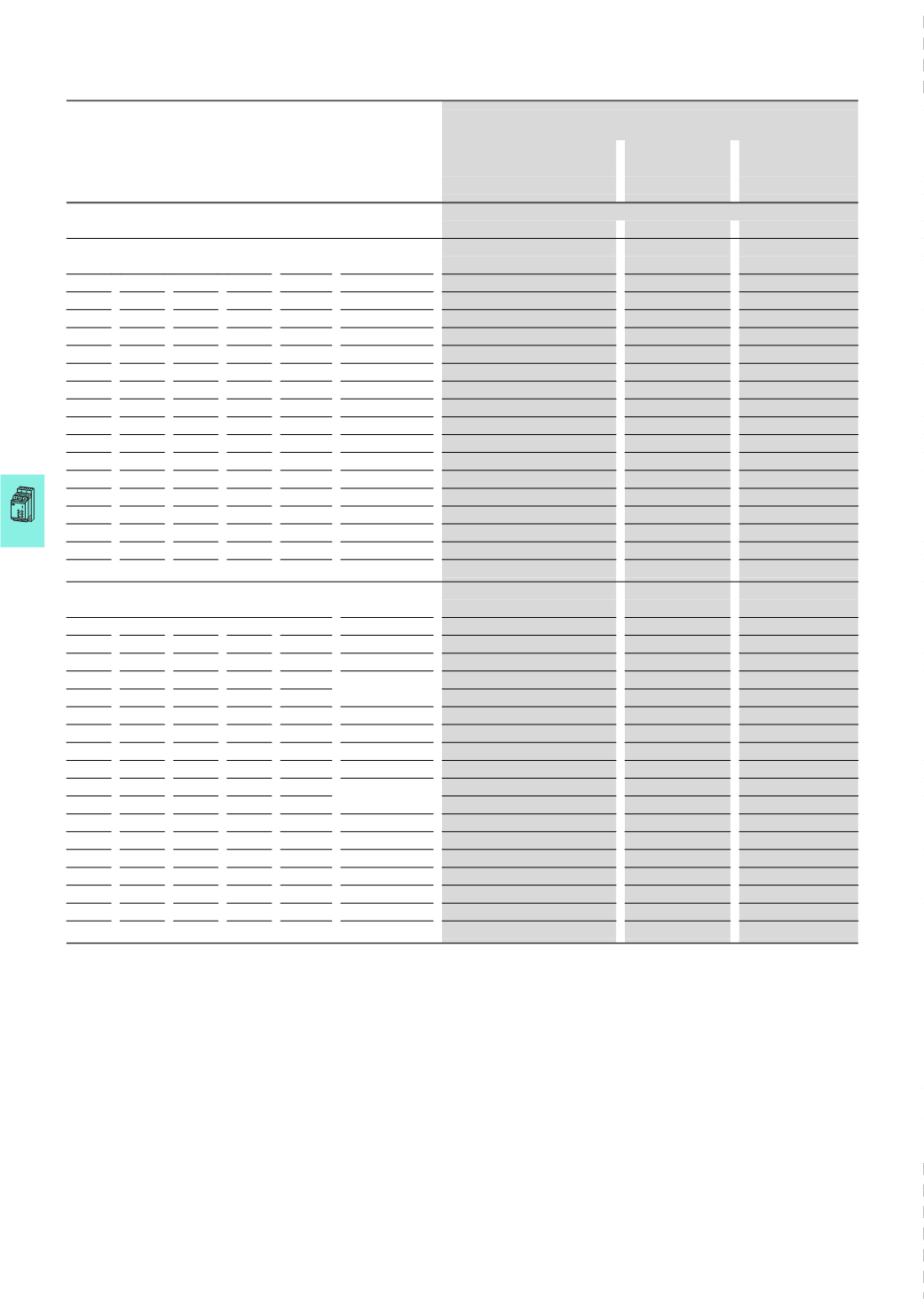

DM4 soft starters

Long start-up time

2010

CA08103002Z-EN

www.eaton.comLong start-up time

Assigned motor

rating at

Rated operational current

2)

Part no.

1)

Soft starters

Soft starter function

400

V 480 V Device Motor

Cable

3)

Cable protection

Mains contactor

(

optional)

4)

Overload relay

5)7)

P

P

I

e

I

e

I

e 2)

kW HP

A

A

A

Soft starters for three-phase mains connection, long start-up time

Tripping class CLASS 10 (15 s, 3.5 x I

e

)

"

In-line" terminal type

(

upstream of load, standard)

7.5

10

22

15.2

21

DM4-340-11K

PKM0-25 (+ CL-PKZ0)

DILM17

ZB32-16 (+ZB32-XEZ)

11

15

30

21.7

31

DM4-340-15K

PKM0-32 (+ CL-PKZ0)

DILM25

ZB32-24 (+ZB32-XEZ)

15

20

44

29.3

41

DM4-340-22K

PKZM4-58 (+ CL-PKZ0)

DILM32

ZB32-32 (+ZB32-XEZ)

22

30

59

41

58

DM4-340-30K

PKZM4-58 (+ CL-PKZ0)

DILM50

ZB65-57 (+ZB65-XEZ)

30

40

72

55

78

DM4-340-37K

NZMN1-ME90

6)

DILM65

ZB65-65 (+ZB65-XEZ)

37

50

85

68

96

DM4-340-45K

NZMN1-ME90

6)

DILM80

ZEV + ZEV-XSW-145

45

60

105

81

114

DM4-340-55K

NZMN1-ME90

6)

DILM95

ZEV + ZEV-XSW-145

55

75

146

99

140

DM4-340-75K

NZMN2-ME140

6)

DILM115

ZEV + ZEV-XSW-145

75

100

174

134

189

DM4-340-90K

NZMN2-ME140

6)

DILM150

ZEV + ZEV-XSW-145

90

125

202

161

227

DM4-340-110K NZMN2-ME220

6)

DILM185

ZEV + ZEV-XSW-820

110

150

242

196

276

DM4-340-132K NZMN2-ME220

6)

DILM225

ZEV + ZEV-XSW-820

132

200

300

231

326

DM4-340-160K NZMN3-ME350

6)

DILM250

ZEV + ZEV-XSW-820

160

250

370

279

393

DM4-340-200K NZMN3-ME350

6)

DILM300

ZEV + ZEV-XSW-820

200

300

500

349

492

DM4-340-250K NZMN3-ME350

6)

DILM400

ZEV + ZEV-XSW-820

250

400

600

437

616

DM4-340-315K NZMN3-ME450

6)

DILM500

ZEV + ZEV-XSW-820

315

500

750

544

767

DM4-340-400K NZMN3-ME550

6)

DILM580

ZEV + ZEV-XSW-820

400

600

900

683

963

DM4-340-500K NZMN3-ME875

6)

DILM750

ZEV + ZEV-XSW-820

"

In-Delta" terminal type

(

in series with each motor winding)

11

15

16

21.7

31

DM4-340-7K5

PKM0-32 (+ CL-PKZ0)

DILM25

ZEV + ZEV-XSW-25

15

20

30

29.3

41

DM4-340-15K

PKZM4-58 (+ CL-PKZ0)

DILM32

ZEV + ZEV-XSW-65

22

25

44

41

58

DM4-340-22K

PKZM4-58 (+ CL-PKZ0)

DILM50

ZEV + ZEV-XSW-65

30

30

59

55

78

DM4-340-30K

NZMN1-ME90

6)

DILM65

ZEV + ZEV-XSW-65

37

40

59

68

96

NZMN1-ME90

6)

DILM80

ZEV + ZEV-XSW-145

45

50

72

81

114

DM4-340-37K

NZMN1-ME90

6)

DILM95

ZEV + ZEV-XSW-145

55

60

85

99

140

DM4-340-45K

NZMN2-ME140

6)

DILM115

ZEV + ZEV-XSW-145

75

75

105

134

189

DM4-340-55K

NZMN2-ME140

6)

DILM150

ZEV + ZEV-XSW-145

90

100

146

161

227

DM4-340-75K

NZMN2-ME220

6)

DILM185

ZEV + ZEV-XSW-820

110

125

174

196

276

DM4-340-90K

NZMN2-ME220

6)

DILM225

ZEV + ZEV-XSW-820

132

200

174

231

326

NZMN3-ME350

6)

DILM250

ZEV + ZEV-XSW-820

160

250

202

279

393

DM4-340-110K NZMN3-ME350

6)

DILM300

ZEV + ZEV-XSW-820

200

300

300

349

492

DM4-340-160K NZMN3-ME350

6)

DILM400

ZEV + ZEV-XSW-820

250

400

370

437

616

DM4-340-200K NZMN3-ME450

6)

DILM500

ZEV + ZEV-XSW-820

315

500

500

544

767

DM4-340-250K NZMN3-ME550

6)

DILM580

ZEV + ZEV-XSW-820

400

600

600

683

963

DM4-340-315K NZMN3-ME875

6)

DILM750

ZEV + ZEV-XSW-820

500

750

750

860

1213

DM4-340-400K NZMN3-ME875

6)

DILM1000

ZEV + ZEV-XSW-820

560

900

960

1354

DM4-340-500K NZMN4-ME1400

6)

DILM1000

ZEV + ZEV-XSW-820

Notes

1)

At a different operating cycle, the r.m.s. current changes so that a higher-rated device may have to be used.

The switching and protective elements are always dimensioned for the following operating cycles (no bypass for any operating

cycle):

•

Devices DM4-340-7K5 to DM4-340-90K: each 10 switching operations per hour, continuous operation.

•

Devices DM4-340-110K and DM4-340-132K: each 10 switching operations per hour with at least 3 minutes no-load pause

before each start.

•

Devices from DM4-340-160K: each 3 switching operations per hour with at least 8 minutes no-load pause before each start.

For all other switching cycles or when a bypass is used, the effective rating changes and a different device is therefore

required.

•

The rated operational current (device) must be greater than the motor current (in-line operation) indicated on the motor’s

nameplate ("in-line" operation) or motor current/√3 (delta operation).

2)

Rated operational current relative to the specified load cycle

.

3)

Used to specify the current for which the supply cable must be dimensioned with the given operation and motor current. For

higher motor currents and for other operations (operating frequency, overcurrent, overcurrent time, duty factor), the current

value changes and must be modified accordingly.