48

MT-C series connectors are

designed for high voltage

applications up to 33 kV.

They are manufactured

from high purity Copper,

annealed and Tin plated.

The extended barrel en-

hances both electrical and

mechanical performance.

The stalk or pin makes

these connectors ideal for

terminating conductors

into contact blocks.

Details of the appropriate

crimping tools and dies are

shown on page 184.

HIGH VOLTAGE STALK CONNECTORS

MT-C

MT 25-C 8

6,8

8

35

80

MT 40 S-C 8

8,2

8

35

80

MT 40 S-C 10

8,2

10

35

80

MT 40 S-C 14-80

8,2

14

80

123

MT 35-C 8

8,2

8

35

80

MT 35-C 10

8,2

10

35

80

MT 35-C 14-80

8,2

14

80

123

MT 50 R-C 8

8,8

8

35

80

MT 50 R-C 10

8,8

10

35

80

MT 50 S-C 8

9,5

8

35

80

MT 50 S-C 10

9,5

10

35

80

MT 50 S-C 14-80

9,5

14

80

123

MT 50-C 8

9,5

8

35

80

MT 50-C 10

9,2

10

35

80

MT 50-C 14-80

9,5

14

80

123

MT 70 S-C 10

11,2

10

35

90

MT 70-C 10

11,2

10

35

90

MT 95 R-C 10

12,0

10

45

110

MT 95 R-C 12

12,0

12

45

110

MT 95 S-C 10

13,5

10

45

110

MT 95 S-C 12

13,5

12

45

110

MT 95 S-C 14-80

13,5

14

80

145

MT 95-C 10

13,5

10

45

110

MT 95-C 12

13,5

12

45

110

MT 95-C 14-80

13,5

14

80

145

MT 150 R-C 12

15,0

12

45

110

MT 150 R-C 16

15,0

16

45

110

MT 120-C 12

15,0

12

45

110

MT 120-C 16

15,0

16

45

110

MT 150 S-C 12

16,5

12

45

110

MT 150 S-C 14-80

16,5

14

80

145

MT 150 S-C 16

16,5

16

45

110

MT 150-C 10

16,5

10

45

110

MT 150-C 12

16,5

12

45

110

MT 150-C 14-80

16,5

14

80

145

MT 150-C 16

16,5

16

45

110

MT 200 R-C 10

17,0

10

45

110

MT 200 R-C 16

17,0

16

45

110

MT 185-C 10

18,0

10

45

110

MT 185-C 16

18,0

16

45

110

MT 240 R-C 12

19,5

12

50

115

MT 240 R-C 16

19,5

16

50

115

MT 315 R-C 16

21,5

16

50

115

MT 240-C 12

20,5

12

45

110

MT 240-C 16

20,5

16

50

115

MT 300-C 16

23,0

16

50

115

MT 315 S-C 16

24,0

16

60

130

Hydraulic

Tools

Conductor Size

(sqmm)

& Format

Quantity

Box/Bag

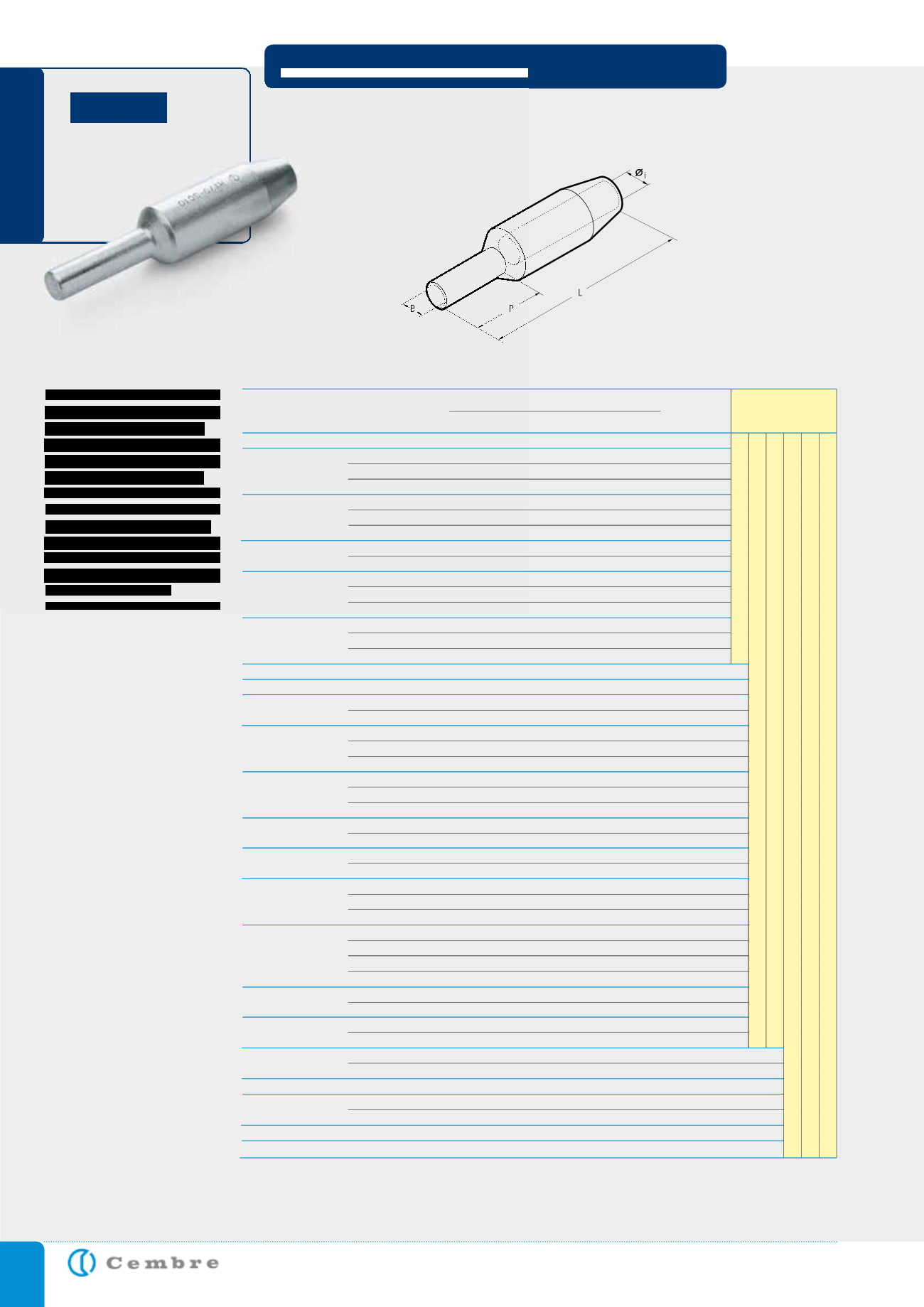

L

P

B

Øi

D i m e n s i o n s m m

Ref.

25 R

30 RC/S ÷ 40 S

35 BR/BS*

50 RC

50 S

50 BR/BS*

63 S ÷ 70 S

70 BR/BS*

80 S ÷ 95 RC

95 S ÷ 100 S

95 BR/BS*

120 RC/S ÷ 150 RC

120 BR/BS*

150 S ÷ 160 RC

150 BR/BS*

160 S ÷ 200 RC

185 BR/BS*

Conductor Format: R = Round, RC = Round Compact, S = Sector, BR = IEC228 (BS6360) Round, BS* = IEC228 (BS6360) Sector

* = Pre-rounding required, consult Cembre for appropriate die set

90/3

90/3

90/3

30/3

90/3

90/3

30/3

90/3

90/3

90/3

90/3

30/3

90/3

90/3

90/3

30/3

30/3

60/3

60/3

60/3

60/3

60/3

60/3

60/3

60/3

60/3

30/3

60/3

60/3

60/3

45/3

60/3

60/3

60/3

45/3

60/3

30/3

30/3

30/3

30/3

30/3

30/3

30/3

30/3

30/3

30/3

30/3

200 S ÷ 240 RC

240 BR/BS*

240 S ÷ 315 RC

315 S

300 BR/BS*

HT 81-U RHU 81

HT 120 and tools and heads with 130 kN crimping force

ECW-H3D

RHU 520

HT 51 RH 50 B 500E B 550E

B35-50MDE