45

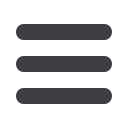

2A-2M.. series lugs are

manufactured from elec-

trolytic Copper tube con-

forming to EN13600.

The tube dimensions are

designed to optimise elec-

trical conductivity and me-

chanical strength.

Double length barrels en-

hance electrical and me-

chanical performance in

heavy duty applications.

Palms feature double stud

holes at standard 44.5mm

centres.

Other configurations are

available upon request.

Lugs are annealed to en-

sure ductility and satisfac-

tory performance when

subjected to deformation

and vibration.

The absence of an inspec-

tion hole prevents the in-

gress of water or moisture

into the crimped joint mak-

ing these terminals suitable

for outdoor applications.

Lugs are electrolytically Tin

plated to avoid oxidation.

Details of the appropriate

crimping tools and dies

are shown on pages 180

to 181.

E

HIGH VOLTAGE TERMINALS

two hole fixing

2A-2M

Cond.

Size

AWG

Ø

Stud

in.

Ref.

D i m e n s i o n s i n.

Quantity

Bag

Mechanical

Tools

Hydraulic

Tools

Ø

i

B M N E

L

d

50 8

2A10-2M12

10,0 21,0 14,0 12,0 44,5 112,5 13,2

25

TN 70 SE

TN 120 SE

B 35-45MDE

B 35-50MDE

HT 45-E

HT 51 B 550E

RH 50 B 500E

HT 81-U RHU 81

HT 120 and tools and heads with 130 kN crimping force

ECW-H3D

RHU 520

70

10

2A14-2M12

11,3 22,0 16,0 14,0 44,5 123,5 13,2

25

12

2A14-2M14

11,3 25,0 18,0 16,0 44,5 127,5 15,0

25

95

8

2A19-2M12

13,5 25,0 16,0 14,0 44,5 128,0 13,2

25

10

2A19-2M14

13,5 25,0 18,0 16,0 44,5 132,0 15,0

25

120

12

2A24-2M12

15,2 28,5 16,0 14,0 44,5 135,5 13,2

25

8

2A24-2M14

15,2 28,5 18,0 16,0 44,5 139,5 15,0

25

10

2A24-2M16

15,2 28,5 18,0 17,0 44,5 140,5 17,0

25

150

12

2A30-2M12

16,7 31,5 16,0 14,0 44,5 142,5 13,2

15

14

2A30-2M14

16,7 31,5 18,0 16,0 44,5 146,5 15,0

15

10

2A30-2M16

16,7 31,5 19,0 17,0 44,5 148,5 17,0

15

185

12

2A37-2M12

19,2 35,5 16,0 14,0 44,5 152,5 13,2

15

14

2A37-2M14

19,2 35,5 18,0 16,0 44,5 156,5 15,0

15

16

2A37-2M16

19,2 35,5 19,0 17,0 44,5 158,5 17,0

15

240

10

2A48-2M12

21,1 39,0 16,0 14,0 44,5 153,5 13,2

5

12

2A48-2M14

21,1 39,0 18,0 16,0 44,5 157,5 15,0

5

14

2A48-2M16

21,1 39,0 19,0 17,0 44,5 159,5 17,0

5

300

16

2A60-2M12

23,7 44,0 20,0 14,0 44,5 174,0 13,2

5

10

2A60-2M14

23,7 44,0 22,0 16,0 44,5 178,0 15,0

5

12

2A60-2M16

23,7 44,0 19,0 17,0 44,5 176,0 17,0

5

400

14

2A80-2M12

27,0 51,0 20,0 14,0 44,5 177,5 13,2

5

16

2A80-2M14

27,0 51,0 22,0 16,0 44,5 181,5 15,0

5

10

2A80-2M16

27,0 51,0 22,0 19,0 44,5 184,5 17,0

5

500

12

2A100-2M12

30,3 56,5 20,0 14,0 44,5 178,5 13,2

5

14

2A100-2M14

30,3 56,5 22,0 16,0 44,5 182,5 15,0

5

16

2A100-2M16

30,3 56,5 22,0 19,0 44,5 185,5 17,0

5

630

10

2A120-2M12

33,4 61,5 20,0 14,0 44,5 196,5 13,2

5

12

2A120-2M14

33,4 61,5 22,0 19,0 44,5 200,5 15,0

5

14

2A120-2M16

33,4 61,5 22,0 19,0 44,5 203,5 17,0

5

800

16

2A160-2M12

38,0 72,0 20,0 14,0 44,5 218,5 13,2

1

10

2A160-2M14

38,0 72,0 22,0 19,0 44,5 225,5 15,0

1

12

2A160-2M16

38,0 72,0 24,0 19,0 44,5 227,5 17,0

1

1000

14

2A200-2M12

44,0 80,0 20,0 14,0 44,5 233,5 13,2

1

16

2A200-2M14

44,0 80,0 22,0 16,0 44,5 237,5 15,0

1

16

2A200-2M16

44,0 80,0 22,0 19,0 44,5 240,5 17,0

1

12

2A200-2M20

44,0 80,0 24,0 23,0 44,5 246,5 21,0

1

File no. E125401

Not UL approved