41

SLEEVE CONNECTORS

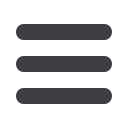

“C” connectors are manu-

factured from high purity

copper profiles and are

suitable for a variety of uses

either to create an earthing

network or tapping off from

overhead distribution lines.

Each connector is marked

as follows:

- Cembre trade mark

- Reference number

- Conductor size-Run

- Conductor size-Tap

- Number of crimps

- Die reference.

Details of the appropriate

crimping tools and dies are

shown on page 184.

C-C

Ref.

Conductor Size

sqmm

25-25

C 35-C 16 ST

35-35

C 35-C 35 ST

50-50

C 70-C 70 ST

63-63

C 95-C 70 ST

70-70

95-95

C 150-C 120 ST

120-120

125-125

C 150-C 150

120-120

C 185-C 95 ST

125-125

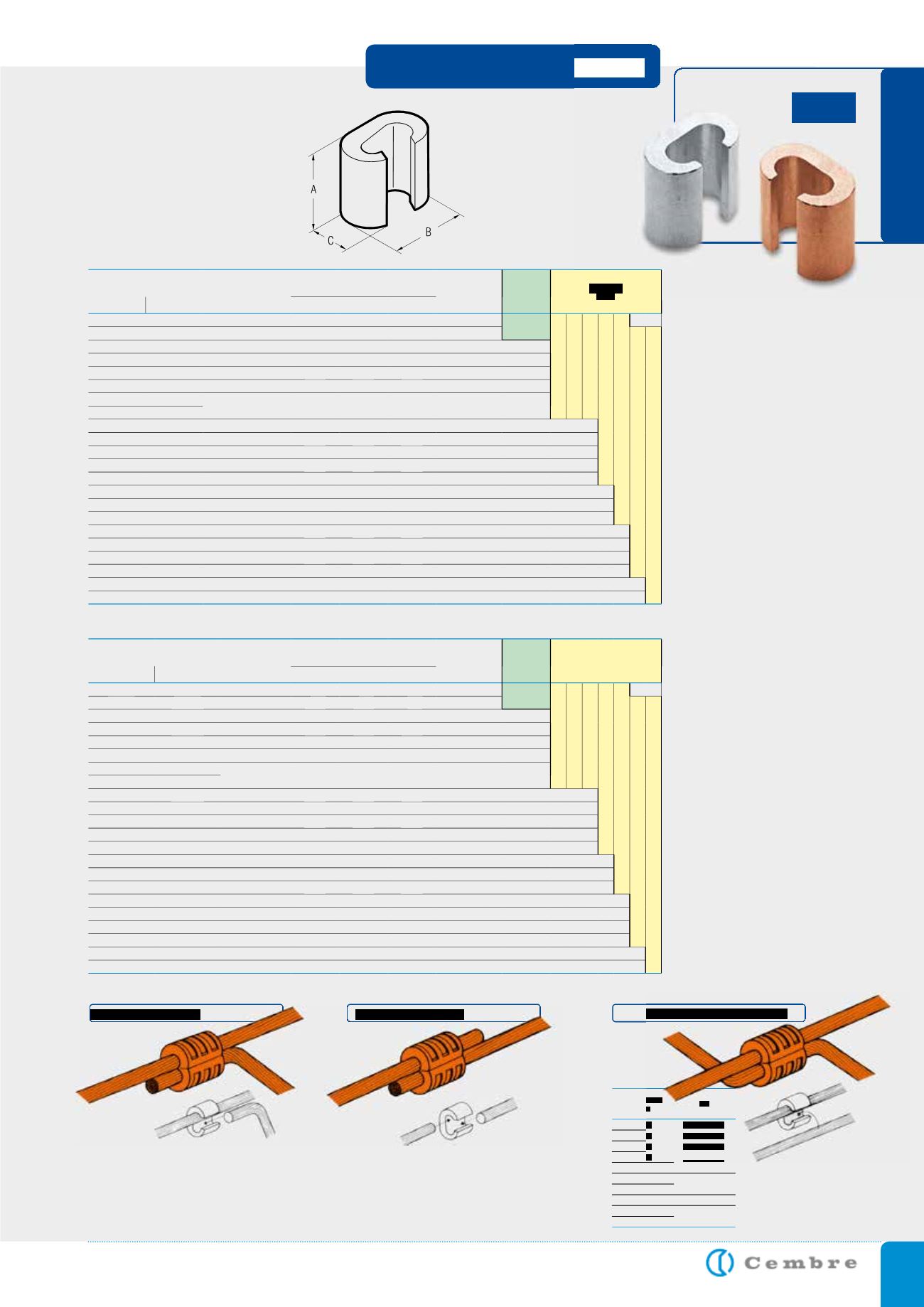

Example of tap connection

Example of joint connection

Example of joining two running conductors

Conductor Size

sqmm

Ref.

D i m e n s i o n s m m

Quantity

Box/Bag

Mechanical

Tools

Hydraulic

Tools

Run

Tap

A

B

C

6÷2,5 6÷1,5

C 6-C 6 ST

9,0

9,8

6,4

1.000/100

HP4-C10

B 35-45MDE

B 35-50MDE

HT 45-E

HT 51 RH 50 B 500E B 550E

HT 81-U RHU 81

10

10÷1,5

C 10-C 10 ST

12,0 12,6

8,4

500/100

HT 120 and tools and heads with 130 kN crimping force

ECW-H3D

16

16÷1,5

C 16-C 16 ST

17,0 19,4 12,0

500/100

25÷16 10÷1,5

C 25-C 10 ST

17,0 19,8 13,0

400/50

25

25÷16

C 25-C 25 ST

17,0 21,4 13,0

300/50

40÷35 16÷1,5

C 35-C 16 ST

21,0 24,6 15,4

200/25

40÷35 40÷25

C 35-C35 ST

21,0 26,6 15,6

200/25

50

25÷10

70÷63 25÷1,5

C 70-C 25 N ST

21,0 26,4 17,5

200/25

50

25÷4

C 50-C 25 ST

25,0 32,9 21,0

100/25

50

50÷35

C 50-C 50 ST

26,0 33,0 21,0

100/25

70÷50 40÷4

C 70-C 35 ST

28,0 33,0 21,0

100/25

70÷50 70÷35

C 70-C 70 ST

28,0 34,0 21,0

100/25

100÷95 40÷4

C 95-C 35 ST

29,0 40,6 26,0

50/25

100÷95 70÷40

C 95-C 70 ST

29,0 41,0 26,0

50/25

100÷95 100÷63

C 95-C 95 ST

29,0 41,0 26,0

50/25

125÷110 125÷25

C 120-C 120 ST

30,0 45,0 28,0

50/25

160÷150 125÷25

C 150-C 120 ST

31,0 45,0 28,0

50/25

150 150÷63

C 150-C 150 ST

30,0 45,0 28,0

50/25

185 100÷16

C 185-C 95 ST

31,0 45,0 28,0

50/25

185÷120 185÷120

C 185-C 185 ST

22,6 68,0 34,0

30/15

240÷150 120÷95

C 240-C 120 ST

22,6 68,0 34,0

30/15

Conductor Size

sqmm

Ref.

D i m e n s i o n s m m

Quantity

Box/Bag

Mechanical

Tools

Hydraulic

Tools

Run

Tap

A

B

C

6÷2,5

6÷1,5

C 6-C 6

9,0

9,8

6,4

1.000/100

HP4-C10

B 35-45MDE

B 35-50MDE

HT 45-E

HT 51 RH 50 B 500E B 550E

HT 81-U RHU 81

10

10÷1,5

C 10-C 10

12,0 12,6

8,4

500/100

HT 120 and tools and heads with 130 kN crimping force

ECW-H3D

16

16÷1,5

C 16-C 16

17,0 19,4 12,0

500/100

25÷16

10÷1,5

C 25-C 10

17,0 19,8 13,0

400/50

25

25÷16

C 25-C 25

17,0 21,4 13,0

300/50

40÷35

16÷1,5

C 35-C 16

21,0 24,6 15,4

200/25

40÷35

40÷25

C 35-C35

21,0 26,6 15,6

200/25

50

25÷10

70÷63

25÷1,5

C 70-C 25 N

21,0 26,4 17,5

200/25

50

25÷4

C 50-C 25

25,0 32,9 21,0

100/25

50

50÷35

C 50-C 50

26,0 33,0 21,0

100/25

70÷50

40÷4

C 70-C 35

28,0 33,0 21,0

100/25

70÷50

70÷35

C 70-C 70

28,0 34,0 21,0

100/25

100÷95

40÷4

C 95-C 35

29,0 40,6 26,0

50/25

100÷95 70÷40

C 95-C 70

29,0 41,0 26,0

50/25

100÷95 100÷63

C 95-C 95

29,0 41,0 26,0

50/25

125÷110 125÷25

C 120-C 120

30,0 45,0 28,0

50/25

160÷150 125÷25

C 150-C 120

31,0 45,0 28,0

50/25

150

150÷63

C 150-C 150

30,0 45,0 28,0

50/25

185

100÷16

C 185-C 95

31,0 45,0 28,0

50/25

185÷120 185÷120

C 185-C 185

22,6 68,0 34,0

30/15

240÷150 120÷95

C 240-C 120

22,6 68,0 34,0

30/15

bright surface version

tin plated version