36

C series lugs are manufac-

tured from electrolytic Cop-

per tube.

The dimensions of the tube

are designed to obtain the

most efficient electrical

conductivity and mechani-

cal strength to resist vibra-

tion and pull out.

Cembre lugs are annealed

to guarantee optimum duc-

tility, an absolute necessity

for connectors which will

have to withstand the se-

vere deformation arising

when compressed and any

bending of the palm during

installation.

In applications subject to vi-

bration, terminals have to

perform a reliable connec-

tion, the annealing process

plays a vital role in avoiding

cracking or breaks between

the barrel and palm.

The presence of an inspec-

tion hole facilitates full in-

sertion of the conductor.

The barrel length has been

designed to allow easy and

accurate positioning of the

dies during the crimping

operation.

Lugs are electrolytically tin-

plated to avoid oxidation.

The tongue is clearly

marked with wire size and

die index for Cembre tools.

UL listed for US and Canada

per UL486A up to 35 KV.

C series lugs are an impor-

tant part of Cembre crimp-

ing systems for power car-

rying conductors.

Details of the appropriate

crimping tools and dies are

shown on page 188.

Cembre technicians are

available to provide techni-

cal advice as required.

Please consult Cembre for

products not listed.

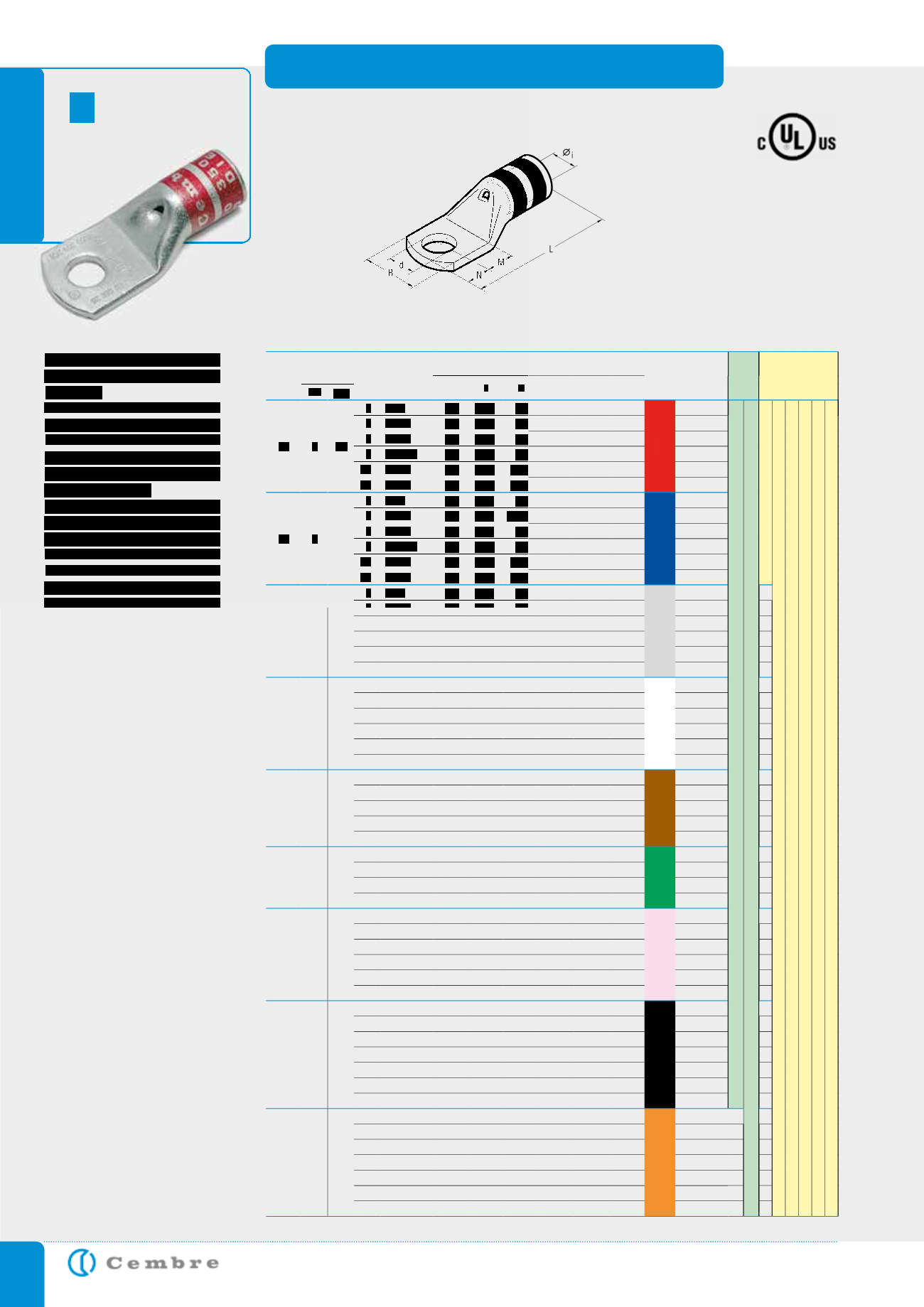

C

File no. E125401

Cond.

Size

sqmm

Conductor

AWG

Ø

Stud

mm

Ref.

D i m e n s i o n s m m

Colour

Code

Quantity

Box/Bag

Mechanical

Tools

Hydraulic

Tools

Ø

i

B

M

N L

d

Size Navy

10

8 23

4

C8-8

4,6 10,0

5,0 4,0 22,5 4,3

RED

600/50

TN 70 SE

TN 120 SE

B15MDE

B35-50MDE

HT 51 RH 50 B 500E

HT 120 and tools and heads with 130 kN crimping force

ECW-H3D

RHU 520

5

C8-10

4,6 10,0

6,5 6,0 26,0 5,3

600/50

6

C8-14

4,6 11,0

7,0 6,0 26,5 6,4

600/50

8

C8-516

4,6 15,0

9,0 8,0 30,5 8,4

600/50

10

C8-38

4,6 18,0

11,0 10,0 34,5 10,5

600/50

12

C8-12

4,6 19,0

14,0 12,0 39,5 13,2

600/50

16

6

4

C6-8

5,8 11,5

5,0 4,0 25,5 4,3

BLUE

600/50

5

C6-10

5,8 11,5

6,5,0 6,0 29,0 5,3

600/50

6

C6-14

5,8 11,5

7,0 6,0 29,5 6,4

600/50

8

C6-516

5,8 15,0

9,0 8,0 33,5 8,4

600/50

10

C6-38

5,8 18,0

11,0 10,0 37,5 10,5

600/50

12

C6-12

5,8 20,0

14,0 12,0 42,5 13,2

400/50

25

4 40

4

C4-8

6,2 12,5

5,0 4,0 25,5 4,3

GREY

600/50

5

C4-10

6,2 12,5 6,5 6,0 29,0 5,3

600/50

6

C4-14

6,2 12,5 7,0 6,0 29,5 6,4

600/50

8

C4-516

6,2 15,0 9,0 8,0 33,5 8,4

600/50

10

C4-38

6,2 18,0 11,0 10,0 37,5 10,5

400/50

12

C4-12

6,2 20,0 14,0 12,0 42,5 13,2

400/50

3 50

4

C3-8

7,0 14,0 5,0 4,0 28,0 4,3

WHITE

600/50

5

C3-10

7,0 14,0 6,5 6,0 31,5 5,3

600/50

6

C3-14

7,0 14,0 7,0 6,0 32,0 6,4

600/50

8

C3-516

7,0 15,0 9,0 8,0 36,0 8,4

600/50

10

C3-38

7,0 18,0 11,0 10,0 40,0 10,5

400/50

12

C3-12

7,0 21,0 14,0 12,0 45,0 13,2

400/50

35

2 60

5

C2-10

7,6 17,0 6,5 6,0 33,0 5,3

BROWN

400/50

6

C2-14

7,6 17,0 7,0 6,0 33,5 6,4

400/50

8

C2-516

7,6 17,0 9,0 8,0 37,5 8,4

400/50

10

C2-38

7,6 19,0 11,0 10,0 41,5 10,5

400/50

12

C2-12

7,6 21,0 14,0 12,0 46,5 13,2

200/50

1 75

6

C1-14

8,9 17,0 7,0 6,0 34,5 6,4

GREEN

400/50

8

C1-516

8,9 17,0 9,0 8,0 38,5 8,4

400/50

10

C1-38

8,9 19,0 11,0 10,0 42,5 10,5

400/50

12

C1-12

8,9 21,0 14,0 12,0 47,5 13,2

200/50

50

1/0 100

6

C1/0-14

10,0 19,0 8,0 7,0 40,5 6,4

PINK

200/25

8

C1/0-516

10,0 19,0 9,0 8,0 42,5 8,4

200/25

10

C1/0-38

10,0 20,0 11,0 10,0 46,5 10,5

200/25

12

C1/0-12

10,0 21,0 14,0 12,0 51,5 13,2

200/25

14

C1/0-916

10,0 25,0 16,0 14,0 55,5 15,0

200/25

16

C1/0-58

10,0 26,0 18,0 16,0 59,5 17,0

200/25

70

2/0 125

6

C2/0-14

11,3 21,0 8,0 7,0 44,0 6,4

BLACK

200/25

8

C2/0-516

11,3 21,0 9,0 8,0 46,0 8,4

200/25

10

C2/0-38

11,3 21,0 11,0 10,0 50,0 10,5

200/25

12

C2/0-12

11,3 22,0 14,0 12,0 55,0 13,2

200/25

14

C2/0-916

11,3 25,0 16,0 14,0 59,0 15,0

100/25

16

C2/0-58

11,3 26,0 18,0 16,0 63,0 17,0

100/25

20

C2/0-34

11,3 29,5 22,0 20,0 75,0 21,0

100/25

95

3/0 150

6

C3/0-14

12,4 23,0 8,0 7,0 45,0 6,4

ORANGE

200/25

8

C3/0-516

12,4 23,0 9,0 8,0 47,0 8,4

200/25

10

C3/0-38

12,4 23,0 11,0 10,0 51,0 10,5

100/25

12

C3/0-12

12,4 24,0 14,0 12,0 56,0 13,2

100/25

14

C3/0-916

12,4 27,0 16,0 14,0 60,0 15,0

100/25

16

C3/0-58

12,4 28,0 18,0 16,0 64,0 17,0

100/25

20

C3/0-34

12,4 31,5 22,0 20,0 72,0 21,0

100/25

COLOUR CODED COPPER CRIMPING LUGS

for Copper conductors