34

DR series lugs are manu-

factured from electrolytic

Copper tube and designed

to obtain high electrical

conductivity combined with

the mechanical strength

required to resist vibration

and pull out.

Cembre lugs are annealed

and Tin plated for improved

surface protection.

The annealing process

optimises the structural

features of the material al-

lowing easier crimping and

greater resistance to me-

chanical stresses.

Dimensions are according

to DIN 46235.

The barrel entrance of the

lug is chamfered to allow

easy conductor insertion,

while its length facilitates

precise positioning in the

crimping die.

Each lug is marked with:

- Cembre logo and part

code.

- conductor type and csa

(mm

2

).

- Stud Ø (mm).

- crimping die code

Details of the appropriate

crimping tools and dies are

shown on page 189.

Consult us for special

requirements

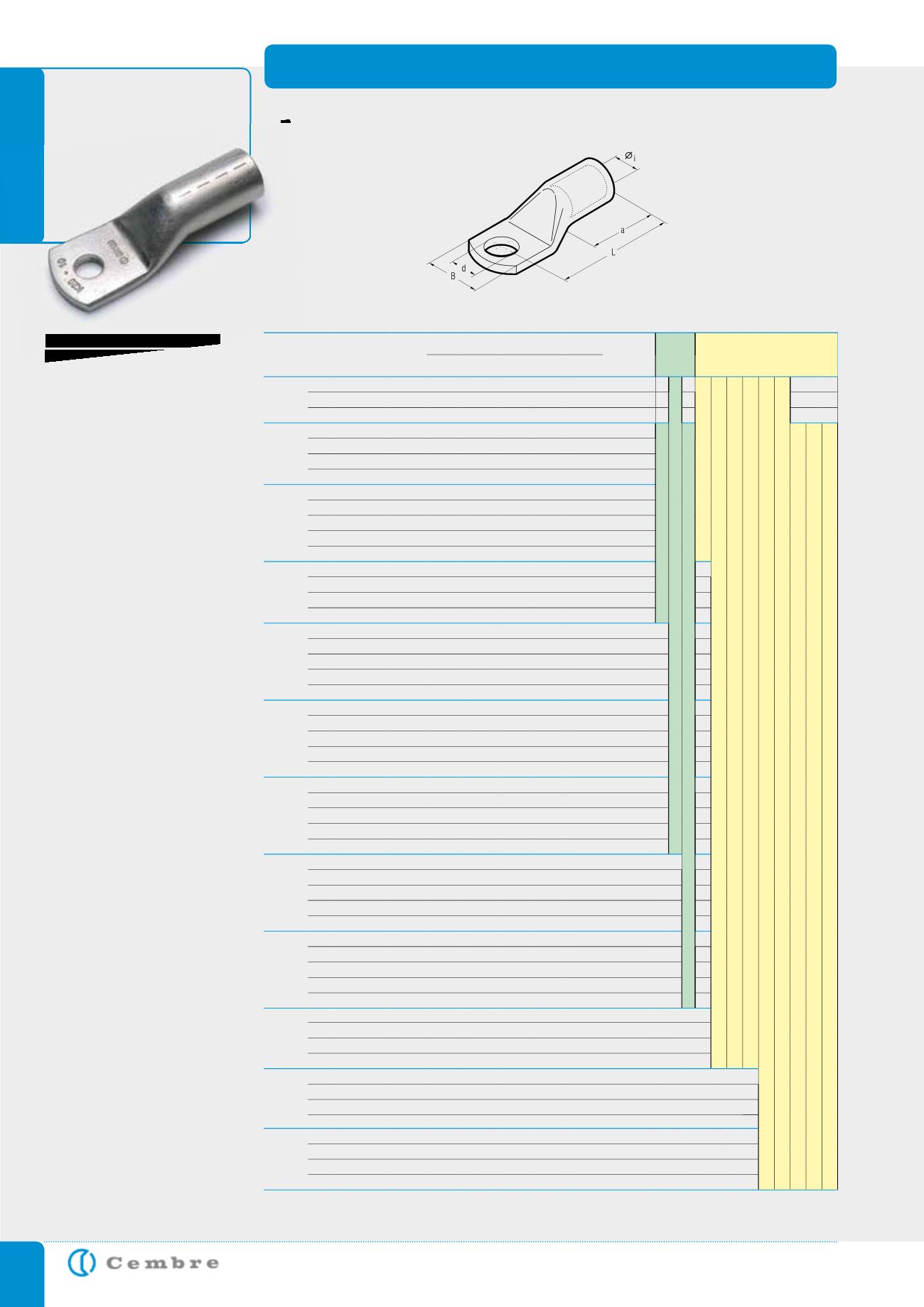

COPPER TUBE CRIMPING LUGS ACCORDING TO DIN 46235

for Copper conductors

DR

Conductor

Size

sqmm

Ø

Stud

mm

Ref.

Code

D i m e n s i o n s m m

Quantity

Box/Bag

Mechanical

Tools

Hydraulic

Tools

Ø

i

d

L

B

a

6

5

DR6-5

5 3,8 5,3 24,0 8,5 10,0

800/100

TND 6-70

B 15MDE

B 35-45MDE

B 35-50M0E

HT 45-E

HT 51 RH 50 B 500E

HT 81-U RHU 81

6

DR6-6

5 3,8 6,4 24,0 9,0 10,0

800/100

8

DR6-8*

5 3,8 8,4 26,0 13,0 10,0

800/100

10

5

DR10-5

6 4,5 5,3 27,5 10,0 10,0

800/100

HN-D25

TND 10-120

HT 120 and tools and heads with 130 kN crimping force

ECW-H3D

RHU 520

6

DR10-6

6 4,5 6,4 27,0 10,0 10,0

800/100

8

DR10-8*

6 4,5 8,4 28,0 13,0 10,0

800/100

10

DR10-10*

6 4,5 10,5 28,5 15,0 10,0

800/100

16

5

DR16-5*

8 5,5 5,3 36,0 13,0 20,0

400/100

6

DR16-6

8 5,5 6,4 36,0 13,0 20,0

400/100

8

DR16-8

8 5,5 8,4 37,0 13,0 20,0

400/100

10

DR16-10

8 5,5 10,5 40,0 17,0 20,0

400/100

12

DR16-12*

8 5,5 13,0 41,0 19,0 20,0

400/100

25

6

DR25-6

10 7,0 6,4 39,0 14,6 20,0

400/100

8

DR25-8

10 7,0 8,4 39,5 16,0 20,0

400/100

10

DR25-10

10 7,0 10,5 40,0 17,0 20,0

200/100

12

DR25-12

10 7,0 13,0 40,5 19,0 20,0

200/100

35

6

DR35-6*

12 8,2 6,4 42,5 17,5 20,0

200/100

8

DR35-8

12 8,2 8,4 42,0 17,0 20,0

200/100

10

DR35-10

12 8,2 10,5 43,0 19,0 20,0

200/100

12

DR35-12

12 8,2 13,0 43,0 21,0 20,0

200/100

16

DR35-16*

12 8,2 17,0 44,0 28,0 20,0

200/100

50

6

DR50-6*

14 10,0 6,4 52,0 20,0 28,0

100/25

8

DR50-8

14 10,0 8,4 52,0 20,0 28,0

100/25

10

DR50-10

14 10,0 10,5 53,0 22,0 28,0

100/25

12

DR50-12

14 10,0 13,0 53,0 24,0 28,0

100/25

16

DR50-16

14 10,0 17,0 57,0 28,0 28,0

100/25

70

8

DR70-8

16 11,5 8,4 56,0 24,0 28,0

50/25

10

DR70-10

16 11,5 10,5 56,0 24,0 28,0

50/25

12

DR70-12

16 11,5 13,0 56,0 24,0 28,0

50/25

16

DR70-16

16 11,5 17,0 60,0 30,0 28,0

50/25

20

DR70-20*

16 11,5 21,0 84,5 30,0 28,0

50/25

95

8

DR95-8*

18 13,5 8,4 65,0 28,0 35,0

50/25

10

DR95-10

18 13,5 10,5 66,0 28,0 35,0

50/25

12

DR95-12

18 13,5 13,0 66,0 28,0 35,0

50/25

16

DR95-16

18 13,5 17,0 65,5 32,0 35,0

50/25

20

DR95-20*

18 13,5 21,0 71,0 33,0 35,0

50/25

120

8

DR120-8*

20 15,5 8,4 70,0 31,0 35,0

50/25

10

DR120-10

20 15,5 10,5 70,0 32,0 35,0

50/25

12

DR120-12

20 15,5 13,0 70,5 32,0 35,0

50/25

16

DR120-16

20 15,5 17,0 70,0 32,0 35,0

50/25

20

DR120-20

20 15,5 21,0 72,0 36,0 35,0

50/25

150

10

DR150-10

22 17,0 10,5 79,0 34,0 35,0

50/25

12

DR150-12

22 17,0 13,0 78,5 34,0 35,0

50/25

16

DR150-16

22 17,0 17,0 78,0 34,0 35,0

50/25

20

DR150-20

22 17,0 21,0 78,0 40,0 35,0

50/25

185

10

DR185-10

25 19,0 10,5 83,0 37,0 40,0

25/25

12

DR185-12

25 19,0 13,0 82,5 37,0 40,0

25/25

16

DR185-16

25 19,0 17,0 82,0 37,0 40,0

25/25

20

DR185-20

25 19,0 21,0 83,0 40,0 40,0

25/25

240

10

DR240-10*

28 21,5 10,5 92,0 42,0 40,0

20/10

12

DR240-12

28 21,5 13,0 92,0 42,5 40,0

20/10

16

DR240-16

28 21,5 17,0 92,0 42,5 40,0

20/10

20

DR240-20

28 21,5 21,0 92,0 45,0 40,0

20/10

* Dimensions of the tube according to DIN 46235; Stud hole not included within the standard.