32

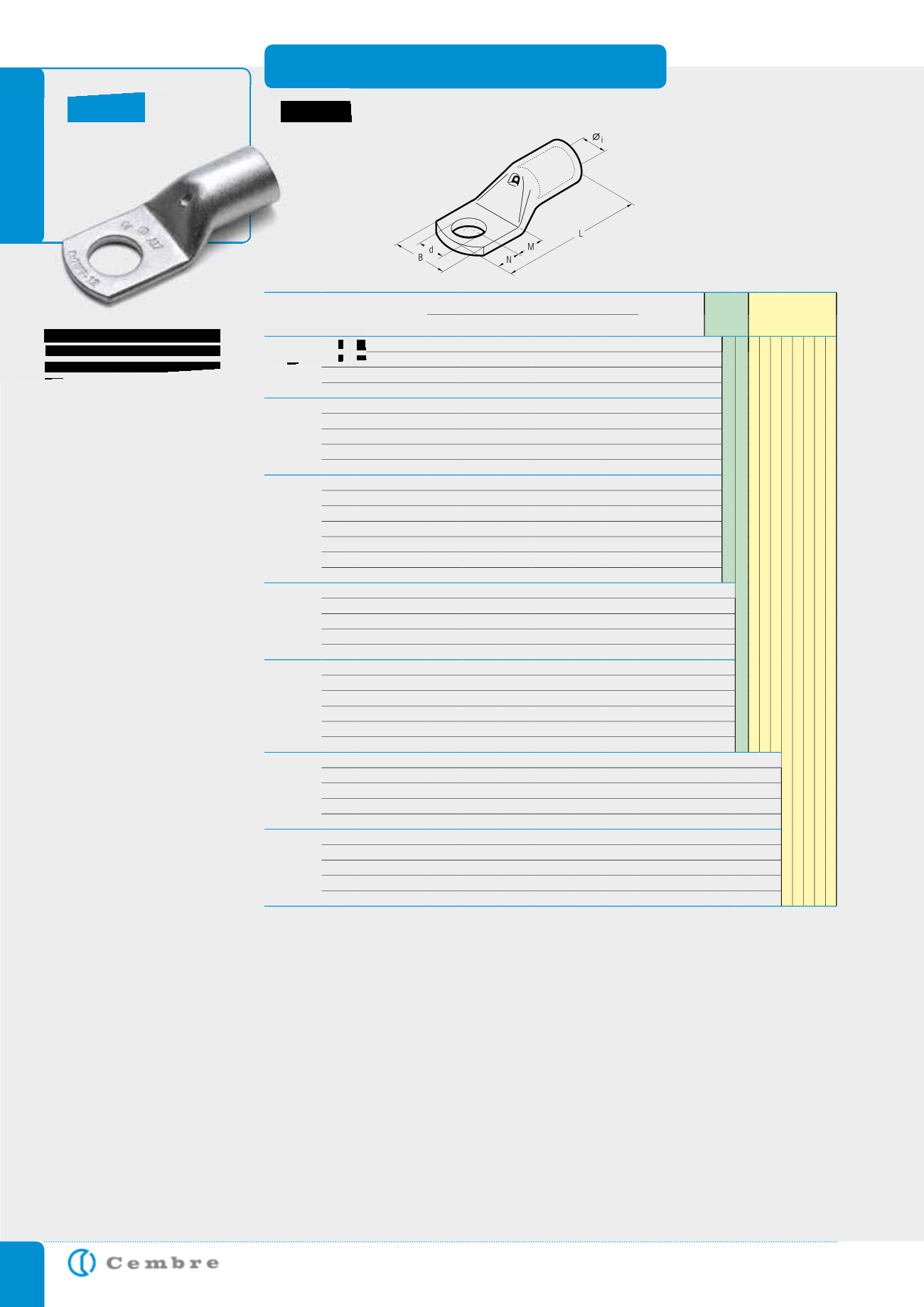

COPPER TUBE CRIMPING LUGS

for extra flexible Copper conductors

These lugs are particularly

recommended for use with

extra flexible conductors on

for instance, welding ma-

chines.

A-M series lugs are de-

signed to suit panel appli-

cations.

The dimensions of the tube

are designed to obtain the

most efficient electrical

conductivity and mechani-

cal strength to resist vibra-

tion and pull out.

Cembre lugs are annealed

to guarantee optimum duc-

tility and electrolytically Tin

plated to avoid oxidation.

The presence of an inspec-

tion hole facilitates full in-

sertion of the conductor.

Details of the appropriate

crimping tools and dies

are shown on pages 178

to 179.

A-M

Conductor Size

Extra Flexible

sqmm

Ø

Stud

mm

Ref.

D i m e n s i o n s m m

Quantity

Box/Bag

Mechanical

Tools

Hydraulic

Tools

Ø

i

B

M N L

d

35

6

A 9-M 6/15

9,3 15,0 8,0 7,0 38,5 6,4

400/100

TN 70 SE

TN 120 SE

B 35-45MDE

B 35-50MDE

HT 45-E

HT 51 RH 50 B 500E B 550E

HT 81-U RHU 81

HT 120 and tools and heads with 130 kN crimping force

ECW-H3D

RHU 520

8

A 9-M 8

9,3 17,0 9,0 8,0 40,5 8,4

400/100

10

A 9-M 10

9,3 18,5 11,0 10,0 44,5 10,5

400/100

12

A 9-M 12

9,3 21,0 14,0 12,0 49,5 13,2

300/50

50

6

A 12-M 6/15

11,0 15,0 8,0 7,0 40,5 6,4

200/50

8

A 12-M 8

11,0 19,3 9,0 8,0 42,5 8,4

200/50

10

A 12-M 10

11,0 19,3 11,0 10,0 46,5 10,5

200/50

10

A 12-M 10/19

11,0 19,0 11,0 10,0 46,5 10,5

200/50

12

A 12-M 12

11,0 22,0 14,0 12,0 51,5 13,2

200/50

70

6

A 17-M 6

13,0 23,0 8,0 7,0 45,0 6,4

200/50

8

A 17-M 8

13,0 23,0 9,0 8,0 47,0 8,4

150/50

10

A 17-M 10

13,0 23,0 11,0 10,0 51,0 10,5

150/50

10

A 17-M 10/19

13,0 19,0 11,0 10,0 51,0 10,5

200/50

12

A 17-M 12

13,0 23,0 14,0 12,0 56,0 13,2

150/50

14

A 17-M 14

13,0 25,0 15,5 12,0 57,5 15,0

150/25

16

A 17-M 16

13,0 27,0 16,5 13,5 60,0 17,0

150/25

95

8

A 20-M 8

15,0 27,0 9,0 8,0 50,0 8,4

100/25

10

A 20-M 10

15,0 27,0 11,0 10,0 54,0 10,5

100/25

12

A 20-M 12

15,0 27,0 14,0 12,0 59,0 13,2

100/25

14

A 20-M 14

15,0 27,0 15,5 12,0 60,5 15,0

100/25

16

A 20-M 16

15,0 27,0 16,5 13,5 63,0 17,0

100/25

120

8

A 29-M 8

16,5 30,0 9,0 8,0 53,5 8,4

100/25

10

A 29-M 10

16,5 30,0 11,0 10,0 57,5 10,5

100/25

12

A 29-M 12

16,5 30,0 14,0 12,0 62,5 13,2

100/25

14

A 29-M 14

16,5 30,0 15,5 12,0 64,0 15,0

100/25

16

A 29-M 16

16,5 30,0 16,5 13,5 66,5 17,0

100/25

20

A 29-M 20

16,5 30,0 22,0 20,0 78,5 21,0

75/25

150

10

A 35-M 10

19,2 34,2 13,0 11,0 65,5 10,5

50/25

12

A 35-M 12

19,2 34,2 16,0 14,0 71,5 13,2

50/25

14

A 35-M 14

19,2 34,2 18,0 16,0 75,5 15,0

50/25

16

A 35-M 16

19,2 34,2 19,0 17,0 77,5 17,0

50/25

20

A 35-M 20

19,2 34,2 22,0 20,0 83,5 21,0

50/25

185

10

A 40-M 10

21,0 37,5 13,0 11,0 73,0 10,5

30/15

12

A 40-M 12

21,0 37,5 16,0 14,0 79,0 13,2

30/15

14

A 40-M 14

21,0 37,5 18,0 16,0 83,0 15,0

30/15

16

A 40-M 16

21,0 37,5 19,0 17,0 85,0 17,0

30/15

20

A 40-M 20

21,0 37,5 22,0 20,0 91,0 21,0

30/15

fl

e

x

i

b

l

e

c

o

n

d

u

c

t

o

r

s

•

f

o

r

f

i

n

e

s

t

r

a

n

d

e

d

•

SPECIAL