46

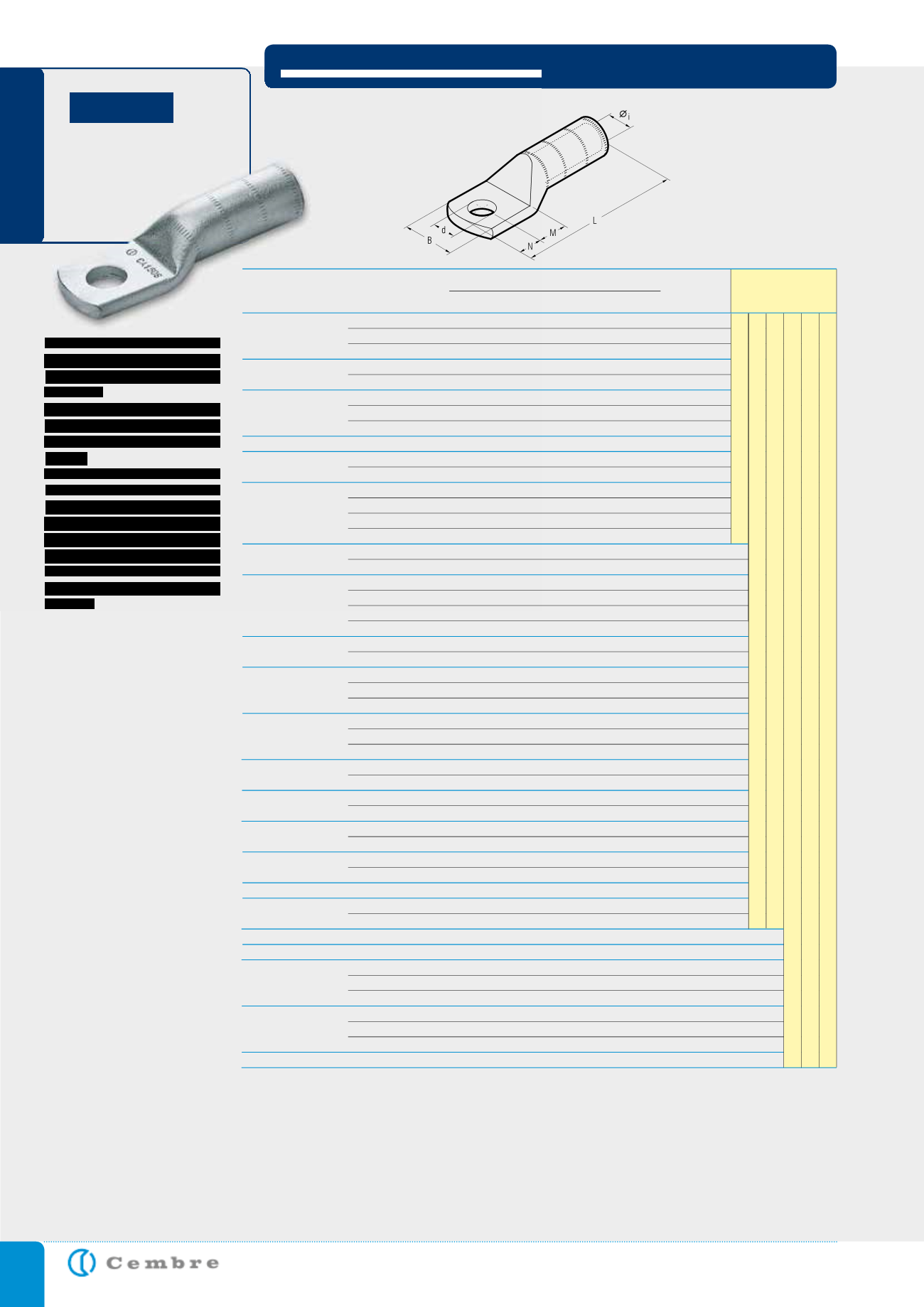

Series CA-M and 2A-M

terminals are designed for

high voltage applications up

to 33 kV.

They are manufactured

from high purity Copper

tube, annealed and Tin

plated.

The extended barrel en-

hances both electrical and

mechanical performance.

The absence of an inspec-

tion hole prevents moisture

entry into the crimped joint

and makes these terminals

suitable for outdoor appli-

cations.

Details of the appropriate

crimping tools and dies are

shown on page 184.

HIGH VOLTAGE HEAVY DUTY COPPER TERMINALS

CA-M

Hydraulic

Tools

8

CA 25-M 8

6,8 14,0

9

8

65,0

8,4

10

CA 25-M 10

6,8 18,0 13

11

72,0 10,5

12

CA 25-M 12

6,8 21,0 16

14

78,0 13,2

12

CA 40 S-M 12

8,2 21,0 16

14

79,0 13,2

16

CA 40 S-M 16

8,2 26,0 19

17

85,0 17,0

10

CA 35-M 10

8,25 21,0 13

11

73,0 10,5

12

CA 35-M 12

8,25 21,0 16

14

79,0 13,2

16

CA 35-M 16

8,25 26,0 19

17

85,0 17,0

12

CA 50 R-M 12

8,7 20,5 16

14

79,0 13,2

12

CA 50 S-M 12

9,5 21,0 16

14

79,0 13,2

16

CA 50 S-M 16

9,5 26,0 19

17

85,0 17,0

10

CA 50-M 10

9,5 21,0 13

11

73,0 10,5

12

CA 50-M 12

9,5 21,0 16

14

79,0 13,2

14

CA 50-M 14

9,5 25,0 18

16

83,0 15,0

16

CA 50-M 16

9,5 26,0 19

17

85,0 17,0

12

CA 70 S-M 12

11,0 28,0 16

14

81,2 13,2

16

CA 70 S-M 16

11,0 30,0 19

17

87,2 17,0

10

CA 70 S-M 10

11,0 26,0 13

11

75,2 10,5

12

CA 70 S-M 12

11,0 28,0 16

14

81,2 13,2

14

CA 70 S-M 14

11,0 28,0 18

16

85,2 15,0

16

CA 70 S-M 16

11,0 30,0 19

17

87,2 17,0

12

CA 95 R-M 12

12,0 28,0 16

14

91,0 13,2

14

CA 95 R-M 14

12,0 29,0 18

16

95,0 15,0

12

CA 95 S-M 12

13,5 28,0 16

14

91,0 13,2

14

CA 95 S-M 14

13,5 29,0 18

16

94,5 15,0

16

CA 95 S-M 16

13,5 30,0 20

17

97,0 17,0

10

CA 95-M 10

13,5 28,0 13

11

85,0 10,5

12

CA 95-M 12

13,5 28,0 16

14

91,0 13,2

16

CA 95-M 16

13,5 30,0 20

17

97,0 17,0

12

CA 150 R-M 12

15,0 31,0 16

14

97,0 13,2

14

CA 150 R-M 14

15,0 31,0 18

16 101,0 15,0

12

CA 120-M 12

15,0 31,0 16

14

97,0 13,2

16

CA 120-M 16

15,0 31,0 19

17 103,0 17,0

12

CA 150 S-M 12

16,5 32,0 16

14

97,0 13,2

14

CA 150 S-M 14

16,5 32,0 18

16 101,0 15,0

12

CA 150-M 12

16,5 32,0 16

14

97,0 13,2

16

CA 150-M 16

16,5 32,0 19

17 103,0 17,0

14

CA 200 R-M 14

17,0 32,5 18

16 101,0 15,0

12

CA 185-M 12

18,0 33,5 16

14

97,0 13,2

16

CA 185-M 16

18,0 33,5 19

17 103,0 17,0

14

CA 240 R-M 14

19,2 43,0 18

16 107,0 15,0

14

CA 315 R-M 14

21,5 43,0 18

16 105,0 15,0

12

CA 240-M 12

20,5 42,0 16

14 103,0 13,2

16

CA 240-M 16

20,5 42,0 19

17 109,0 17,0

20

CA 240-M 20

20,5 42,0 22

20 115,0 21,0

12

CA 300-M 12

23,0 43,5 16

14 109,5 13,2

16

CA 300-M 16

23,0 43,5 19

17 115,5 17,0

20

CA 300-M 20

23,0 43,5 22

20 121,5 21,0

14

CA 315 S-M 14

23,7 44,0 18

16 105,0 15,0

300/50

200/50

200/50

150/50

100/50

150/50

150/50

150/50

150/50

150/50

100/50

150/50

150/50

100/50

100/50

50/25

50/25

50/25

50/25

50/25

50/25

50/25

50/25

50/25

50/25

50/25

50/25

50/25

50/25

30/15

30/15

30/15

30/15

30/15

30/15

30/15

30/15

30/15

30/15

30/15

15/5

15/5

15/5

15/5

15/5

15/5

15/5

15/5

15/5

Conductor Size

(sqmm)

& Format

Ø

Stud

mm

Quantity

Box/Bag

Ø

i

B

M N L

d

D i m e n s i o n s m m

Ref.

25 R/BR/BS*

35 BR/BS*

30 RC/S ÷ 40 S

50 RC

50 S

50 BR/BS*

63 S ÷ 70 S

70 BR/BS*

80 S ÷ 95 RC

95 S ÷ 100 S

95 BR/BS*

120 RC/S ÷ 150 RC

120 BR/BS*

150 S ÷ 160 RC

150 BR/BS*

185 BR/BS*

240 BR/BS*

300 BR/BS*

160 S ÷ 200 RC

200 S ÷ 240 RC

240 S ÷ 315 RC

315 S

Conductor Format: R = Round, RC = Round Compact, S = Sector, BR = IEC228 (BS6360) Round, BS* = IEC228 (BS6360) Sector

* = Pre-rounding required, consult Cembre for appropriate die set

HT 81-U RHU 81

HT 120 and tools and heads with 130 kN crimping force

ECW-H3D

RHU 520

HT 51 RH 50 B 500E B 550E

B35-50MDE