47

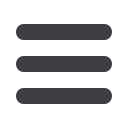

CA-2M and 2A-2M Copper

Tube Terminal Lugs are de-

signed for high voltage ap-

plications up to 33kV.

Manufactured from high

purity Copper tube, an-

nealed and Tin plated.

The extended barrel en-

hances electrical and me-

chanical performance.

The absence of an inspec-

tion hole prevents moisture

entry into the crimped joint.

Featuring an extended

palm with two fixing holes

at 44.5mm centres.

Details of the appropriate

crimping tools and dies are

shown on page 184.

Conductor Format: R = Round

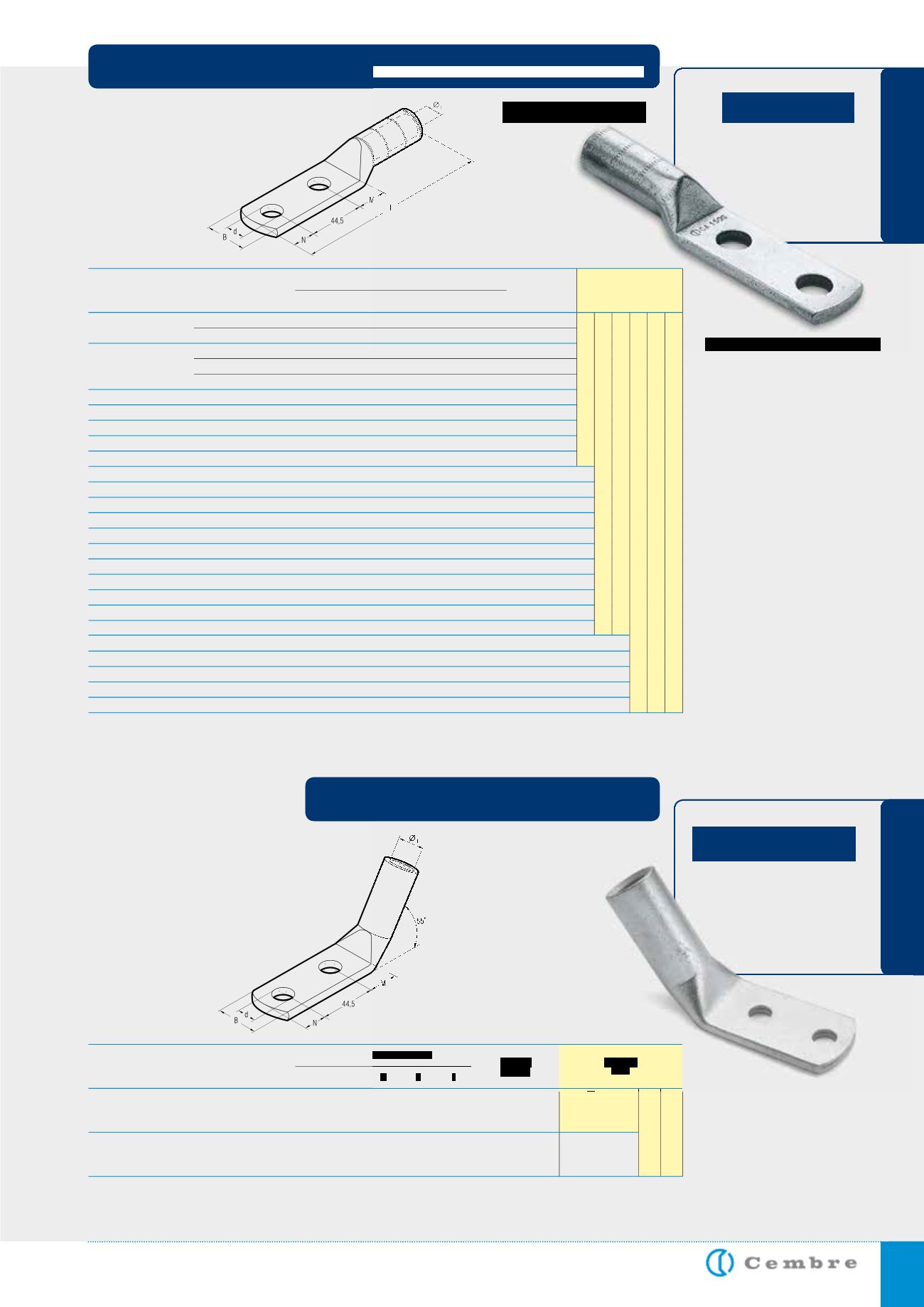

The 2A-2M/55° Copper

Tube Terminal Lugs have the

same characteristics as the

CA-2M and 2A-2M ranges,

with the additional feature of

the palm bent at 55°.

Hydraulic

Tools

14

2 A 80 - 2 M 14/55°

27,0 51,0 22

16

15

14

2 A 120 - 2 M 14/55°

33,4 61,5 22

16

15

10/5

15/3

Conductor Size

(sqmm)

& Format

Ø

Stud

mm

Quantity

Box/Bag

Ø

i

B

M N d

D i m e n s i o n s m m

Ref.

400 R

600 R ÷ 630 R

HT 120

and tools

and heads

with

130 kN

crimping

force

ECW-H3D

RHU 520

HIGH VOLTAGE HEAVY DUTY COPPER TERMINALS

two hole fixing

CA-2M

2A-2M/55°

Hydraulic

Tools

8

CA 25-2 M 8

6,8 14,0 10

11 113,5

8,4

12

CA 25-2 M 12

6,8 21,0 16

14 122,5 13,2

8

CA 25-2 M 8

6,8 14,0 10

11 113,5

8,4

10

CA 25-2 M 10

6,8 18,0 13

11 116,5 10,5

12

CA 25-2 M 12

6,8 21,0 16

14 122,5 13,2

12

CA 40 S-2 M 12

8,2 21,5 16

14 123,5 13,2

12

CA 35-2 M 12

8,25 21,5 16

14 123,5 13,2

12

CA 50 R-2 M 12

8,7 20,5 16

14 123,5 13,2

12

CA 50 S-2 M 12

9,5 21,0 16

14 123,5 13,2

12

CA 50-2 M 12

9,5 21,0 16

14 123,5 13,2

12

CA 70 S-2 M 12

11,0 27,0 16

14 127,7 13,2

12

CA 70 S-2 M 12

11,0 27,0 16

14 127,7 13,2

14

CA 95 R-2 M 14

12,0 28,0 18

16 139,5 15,0

14

CA 95 S-2 M 14

13,5 29,0 18

16 139,5 15,0

12

CA 95-2 M 12

13,5 28,0 16

14 135,5 13,2

14

CA 150 R-2 M 14

15,0 31,0 18

16 145,5 15,0

12

CA 120-2 M 12

15,0 31,0 16

14 141,5 13,2

14

CA 150 S-2 M 14

16,5 32,0 18

16 145,5 15,0

12

CA 150-2 M 12

16,5 32,0 16

14 141,5 13,2

14

CA 200 R-2 M 14

17,0 32,5 18

16 145,0 15,0

12

CA 185-2 M 12

18,0 32,5 16

14 141,5 13,2

14

CA 240 R-2 M 14

19,2 43,0 18

16 151,5 15,0

14

CA 315 R-2 M 14

21,5 43,0 18

16 149,5 15,0

12

CA 240-2 M 12

20,5 43,0 16

14 147,5 13,2

12

CA 300-2 M 12

23,0 43,0 16

14 145,5 13,2

14

CA 315 S-2 M 14

23,7 44,0 18

16 149,5 15,0

Conductor Size

(sqmm)

& Format

Ø

Stud

mm

Quantity

Box/Bag

Ø

i

B

M N L

d

D i m e n s i o n s m m

Ref.

25 R

25 BR/BS*

30 RC/S ÷ 40 S

35 BR/BS*

50 RC

50 S

50 BR/BS*

63 S ÷ 70 S

70 BR/BS*

80 S ÷ 95 RC

95 S ÷ 100 S

95 BR/BS*

120 RC/S ÷ 150 RC

120 BR/BS*

150 S ÷ 160 RC

150 BR/BS*

160 S ÷ 200 RC

185 BR/BS*

200 S ÷ 240 RC

240 S ÷ 315 RC

240 BR/BS*

300 BR/BS*

315 S

Conductor Format: R = Round, RC = Round Compact, S = Sector, BR = IEC228 (BS6360) Round, BS* = IEC228 (BS6360) Sector

* = Pre-rounding required, consult Cembre for appropriate die set

HT 81-U RHU 81

HT 120 and tools and heads with 130 kN crimping force

ECW-H3D

RHU 520

HT 51 RH 50 B 500E B 550E

B35-50MDE

HIGH VOLTAGE TERMINALS

two hole fixing - 55°