44

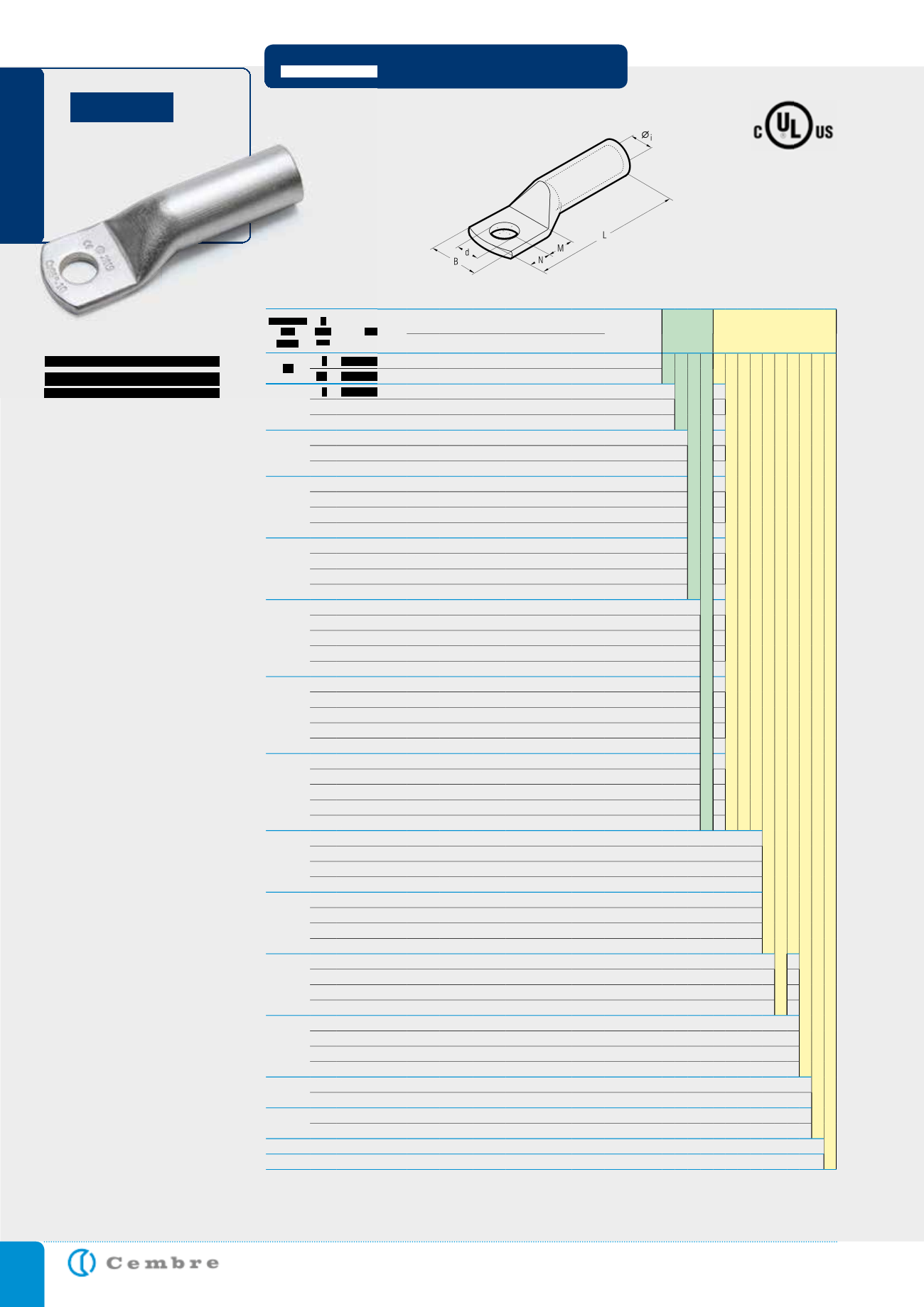

2A-M series terminals

are made from high purity

Copper tube, and are an-

nealed.

They feature a double

length barrel for enhanced

electrical and mechanical

performance in heavy duty

applications.

The absence of an inspec-

tion hole prevents the entry

of water or moisture into

the crimped joint making

these terminals suitable for

outdoor applications.

The terminals are electro-

lytically Tin plated to prevent

atmospheric corrosion.

Details of the appropriate

crimping tools and dies

are shown on pages 180

to 181.

2A-M

HIGH VOLTAGE TERMINALS

Conductor

Size

sqmm

Ø

Stud

mm

Ref.

D i m e n s i o n s m m

Quantity

Box/Bag

Mechanical

Tools

Hydraulic

Tools

Øi

B

M N L

d

2 A 3-M 8

5,8 15,0 9,0 8,0 43,5 8,4

600/100

HN5

HN-A25

TN 70 SE

TN 120 SE*

B 15MDE

B 35-45MDE

B 35-50MDE

HT 45-E

HT 51 B 550E

RH 50 B 500E

HT 81-U RHU 81

HT 120 and tools and heads with 130 kN crimping force

ECW-H3D

RHU 520

2 A 3-M10

5,8 18,0 11,0 10,0 47,5 10,5

500/100

25

2 A 5-M 8

7,0 15,0 9,0 8,0 51,0 8,4

400/100

10

2 A 5-M 10

7,0 18,0 11,0 10,0 55,0 10,5

300/50

12

2 A 5-M 12

7,0 21,0 14,0 12,0 60,0 13,2

300/50

35

8

2 A 7-M 8

8,9 17,0 9,0 8,0 53,0 8,4

250/50

10

2 A 7-M 10

8,9 19,0 11,0 10,0 57,0 10,5

250/50

12

2 A 7-M 12

8,9 21,0 14,0 12,0 62,0 13,2

200/50

50

10

2 A 10-M 10

10,0 20,0 11,0 10,0 63,0 10,5

200/50

12

2 A 10-M 12

10,0 21,0 14,0 12,0 68,0 13,2

150/50

14

2 A 10-M 14

10,0 25,0 16,0 14,0 72,0 15,0

150/50

16

2 A 10-M 16

10,0 26,0 18,0 16,0 76,0 17,0

150/50

63

70

10

2 A 14-M 10

11,3 21,0 11,0 10,0 70,0 10,5

100/50

12

2 A 14-M 12

11,3 22,0 14,0 12,0 75,0 13,2

100/50

14

2 A 14-M 14

11,3 25,0 16,0 14,0 79,0 15,0

100/50

16

2 A 14-M 16

11,3 26,0 18,0 16,0 83,0 17,0

100/50

95

10

2 A 19-M 10

13,5 25,0 11,0 10,0 76,5 10,5

75/25

12

2 A 19-M 12

13,5 25,0 14,0 12,0 81,5 13,2

75/25

14

2 A 19-M 14

13,5 25,0 16,0 14,0 85,5 15,0

75/25

16

2 A 19-M 16

13,5 27,0 18,0 16,0 90,5 17,0

75/25

20

2 A 19-M 20

13,5 29,5 22,0 20,0 97,5 21,0

75/25

120

125

10

2 A 24-M 10

15,2 28,5 11,0 10,0 82,0 10,5

50/25

12

2 A 24-M 12

15,2 28,5 14,0 12,0 87,0 13,2

50/25

14

2 A 24-M 14

15,2 28,5 16,0 14,0 91,0 15,0

50/25

16

2 A 24-M 16

15,2 28,5 18,0 16,0 95,0 17,0

50/25

20

2 A 24-M 20

15,2 30,0 22,0 20,0 103,0 21,0

50/25

150

10

2 A 30-M 10

16,7 31,5 13,0 11,0 92,0 10,5

50/25

12

2 A 30-M 12

16,7 31,5 16,0 14,0 98,0 13,2

30/15

14

2 A 30-M 14

16,7 31,5 18,0 16,0 102,0 15,0

30/15

16

2 A 30-M 16

16,7 31,5 19,0 17,0 104,0 17,0

30/15

20

2 A 30-M 20

16,7 31,5 22,0 20,0 110,0 21,0

30/15

185

12

2 A 37-M 12

19,2 35,5 16,0 14,0 108,0 13,2

30/15

14

2 A 37-M 14

19,2 35,5 18,0 16,0 112,0 15,0

30/15

16

2 A 37-M 16

19,2 35,5 19,0 17,0 114,0 17,0

30/15

20

2 A 37-M 20

19,2 35,5 22,0 20,0 120,0 21,0

30/15

240

12

2 A 48-M 12

21,1 39,0 16,0 14,0 109,0 13,2

20/5

14

2 A 48-M 14

21,1 39,0 18,0 16,0 113,0 15,0

20/5

16

2 A 48-M 16

21,1 39,0 19,0 17,0 115,0 17,0

20/5

20

2 A 48-M 20

21,1 39,0 22,0 20,0 121,0 21,0

25/5

300

12

2 A 60-M 12

23,7 44,0 20,0 14,0 129,5 13,2

20/5

14

2 A 60-M 14

23,7 44,0 22,0 16,0 133,5 15,0

20/5

16

2 A 60-M 16

23,7 44,0 22,0 19,0 136,5 17,0

20/5

20

2 A 60-M 20

23,7 44,0 24,0 23,0 142,5 21,0

20/5

400

12

2 A 80-M 12

27,0 51,0 22,0 19,0 140,0 13,2

15/5

14

2 A 80-M 14

27,0 51,0 22,0 19,0 140,0 15,0

10/5

16

2 A 80-M 16

27,0 51,0 22,0 19,0 140,0 17,0

10/5

20

2 A 80-M 20

27,0 51,0 24,0 23,0 146,0 21,0

15/5

500

16

2 A 100-M 16

30,3 56,5 22,0 19,0 147,0 17,0

10/1

20

2 A 100-M 20

30,3 56,5 24,0 23,0 153,0 21,0

10/1

630

16

2 A 120-M 16

33,4 61,5 22,0 19,0 159,0 17,0

20/1

20

2 A 120-M 20

33,4 61,5 24,0 23,0 165,0 21,0

20/1

800 20

2 A 160-M 20

38,0 72,0 24,0 23,0 187,0 21,0

12/1

1000 20

2 A 200-M 20

44,0 82,0 24,0 23,0 202,0 21,0

6/1

16

8

10

8

*See page 109

Not UL approved

File no. E125401