54

The barrels of series CAA-M

connectors are made from

Aluminium of a purity equal

to or greater than 99,5%.

The barrel is friction welded

to the palm thus achieving

the best possible transition

between the copper palm

and Aluminium barrel.

Barrels are capped and

filled with grease so as to

avoid oxidation of the Alu-

minium.

Details of the appropriate

crimping tools and dies are

shown on pages 185, 187.

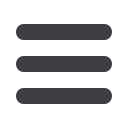

BIMETALLIC CONNECTORS

copper palm fixing

Aluminium barrels

The barrels of series MTA-C

connectors are made from

Aluminium of a purity equal

to or greater than 99,5%.

The barrel is friction welded

to the pin thus achieving

the best possible transi-

tion between the copper

pin and Aluminium barrel.

Barrels are capped and

filled with grease so as to

avoid oxidation of the Alu-

minium.

Details of the appropriate

crimping tools and dies are

shown on pages 185, 187.

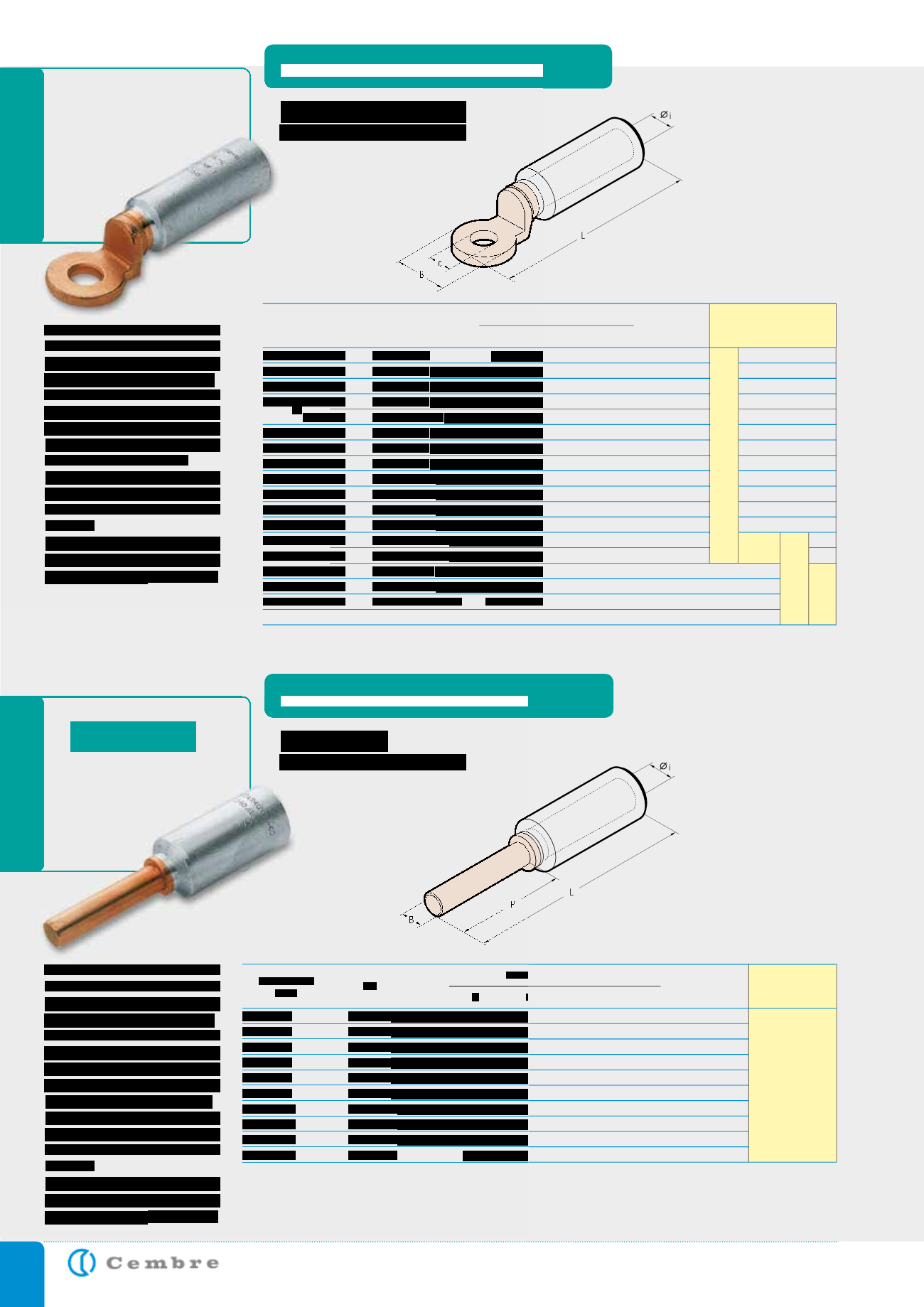

BIMETALLIC CONNECTORS

copper pin

Aluminium barrels

Hydraulic

Tools

16

MTA 16-C

5,5

8

30

82

25

MTA 25-C

6,5

8

30

82

35

MTA 35-C

8,0

8

30

82

50

MTA 50-C

9,0

12

45

97

70

MTA 70-C

11,0

12

45

97

95

MTA 95-C

12,5

12

45

97

120

MTA 120-C

13,7

14

55

125

150

MTA 150-C

15,5

14

55

125

185

MTA 185-C

17,0

14

55

125

240

MTA 240-C

19,5

14

55

125

90/3

90/3

90/3

60/3

60/3

60/3

30/3

30/3

24/3

24/3

Conductor Size

sqmm

Quantity

Box/Bag

L

P

B

Øi

D i m e n s i o n s m m

Ref.

HT 131-UC

RHU 131-C

B 1300-UCE

CAA-M

MTA-C

Hydraulic

Tools

10

12

CAA 10-M 12

4,3

24

87,0

13,0

16

12

CAA 16-M 12

5,5

24

87,0

13,0

25

12

CAA 25-M 12

6,5

24

87,0

13,0

12

CAA 35-M 12

8,0

24

87,0

13,0

35

12

CAA 35-20-M 12

8,0

24

87,0

13,0

50

12

CAA 50-M 12

9,0

24

87,0

13,0

70

12

CAA 70-M 12

11,0

24

87,0

13,0

95

12

CAA 95-M 12

12,5

24

87,0

13,0

120

12

CAA 120-M 12

13,7

31

111,0

13,0

150

12

CAA 150-M 12

15,5

31

111,0

13,0

185

12

CAA 185-M 12

17,0

35

116,0

13,0

240

12

CAA 240-M 12

19,5

35

116,0

13,0

12

CAA 300-34 M 12

22,5

35

120,0

13,0

300

16

CAA 300-34 M 16

22,5

35

120,0

17,0

16

CAA 300-M 16

23,3

35

152,5

16,5

400

16

CAA 400-M 16

26,0

35

152,5

16,5

500

16

CAA 500-M 16 TNBD

29,1

35

152,5

16,5

630

8

CAA 630-4 M 8

32,5

60

192,0 4 x 9,0*

90/3

90/3

90/3

90/3

60/3

60/3

60/3

60/3

30/3

30/3

18/3

18/3

15/3

15/3

12/3

12/3

12/3

9/3

Conductor Size

sqmm

Ø

Stud

mm

Quantity

Box/Bag

d

L

B

Øi

D i m e n s i o n s m m

Ref.

RHU 230-630

HT120

HT131-C

RHC 131

HT 131-UC RHU 131-C B 1300-UCE

ECW-H3D

* 4 holes with 30 mm between axes