Furse, Wilford Road, Nottingham, NG2 1EB • Tel: +44 (0)115 964 3700 • Email:

enquiry@furse.com• Web:

www.furse.comTSC-0912 - 09.10.12

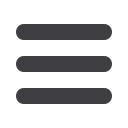

Earth electrodes

Driving stud

Threaded

coupling

Rod

Earth rods to BS EN 50164-2, BS 7430

Fittings to BS EN 50164-1

†

UL467 (RB125, RB225, RB235, RB325, RB335, CG270, CG370)

Nominal

diameter

Length

Thread

‘B’ UNC

Shank

‘A’

Weight

Part

each

No.

1

⁄

2

”

1200 mm

9

⁄

16

”

12.7 mm 1.18 kg

RB105

1

⁄

2

”

1500 mm

9

⁄

16

”

12.7 mm 1.55 kg

RB110

1

⁄

2

”

1800 mm

9

⁄

16

”

12.7 mm 1.76 kg

RB115

1

⁄

2

”

2400 mm

9

⁄

16

”

12.7 mm 2.36 kg

RB125

†

5

⁄

8

”

1200 mm

5

⁄

8

”

14.2 mm 1.53 kg

RB205-FU

5

⁄

8

”

1500 mm

5

⁄

8

”

14.2 mm 1.88 kg

RB210

5

⁄

8

”

1800 mm

5

⁄

8

”

14.2 mm 2.29 kg

RB215

5

⁄

8

”

2100 mm

5

⁄

8

”

14.2 mm 2.51 kg

RB220-FU

5

⁄

8

”

2400 mm

5

⁄

8

”

14.2 mm 3.00 kg

RB225

†

5

⁄

8

”

3000 mm

5

⁄

8

”

14.2 mm 3.79 kg

RB235

†

3

⁄

4

”

1200 mm

3

⁄

4

”

17.2 mm 2.19 kg

RB305

3

⁄

4

”

1500 mm

3

⁄

4

”

17.2 mm 2.73 kg

RB310

3

⁄

4

”

1800 mm

3

⁄

4

”

17.2 mm 3.27 kg

RB315

3

⁄

4

”

2100 mm

3

⁄

4

”

17.2 mm 3.83 kg

RB320-FU

3

⁄

4

”

2400 mm

3

⁄

4

”

17.2 mm 4.35 kg

RB325

†

3

⁄

4

”

3000 mm

3

⁄

4

”

17.2 mm 5.44 kg

RB335

†

Fittings

Type

Weight

Part

each

No.

1

⁄

2

” Coupling

0.09 kg

CG170

5

⁄

8

” Coupling

0.08 kg

CG270

†

3

⁄

4

” Coupling

0.13 kg

CG370

†

1

⁄

2

” Driving stud

0.05 kg

ST100

5

⁄

8

” Driving stud

0.08 kg

ST200

3

⁄

4

” Driving stud

0.12 kg

ST300

Threaded copperbond earth rod

Furse copperbond earth rods probably offer to the installer the best and

most economical earth rods available. They are made by molecularly

bonding 99.9% pure electrolytic copper on to a low carbon steel core.

Furse rods are not of the sheathed type.

They are highly resistant to

corrosion, and because the steel used has a very high tensile strength,

they can be driven by power hammers to great depths.

The counter-bored couplings are made from high copper content alloy,

commercial brass is not used

. This again ensures excellent corrosion

resistance and high strength.

Copper thickness minimum 250 microns.

RB225 + ST200 +

CG270

A

B