TECHNICAL INFORMATION

Technical information

Wire Basket

| 255

18

The distance between supports is of 1.2 m and

the maximum load is of 10 kg/m.

The systemmay have one or two levels.

Earth bonding

For earth bonding requirements please refer to

the currentWiring Regulations BS7671 and all

current amendments.

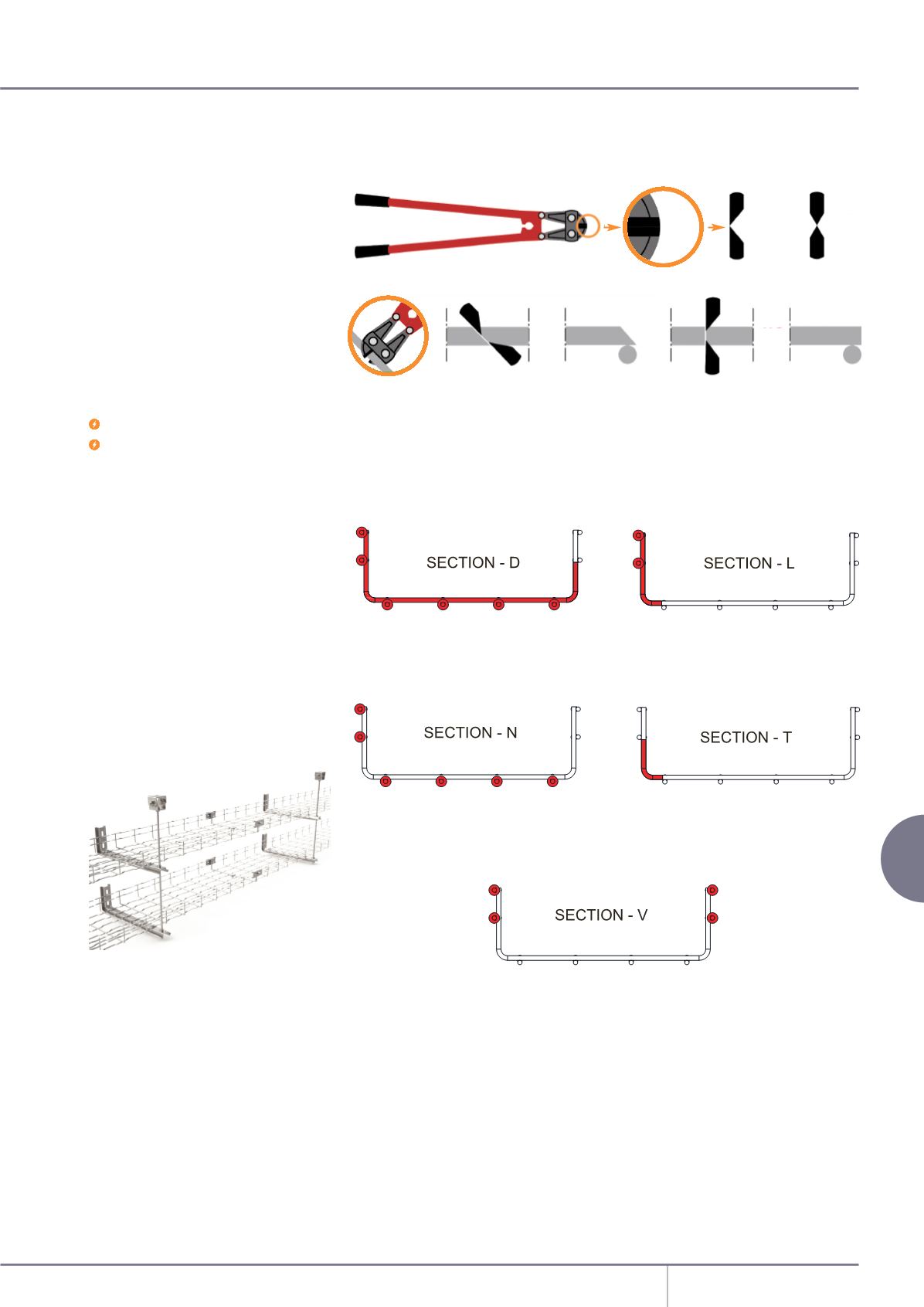

Cutting

Always use asymmetrical cut wire cutters. Cut as close as you can to where horizontal and vertical

rods cross each other, as shown.

We recommend always placing the basket on a flat surface to make the cuts.

The below drawings show in red the section cuts that are needed for the bends, tees and

changing levels as explained in the Installation section on pages 97-99.

EMC and Data

It is recommended to separate power and

data circuits by a minimum of 20cm.

(EN 50174-2)

Where power and data circuits must cross, this

must be done at 90 degrees.

Wire Basket systems without electrical

continuity do not protect against

electromagnetic fields. Make sure electrical

continuity is preserved by using the

appropriate earth bonding accessories.

Electrical continuity

Our Fast-CouplingWire Basket conforms to IEC

61537. The wire mesh basket has an

impedance lower than:

50mΩ across the joint

5mΩ per metre in a straight section

Fire Resistance

Marshall-Tuex and Basor Electric certifies

that the wire basket installed with the

below mentioned characteristics complies

with Class E90 of functionmaintenances, in

accordance with Standard DIN 4102, Section

12.

This system incorporates StandardWire Basket

with a height of 65mm. This system uses Fast

FixWall Bracket supports fixed to the wall and

reinforced on the ceiling using the Variable

Support Bracket, M8 Threaded Rod and M8

Nut on one side, as per the below image.

45

o

OK

NO

OK

NO