TECHNICAL INFORMATION

Technical information

Wire Basket

| 253

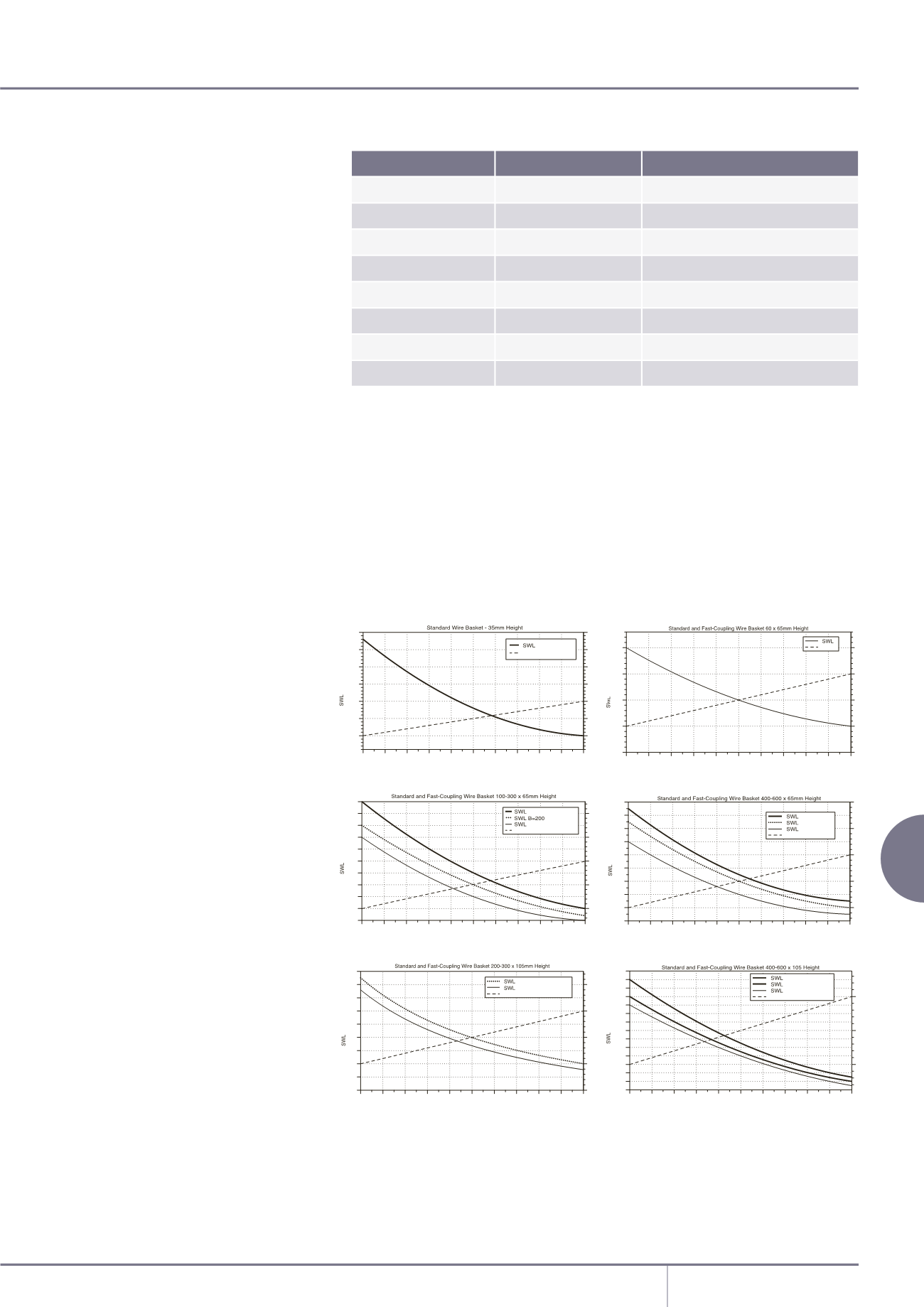

Safe working load (SWL)

The safe working load (SWL) is the maximum load which can be applied during normal use,

without danger. Therefore, the workload shall always be less than the SWL.

The SWL of our products are calculated in accordance with IEC 61537. For any further

information contact our Technical Team in +44 (0)1424 856688.

To show the installation designer the level of ventilation allowed for the cable tray, the IEC 61537

standard established that the manufacturer has to inform of the percentage of the base 'free'

(without material, in solid cable trays this means the "degree of perforation").

16

Atmospheric Corrosion

Atmospheric corrosion happens when

metal is exposed to liquids, solids or gases,

Humidity, salt corrosive gases and dirt are

its main factors. Atmospheric corrosion

takes place in open air conditions, areas

with poor ventilation and marine

environments.

Saline corrosion happens when a metallic

surface is exposed to dierent saline

concentration levels forming a galvanic

pile. At times where the surface is exposed

to the lowest degree of saline

concentration this will then behave as an

anode for the corrosion to take place.

Chemical Corrosion

Chemical corrosion happens when metal is

directly exposed to chemical solutions.

Depending on the concentration of the

solution, contact time , cleaning frequency

and ambient temperature the level of

corrosion will be higher or lower.

Galvanic Corrosion

Galvanic corrosion is the most common

type of corrosion, and happens when two

dierent metals are in contact with one

another. When two dierent metals come

into contact a small galvanic par is created,

as one metal acts as an anode the other

acts as a cathode. The metal with the most

negative reduction potential shall oxidise

whilst the metal with the most positive

charge shall have less corrosion.

Storage Conditions

The product must be stored in a dry and

well ventilated area. The product must not

be stored outside even in low humidity

conditions.

Resistance to corrosion

Free Base Area

Base size

Classification

Free base area

60

Z

More than 90%

100

Y

Over 80% and up to 90%

150

Y

Over 80% and up to 90%

200

Y

Over 80% and up to 90%

300

Y

Over 80% and up to 90%

400

Y

Over 80% and up to 90%

500

Y

Over 80% and up to 90%

600

Y

Over 80% and up to 90%

10

15

20

25

30

B=300

B=100..150

Def

20

25

30

35

40

45

50

55

60

65

70

d (m)

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

(Kg/m)

Def (mm)

5

10

15

20

25

300x105

200x105

Def

20

30

40

50

60

70

80

90

100

110

d (m)

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

10

15

20

25

30

B=600

B=500

B=400 Def

30

40

50

60

70

80

90

100

110

120

d (m)

1.0

1.1 1.2

1.3 1.4

1.5 1.6

1.7 1.8

1.9 2.0

10

15

20

B=600

B=500

B=400

Def

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

d (m)

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

5

10

15

20

25

Def

5

10

15

20

25

d (m)

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

10

15

20

25

30

35

40

Def

10

15

20

25

30

35

40

d (m)

1.0

1.1

1.2

1.3

1.4

1.5 1.6

1.7

1.8

1.9

2.0

Def (mm)

(Kg/m)

Def (mm)

(Kg/m)

Def (mm)

(Kg/m)

Def (mm)

(Kg/m)

(Kg/m)

Def (mm)